Mold plate construction method for floor and temporary road concrete casting

A technology for temporary roads and concrete, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems that affect the quality of concrete forming, affect the construction progress, consume manpower and materials, etc., and achieve good quality of appearance, reduce loss, and good forming effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The formwork erecting method for concrete pouring of floors and temporary roads of the present invention is suitable for concrete pouring with a thickness of ≤200mm, comprising the following steps:

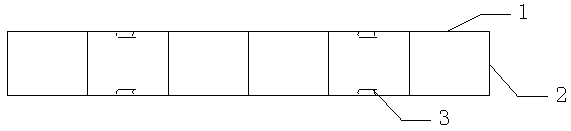

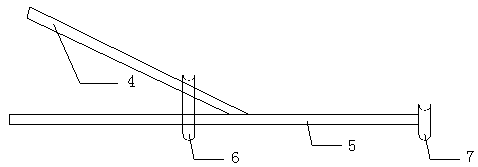

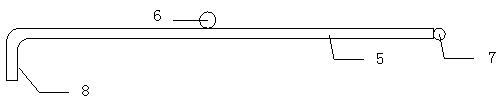

[0033] a. Make some special steel templates, please refer to figure 1 , figure 1 It is a structural schematic diagram of the steel formwork of the embodiment of the present invention. As shown in the figure, the steel formwork 1 is a rectangular formwork made of a steel plate with a length of 1500 mm and a width of 200 mm. The upper and lower ends of the rectangular formwork are solidly welded with two parallel transverse ribs, and several vertical ribs are arranged between the transverse ribs. , to enhance the strength of the rectangular formwork; a pair of first steel pipes 3 are provided at both ends of the rectangular formwork, the first steel pipes have an inner diameter of 20 mm and a length of 50 mm, and the pair of first steel pipes are radially symmetrically arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com