Three-layer co-extrusion machine head for double-color quartered insulation cable

An insulated cable and three-layer co-extrusion technology, which is applied in the field of three-layer co-extrusion heads, can solve the problems of low production efficiency of yellow-green grounding wires, inability to meet two-color four-part co-extrusion, inconvenience in installation, use, and maintenance, and achieve Simple structure, uniform thickness, uniform extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

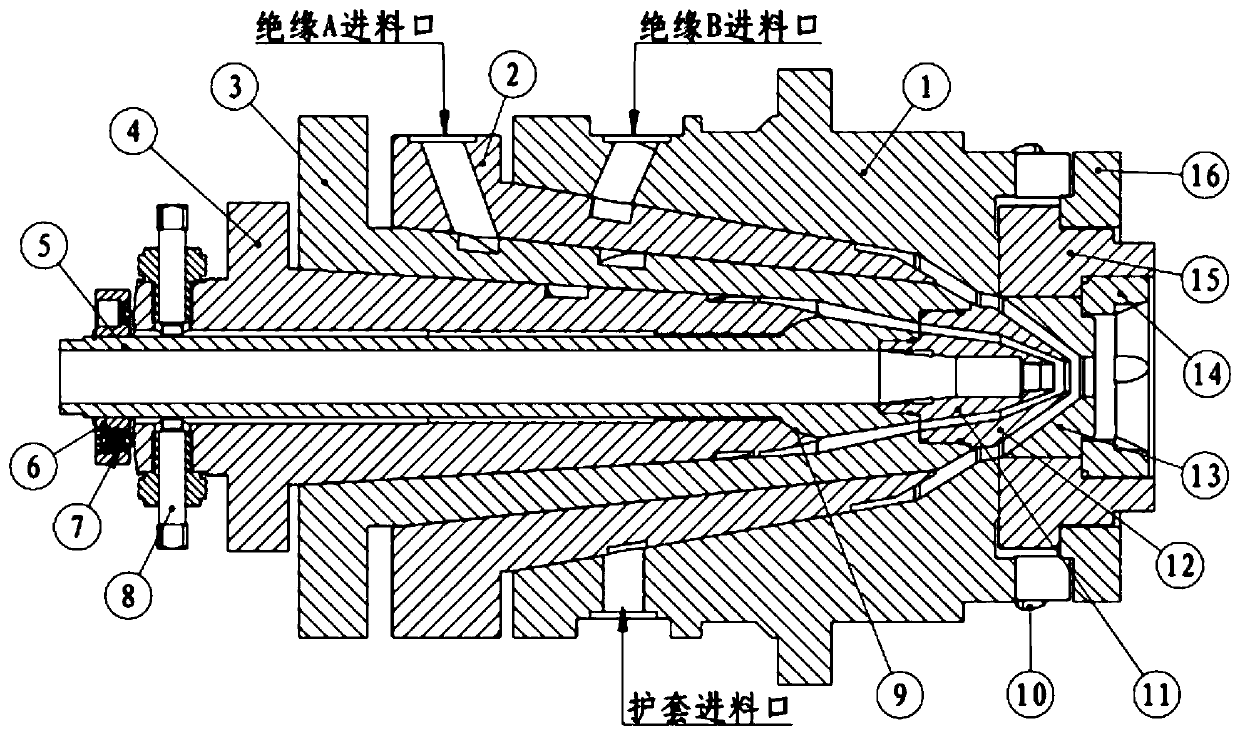

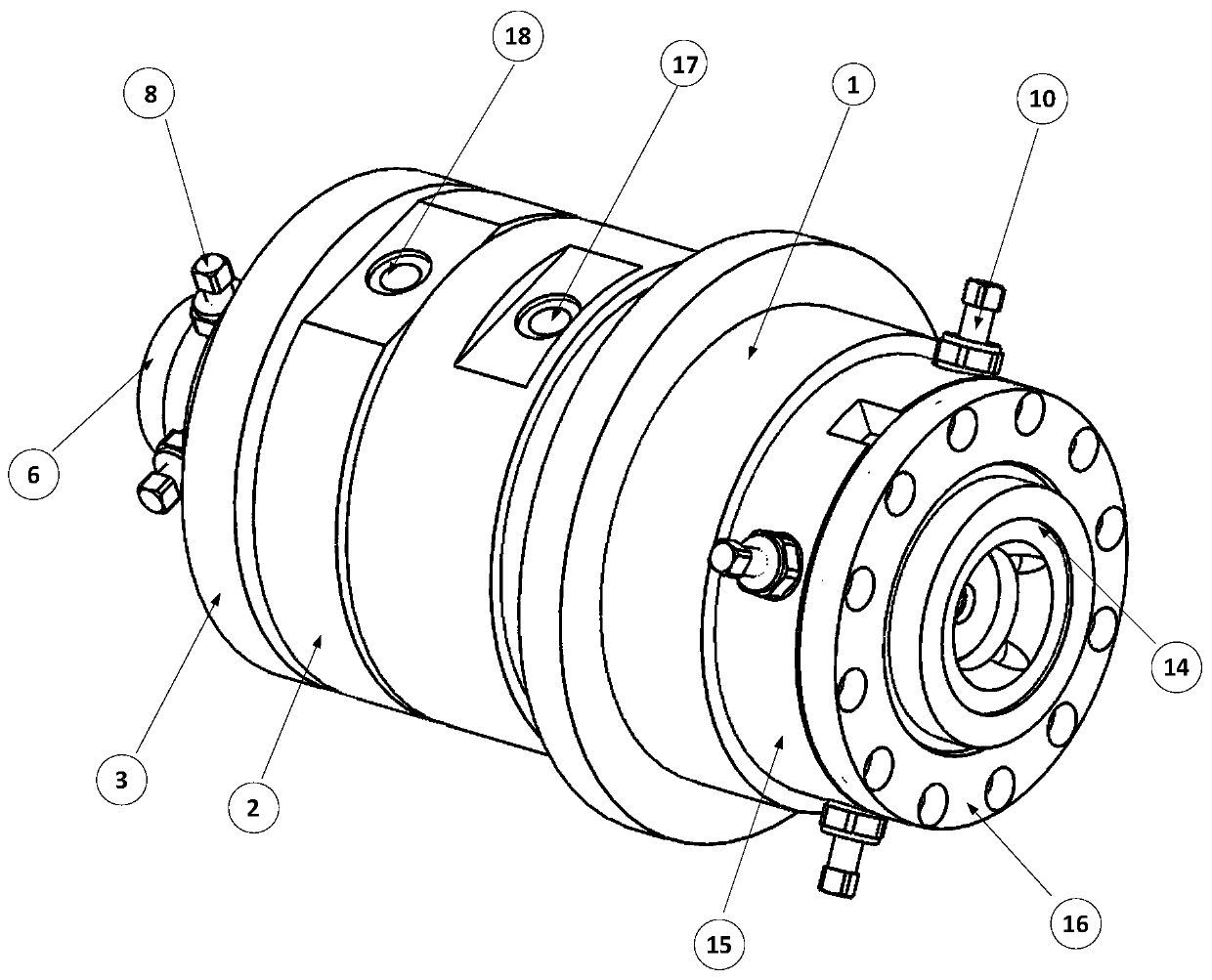

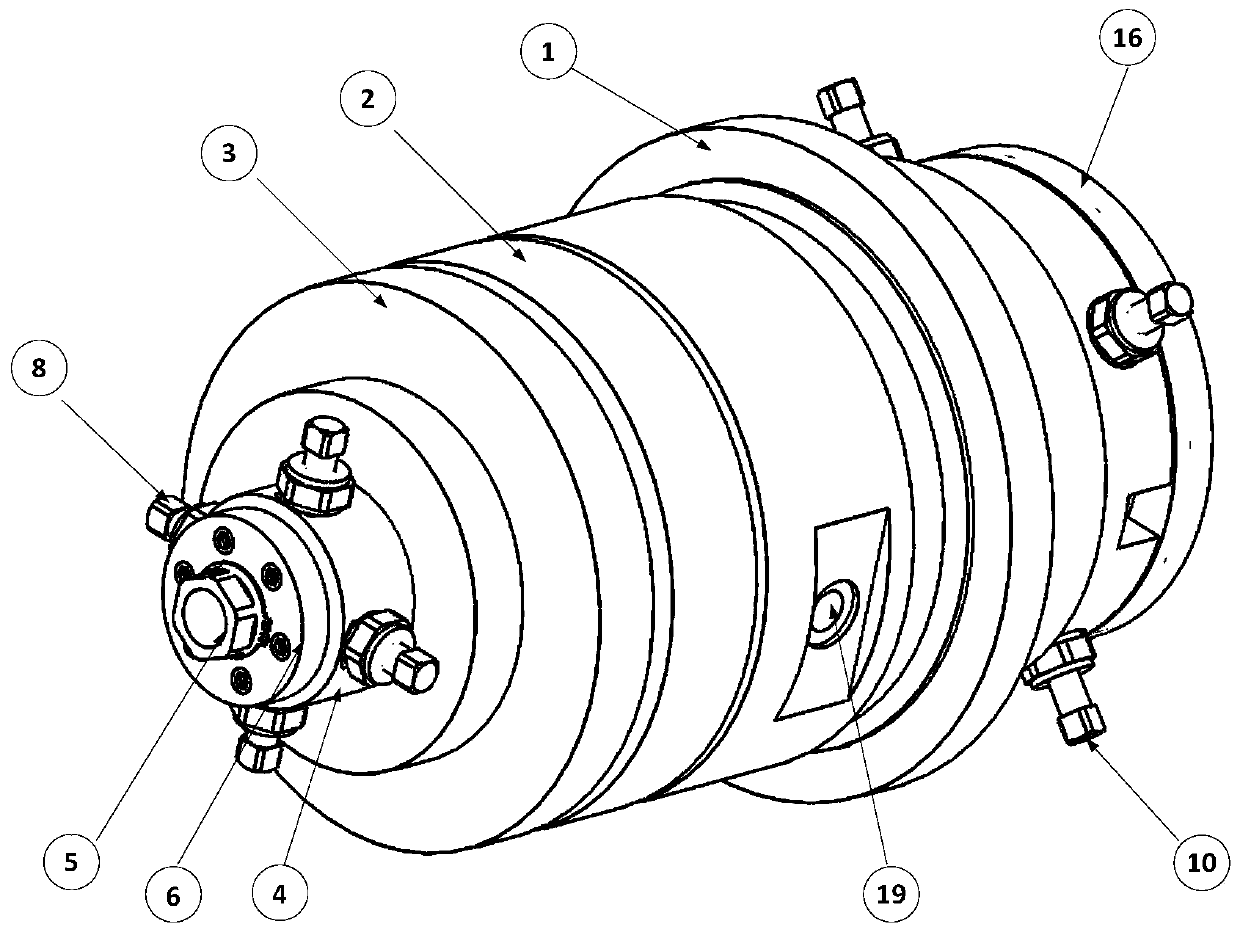

[0061] Such as Figure 1 to Figure 20 As shown, this embodiment provides a three-layer co-extrusion head for two-color four-point insulated cables. It should be noted that the serial numbers such as "first" and "second" described in this embodiment are only used to distinguish Parts of the same kind shall not be understood as a specific limitation on the scope of protection. In addition, directional terms such as "bottom", "top", "surrounding edge", and "center" in this embodiment are described based on the drawings. Not only that, the structure and composition of the product protected by the present invention can be designed according to the corresponding size of the cable core, which will not be described in detail here.

[0062] In this embodiment, the three-layer co-extrusion head includes a built-in conical hollow casing 1, which is inserted into the conical hollow of the casing 1 along the feeding direction of the cable conductor, and the outer surface edge and the casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com