Composition for antireflection film, antireflection film formed therefrom, polarizing plate comprising same, and optical display device comprising same

An anti-reflection film and composition technology, applied in optics, optical elements, nonlinear optics, etc., can solve the problems of reducing the reflectivity of the anti-reflection film, the complexity of the anti-reflection film, and the reduction of the reflectivity of the anti-reflection film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

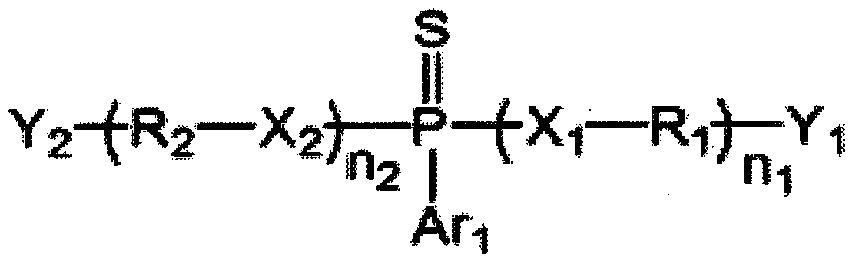

[0117] Preparation Example 1: Preparation of Formula 1a

[0118] (1) Prepare a solution by diluting 2.11g (10mmol) phenylenephosphonothiodichloride in 30mL tetrahydrofuran (THF), cool the solution to 0°C with an ice bath, and then add 1.14g (11mmol) triethyl Amine solution. Next, a solution was prepared by diluting 1.1 g (10 mmol) of thiophenol in 10 mL of THF, and this solution was slowly added to the resulting solution using a dropping funnel. Keep the resulting solution at 0°C, add 1.14 g (11 mmol) triethylamine to the resulting solution, and slowly add 1.25 g (10 mmol) of 4-aminobenzenethiol in 6 mL of THF using a dropping funnel Solutions prepared by dilution. After the addition was complete, the ice bath was removed and the resulting solution was stirred for about 2 hours. After the reaction was completed, the resulting solution was filtered to remove the amine salt, and then the excess solvent was distilled off under reduced pressure. Then, 100 mL of ethyl acetate (...

preparation Embodiment 2

[0124] Preparation Example 2: Preparation of Formula 1b

[0125] (1) A compound represented by formula B was prepared by the same method as in Preparation Example 1 except that 1.26 g (10 mmol) of 4-hydroxybenzenethiol was used instead of 4-aminobenzenethiol. by column chromatography (SiO 2 , ethyl acetate:hexane=1:4) isolated the final compound {colorless oil, yield: 72%, refractive index: 1.69, 1 H-NMR (300MHz, CDCl 3 ): δ7.99-7.91 (m, 2H), 7.52-7.35 (m, 6H), 7.31-7.23 (m, 5H), 6.74 (dd, J=1.5, 6.6Hz, 2H)}.

[0126] [Formula B]

[0127]

[0128] (2) The compound represented by Formula 1b was prepared by the same method as in Preparation Example 1 except that 2.19 g (5.8 mmol) of the compound represented by Formula B was used instead of the compound represented by Formula A. by column chromatography (SiO 2 , ethyl acetate: hexane = 1:5) isolated the final compound {colorless oil, yield: 78%, refractive index: 1.685, 1 H-NMR (300MHz, CDCl 3 ):δ8.00-7.92(m,2H),7.53-7....

preparation Embodiment 3

[0131] Preparation Example 3: Preparation of Formula 1c

[0132] A solution prepared by diluting 25.04 g (200 mmol) of 4-aminobenzenethiol in 400 mL of THF was cooled to 0° C. using an ice bath, and then 21.3 g (210 mmol) of triethylamine was added. The resulting solution was kept at 0° C., and 21.1 g (100 mmol) of phenylenephosphonothiodichloride was diluted in 200 mL of THF to prepare a solution, which was slowly added to the resulting solution using a dropping funnel. After the addition was complete, the ice bath was removed and the resulting solution was stirred for about 2 hours. After the reaction was completed, the resulting solution was filtered to remove the amine salt, and cooled to 0° C., and then 21.3 g (210 mmol) of triethylamine was added to the resulting solution. Then, a solution prepared by diluting 18.6 g (205 mmol) of acryloyl chloride in 100 mL of THF was slowly added to the resulting solution, followed by stirring at 0° C. for 1 hour. After the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com