Explosion-proof plate for metal zinc oxide arrester of corrugated structure

An explosion-proof plate and arrester technology, applied in the direction of overvoltage protection resistors, varistors, etc., can solve the problems of difficulty in measuring the internal pressure of explosion-proof plates, damage to the air tightness of the air chamber, and complicated production, and achieve thermal conductivity and electrical conductivity. Excellent, long service life and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

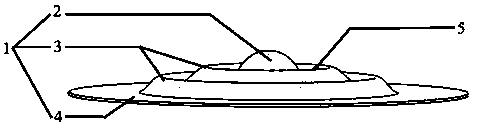

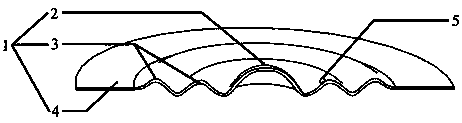

[0029] When the explosion-proof panel 1 is used, such as Figure 7 As shown, it is fixedly installed on the top of the arrester, and the interior of the arrester is filled with high-purity N 2 or SF 6 Gas, its internal pressure is higher than the external atmospheric pressure, the pressure difference is about 0.03 ~ 0.05MPa. The edge of the explosion-proof plate 1 forms a seal with the top of the arrester, and the explosion-proof plate 1 is as figure 2 The state shown is convex, and the strain gauge 5 is in the reference deformation state at this moment.

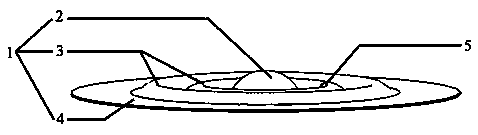

[0030] When the internal pressure of the arrester leaks, the deformation of the explosion-proof plate 1 will decrease. At this time, the explosion-proof plate 1 is as figure 1 In the state shown, the deformation of the annular corrugated protrusion 3 of the explosion-proof plate 1 is reduced, and the deformation detected by the strain gauge 5 laid on it is correspondingly reduced, and the deformation amount of the strain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com