Self-pressurizing cryoablation system

A self-pressurization and ablation catheter technology, which is applied in the direction of cooling surgical instruments, can solve the problems of large space and increase the difficulty of installation and operation of the cryoablation system, achieve long-lasting storage performance, avoid pressurization and adjustment difficulties, and have high controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

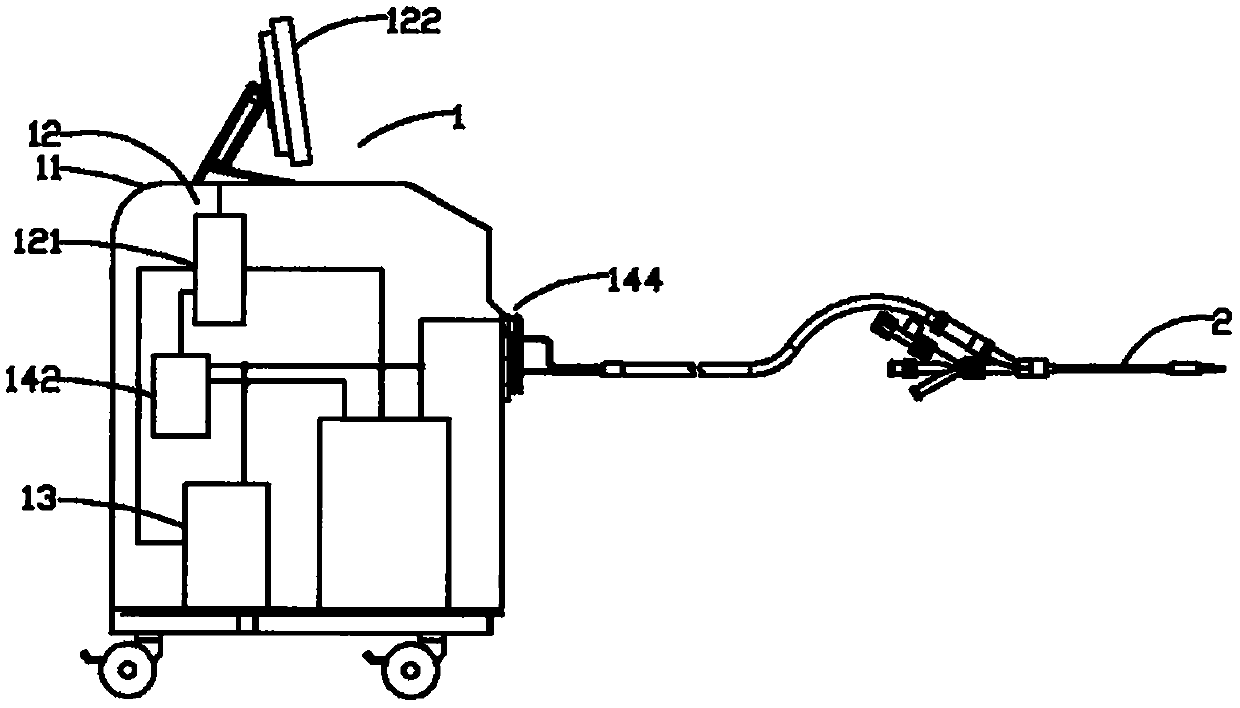

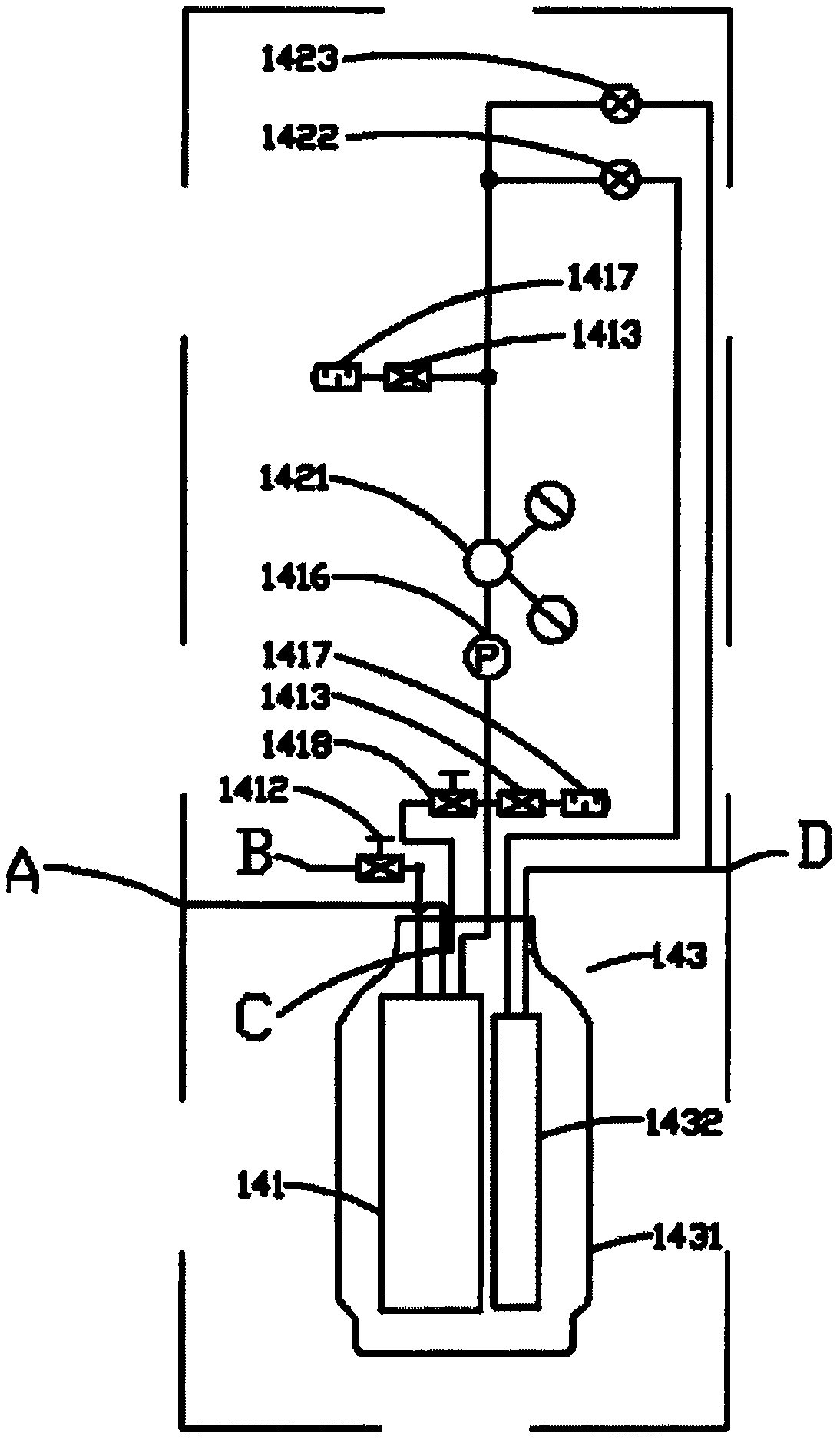

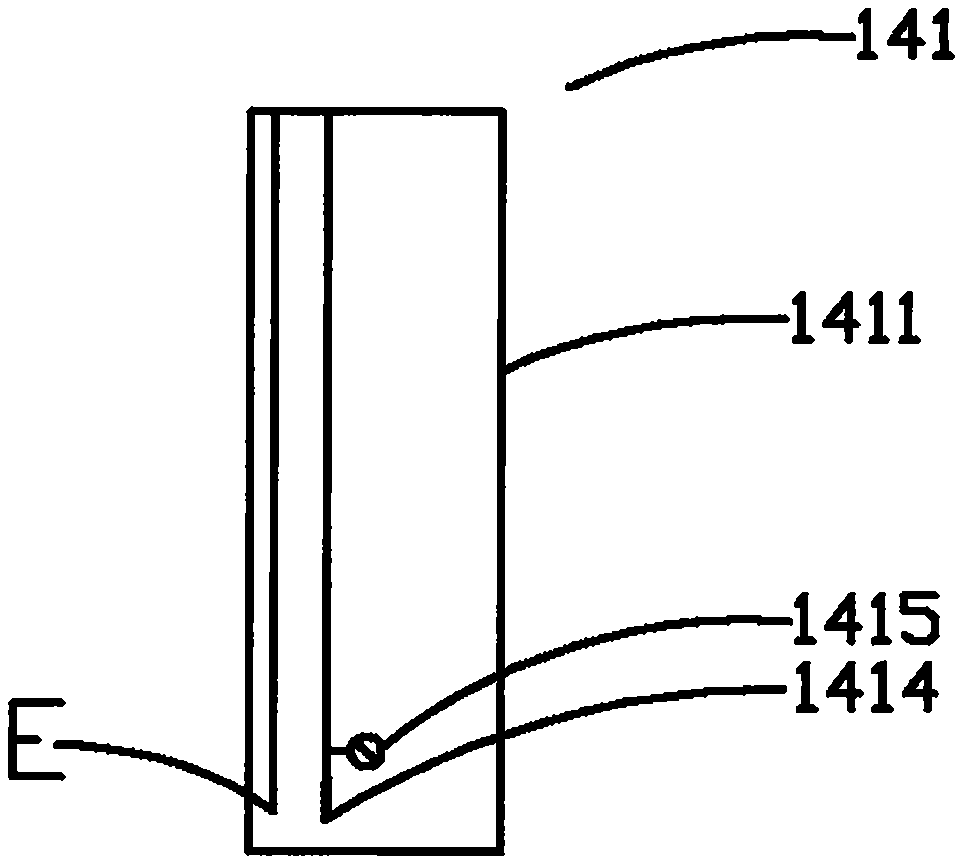

[0028] Such as figure 1 , 2 As shown in and 3, the self-pressurized cryoablation system of the present invention includes a cryoablation device 1 and a cryoablation catheter 2, the cryoablation device 1 includes a housing 11, a control unit 12, a vacuum unit 13 and a delivery unit 14, the The conveying unit 14 includes a gas source manufacturing device 141, a gas path control device 142, a low temperature conversion device 143 and an equipment connection 144 connected in sequence, and the gas outlet of the equipment connection 144 and the vacuum unit 13 are respectively connected to the freezer. The ablation catheter 2 is in fluid communication, the low temperature conversion device 143 includes a Dewar bottle 1431 and a heat exchanger 1432, the gas source manufacturing device 141 is arranged in the Dewar bottle 1431, and the gas outlet of the gas source manufacturing device 141 end is in fluid communication with the intake end 1421 of the gas circuit control device 142, the ...

Embodiment 2

[0035] Such as Figure 4 , 5 As shown in and 6, this embodiment is based on the first embodiment, the difference of the first embodiment is only that the structure of the heat exchanger 1432 is different. Such as Figure 4 As shown, the heat exchanger 1432 is a spiral tube structure, which increases the heat exchange area between the gaseous coolant and the coolant in the Dewar 1431, and the spiral tube structure can effectively reduce the flow of the coolant in the heat exchanger 1432. flow resistance within; Figure 5 As shown, the heat exchanger 1432 is a horizontal serpentine tube structure, which increases the heat exchange area for energy exchange between the gaseous coolant and the liquid coolant in the Dewar bottle 1431, and can reduce the heat exchange rate of the heat exchanger in the Dewar bottle 1431 as much as possible. Inner space consumption, improve system compactness; such as Image 6 As shown, the heat exchanger 1432 is a vertical serpentine tube structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com