Bolt and nut connecting structure for dumbbell-like shaped symmetrical two-way tapered threads

A technology of tapered thread and connection structure, applied in the direction of connection components, nuts, bolts, etc., can solve the problems of poor self-locking, poor compatibility, and low connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

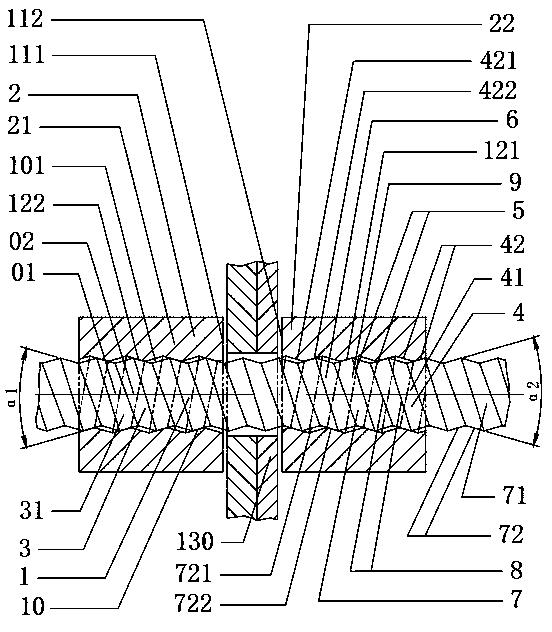

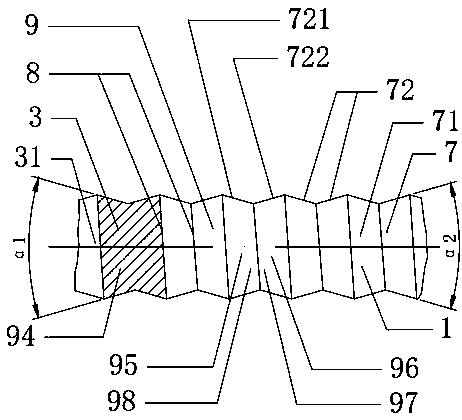

[0054] Such as figure 1 , figure 2 , image 3 As shown, the present embodiment adopts a bolt-to-double-nut connection structure, and the conical thread connection pair 10 of the bolt-to-nut connection structure of the bidirectional tapered thread includes a bidirectional frustum of cone 71 that is spirally distributed on the outer surface of the columnar matrix 3 and the bidirectional tapered hole 41 that is spirally distributed on the inner surface of the cylindrical mother body 2, that is, includes the external thread 9 and the internal thread 6 that are threaded with each other, and the internal thread 6 is distributed with a spiral bidirectional tapered hole 41 and The form of "non-solid space" exists, and the distribution of the external thread 9 is a helical bidirectional frustum of cone 71 and exists in the form of "material entity". The internal thread 6 and the external thread 9 are the relationship between the containing part and the contained part: internal The ...

Embodiment 2

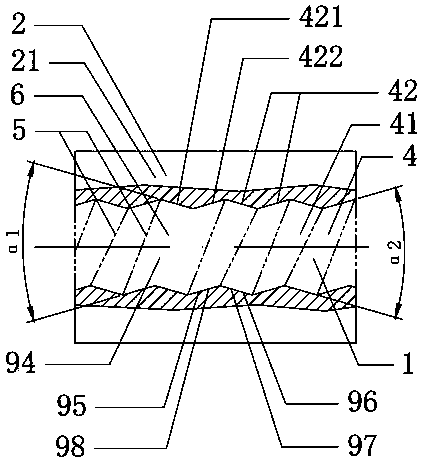

[0073] Such as Figure 4 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that this embodiment adopts a bolt-to-single-nut connection structure and the bolt body has a hexagonal head larger than the screw body 31, when The hexagonal head of the bolt is on the left side, and the cylindrical parent body 2, that is, the nut body 21, that is, the single nut is located on the right side of the workpiece 130 to be fastened. The relationship between 130 is also a rigid connection, and the rigid connection refers to that the end surface of the nut body 21 and the end surface of the workpiece 130 are mutually bearing surfaces, and the bearing surface is the locking bearing surface 111, and the workpiece 130 is Refers to the connected objects including the workpiece 130 .

[0074] The threaded work supporting surface of the present embodiment is a tapered threaded supporting surface 122, that is, the ...

Embodiment 3

[0077] Such as Figure 5 As shown, the structure, principle and implementation steps of this embodiment are similar to the first embodiment, the difference is that the positional relationship between the double nut and the fastened workpiece 130 is different, and the double nut includes a nut body 21 and a nut body 22 And the bolt body has a hexagonal head larger than the screw body 31. When the hexagonal head of the bolt is on the left side, the nut body 21 and the nut body 22 are all located on the right side of the fastened workpiece 130. The bolt and double nut connection structure of this embodiment During work, the relationship between the nut body 21, the nut body 22 and the fastened workpiece 130 is a non-rigid connection, and the non-rigid connection refers to that the opposite side faces of the two nuts, namely the nut body 21 and the nut body 22, support each other. The support surface includes a locking support surface 111 and a locking support surface 112, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com