Underground coal seam gas pressure testing and hole sealing device and method

A sealing device and gas pressure technology, applied in gas discharge, safety devices, measurement, etc., to achieve the effects of stabilizing the surrounding rock of the drilling hole, flexible measurement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

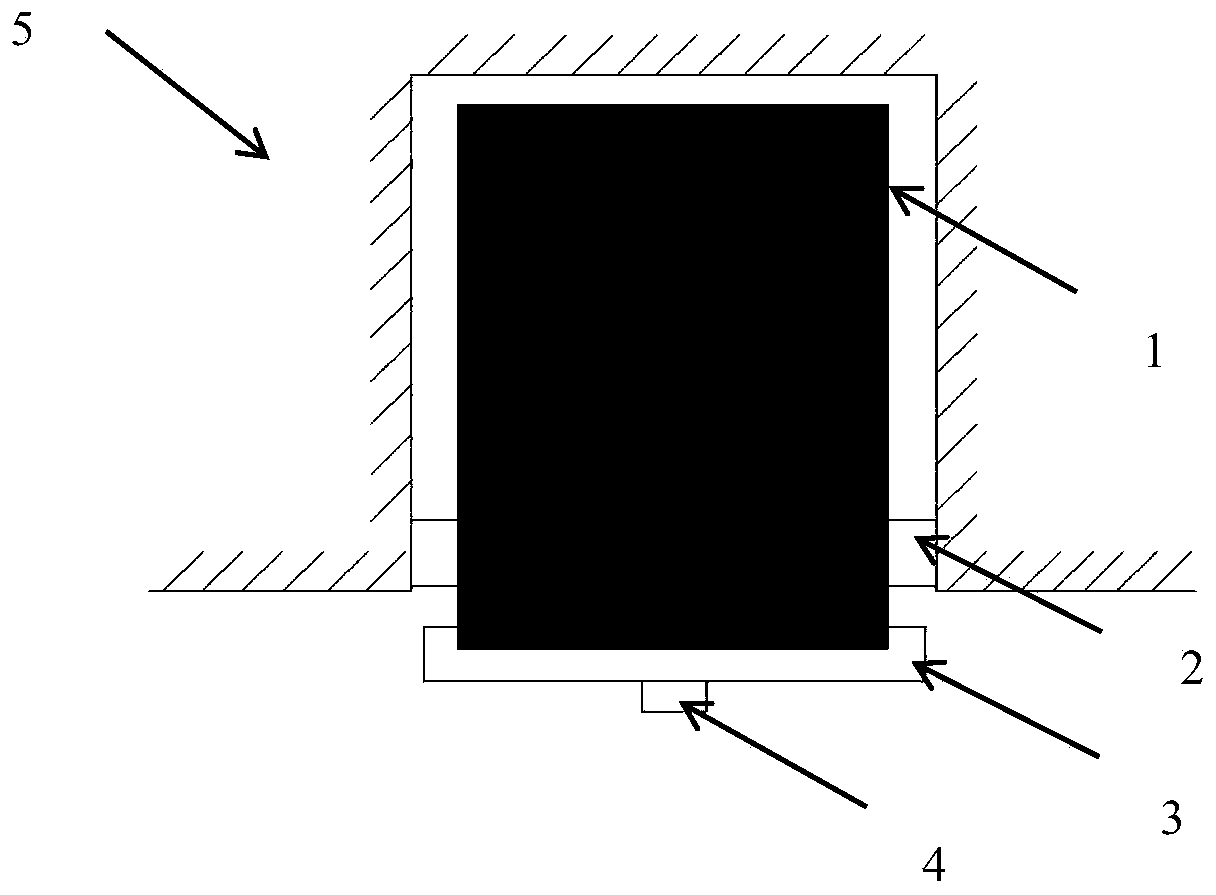

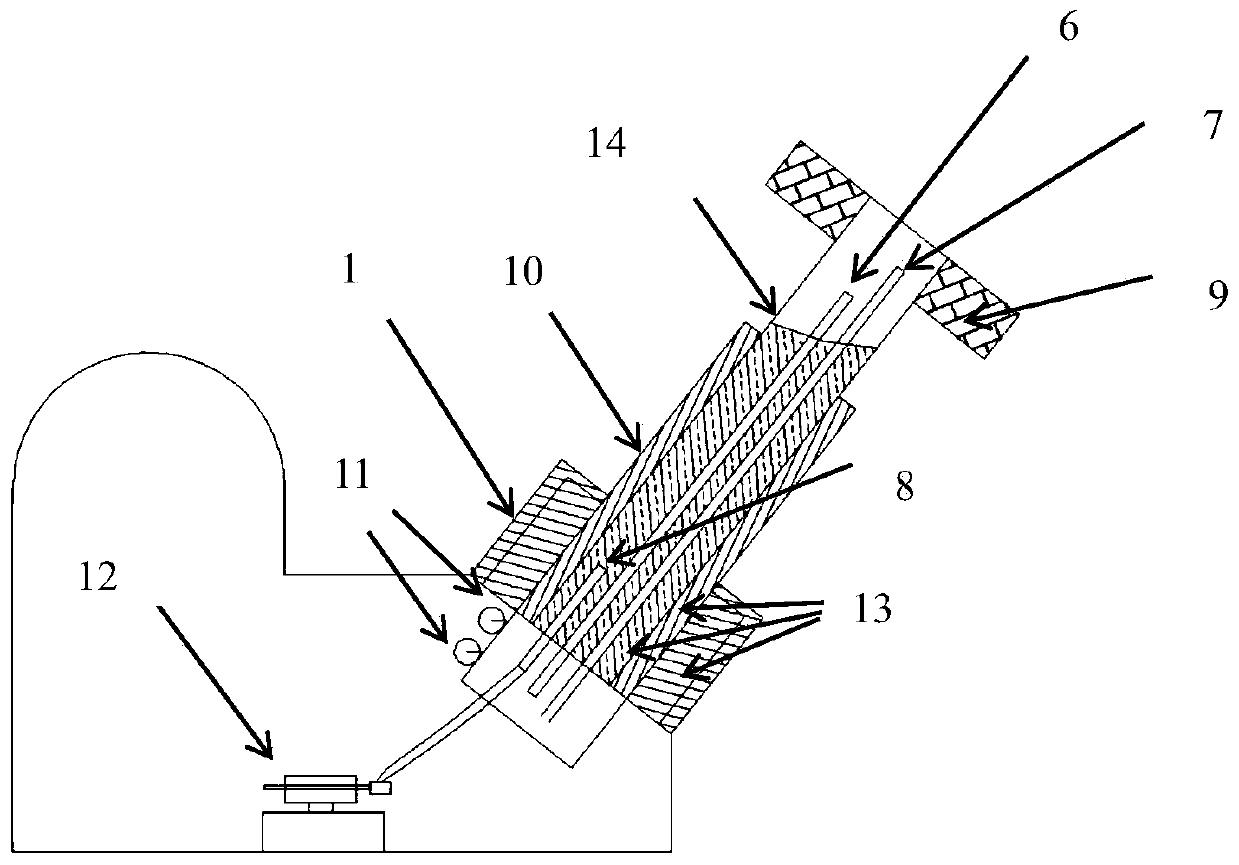

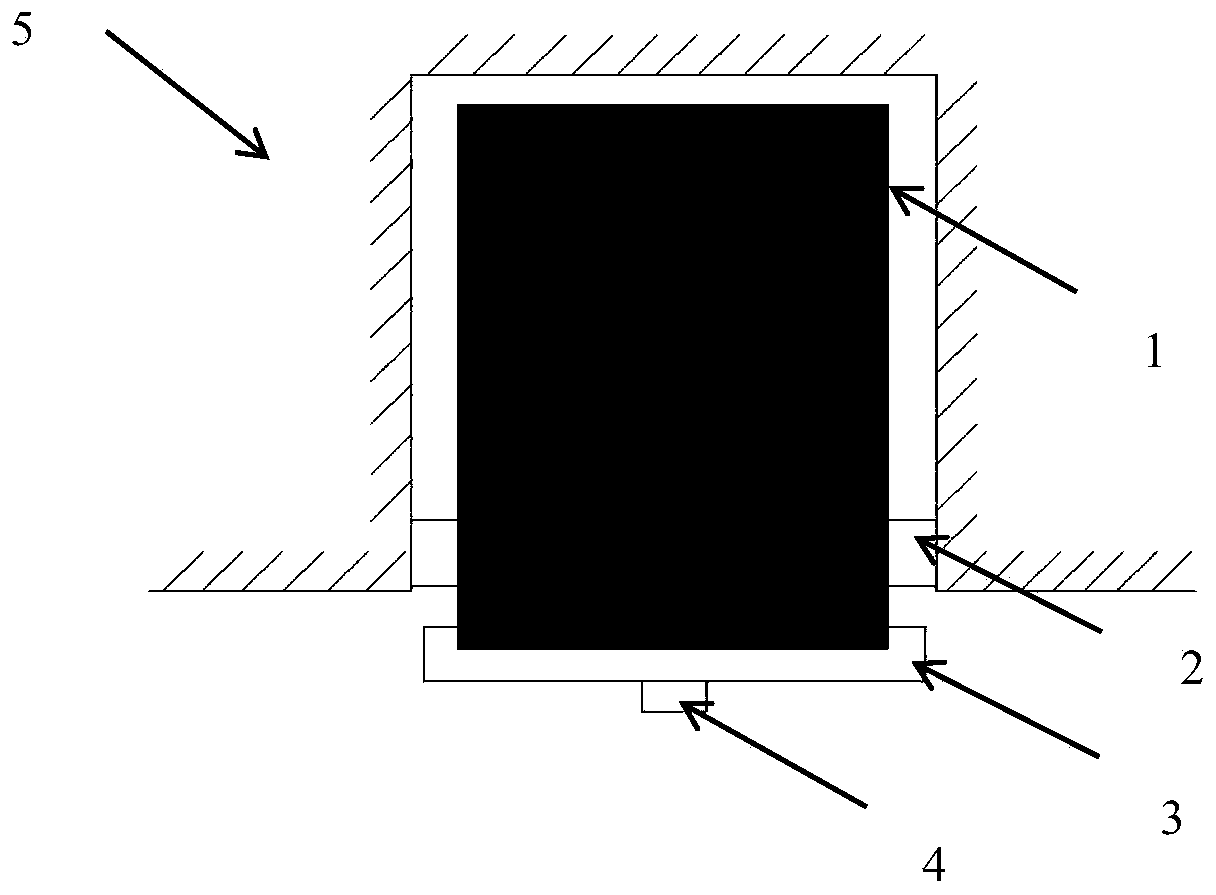

[0017] A gas pressure sealing device and method for underground coal seam testing of the present invention consists of an orifice pipe A (1), a wooden wedge (2), a flange (3), a grouting interface (4), and a grout return pipe (6 ), pressure measuring tube (7), grouting tube (8), orifice tube B (10), pressure gauge (11), grouting pump (12), cement mortar liquid (13), cylindrical borehole (14 )composition.

[0018] In the coal mine underground coal seam gas pressure test sealing device and method of the present invention, the specific operation steps are as follows:

[0019] a. Use a 130mm drill bit to drill 2m from the opening point and drill into the orifice pipe A (1);

[0020] b. Configure cement mortar (13), cooperate with wooden wedge (2) to fill the gap between the hole wall and fix the orifice pipe A (1);

[0021] c. After solidification between the orifice pipe A ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap