Kitchen paper prepared by regenerating and utilizing Qianjinfang medicine residue resources, and preparation method thereof

A kitchen paper and resource regeneration technology, applied in the field of kitchen paper, can solve the problem of insufficient antibacterial and sterilizing functions, and achieve the effects of high functional characteristics and added value, improving tensile strength, and good antibacterial and sterilizing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

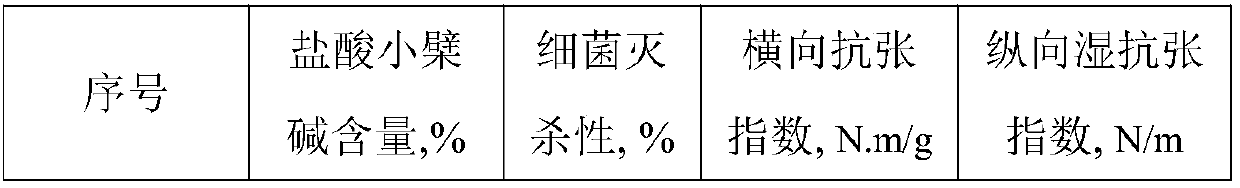

Examples

Embodiment 1

[0036] A method for preparing kitchen paper by recycling Qianjinfang herbal dregs resources, comprising the following steps:

[0037] S1. Cooking: put Qianjinfang medicine dregs with a water content of 25% in a digester, add ethanol solution with a concentration of 40%, and the liquid ratio is 1:4, quickly heat up to 100°C, keep warm for 120 minutes, and then discharge. Obtain coarse stock and cooking liquid;

[0038] S2. Washing: Place the coarse slurry obtained in step S1 in a displacement washer, and perform three-stage displacement washing with an ethanol solution with a concentration of 55%, the washing liquid ratio is 1:7, and the washing temperature is 40°C; then wash with water Clean and dry to obtain fiber semi-finished products;

[0039] S3. Expansion: the fiber semi-finished product obtained in step S2 is placed in an extruder for expansion treatment, the expansion temperature is 100° C., and the expansion time is 20 minutes to obtain expanded dregs fiber;

[0040...

Embodiment 2

[0045] A method for preparing kitchen paper by recycling Qianjinfang herbal dregs resources, comprising the following steps:

[0046] S1. Cooking: put Qianjinfang medicine dregs with a water content of 45% in a digester, add ethanol solution with a concentration of 60%, and the liquid ratio is 1:9, quickly heat up to 140°C, keep warm for 60 minutes, and then discharge. Obtain coarse stock and cooking liquor;

[0047] S2. Washing: Place the coarse slurry obtained in step S1 in a displacement washer, perform three-stage displacement washing with an ethanol solution with a concentration of 70%, the washing liquid ratio is 1:10, and the washing temperature is 60°C; then wash with water Clean and dry to obtain fiber semi-finished products;

[0048]S3. Expansion: the fiber semi-finished product obtained in step S2 is placed in an extruder for expansion treatment, the expansion temperature is 120° C., and the expansion time is 10 minutes to obtain expanded dregs fiber;

[0049] S4....

Embodiment 3

[0054] A method for preparing kitchen paper by recycling Qianjinfang herbal dregs resources, comprising the following steps:

[0055] S1. Cooking: put the medicinal dregs of Qianjin Recipe with a water content of 35% in a digester, add ethanol solution with a concentration of 53%, and the liquid ratio is 1:7, quickly heat up to 120°C, and discharge the material after holding the heat for 80 minutes to obtain Coarse stock and cooking liquor;

[0056] S2. Washing: Place the coarse slurry obtained in step S2 in a displacement washer, perform three-stage displacement washing with an ethanol solution with a concentration of 60%, the washing liquid ratio is 1:9, and the washing temperature is 50°C; then wash with water Clean and dry to obtain fiber semi-finished products;

[0057] S3. Expansion: the fiber semi-finished product obtained in step S2 is placed in an extruder for expansion treatment, the expansion temperature is 110° C., and the expansion time is 15 minutes to obtain ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com