Plate detecting device

A detection device and plate technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of large influence of subjective factors, different measurement results, damage to tile embryos, etc., to ensure production efficiency and production quality. The effect of compact structure and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

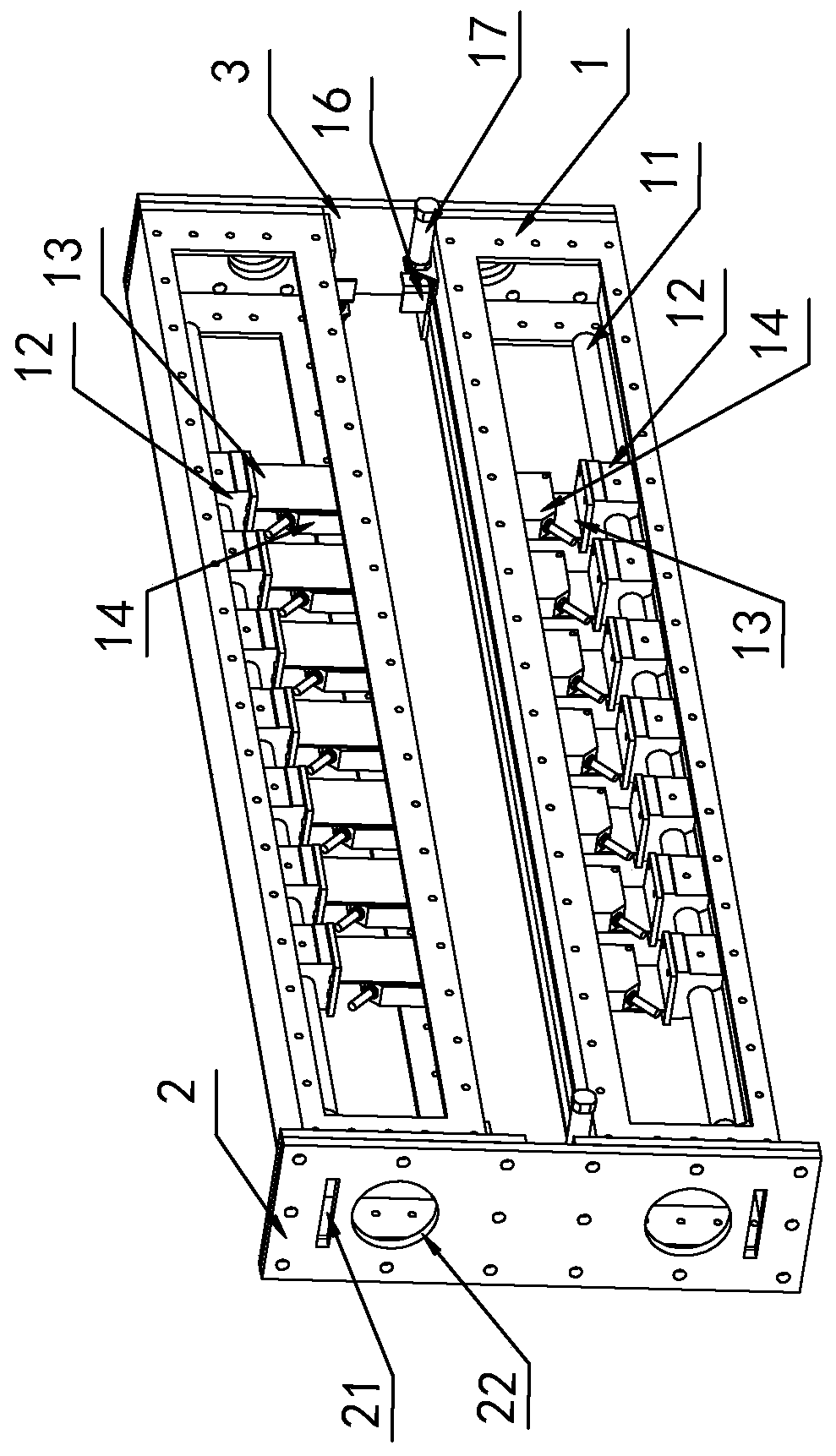

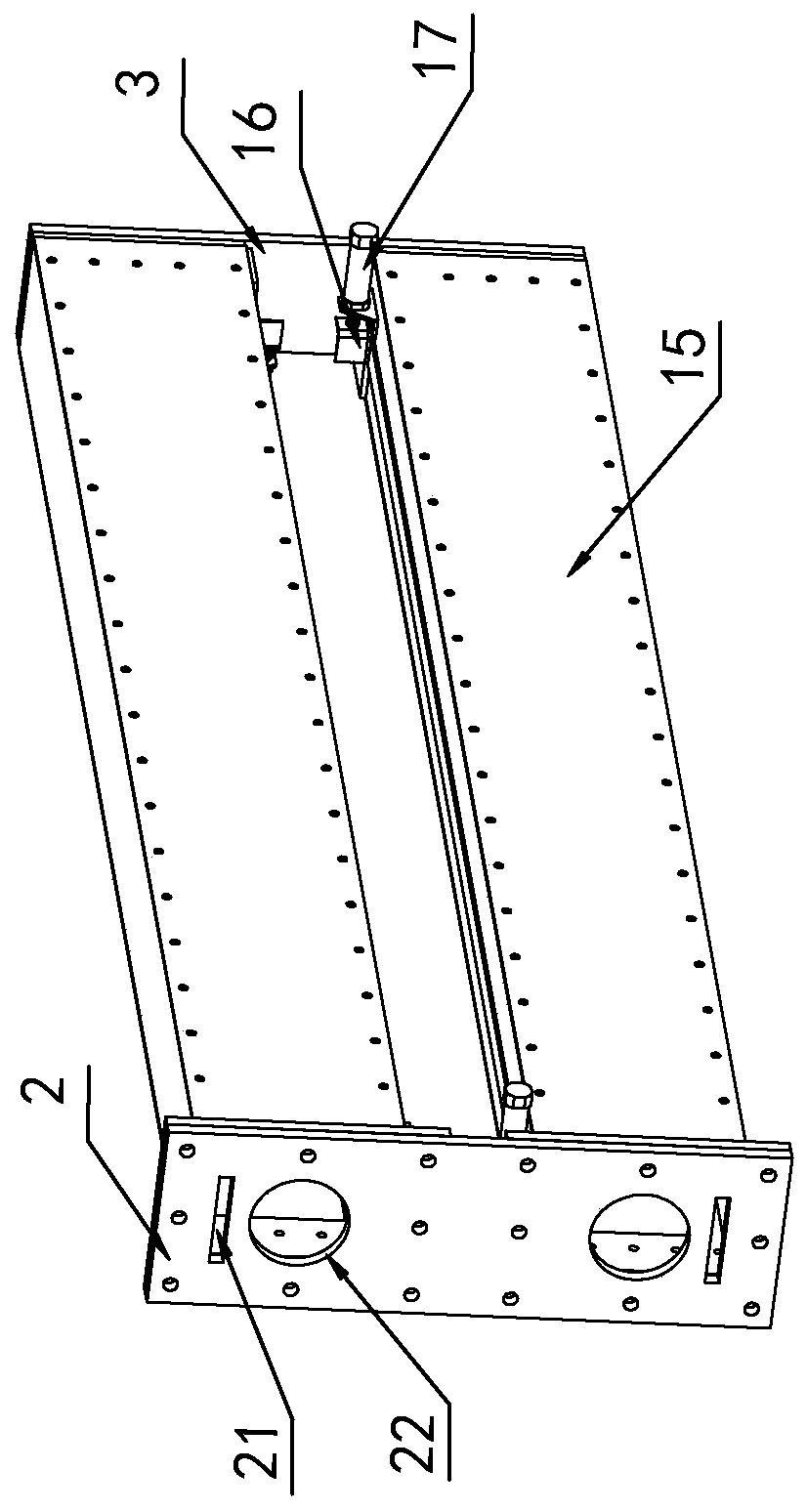

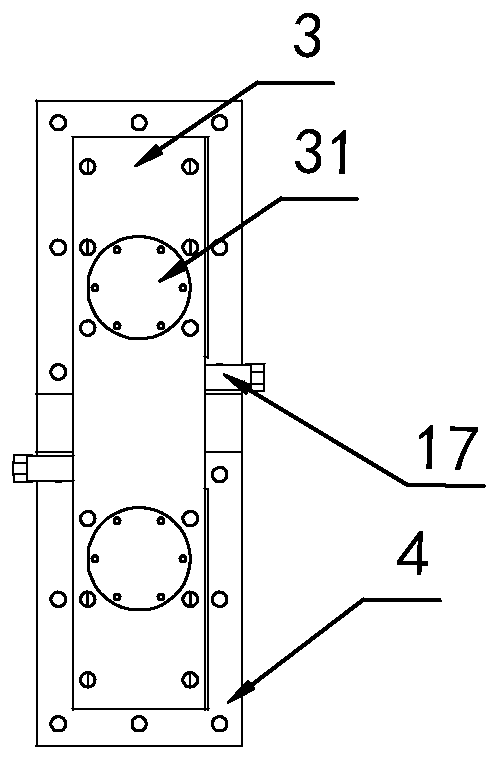

[0026] refer to Figure 1 to Figure 9 , the present invention is a plate detection device, including a detection group. The detection group includes two detection assemblies, and several displacement sensors 14 are arranged in both detection assemblies. The detection assembly is usually provided with a bracket or housing 1 for fixing the displacement sensor 14, and the displacement sensor 14 can be set to be completely fixed or adjustable in position. There is a gap passing through the plate between the two detection components. Generally, the detection components are elongated and arranged parallel to each other. The width and length of the gap should be correspondingly greater than the thickness and width of the measured plate. The displacement sensors 14 in the two detection assemblies all face the gap between the two detection assemblies. The displacement sensors 14 in different detection assemblies correspond to each other, that is, the displacement sensors 14 exist in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com