Film forming device

A film-forming device and film-forming area technology, applied in transportation and packaging, furnace, charge manipulation, etc., can solve difficult film-forming problems, and achieve the effects of preventing pollution, reducing waste, and reducing the amount of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0045] figure 1 It is a schematic configuration diagram showing the whole of an embodiment of the film forming apparatus of the present invention.

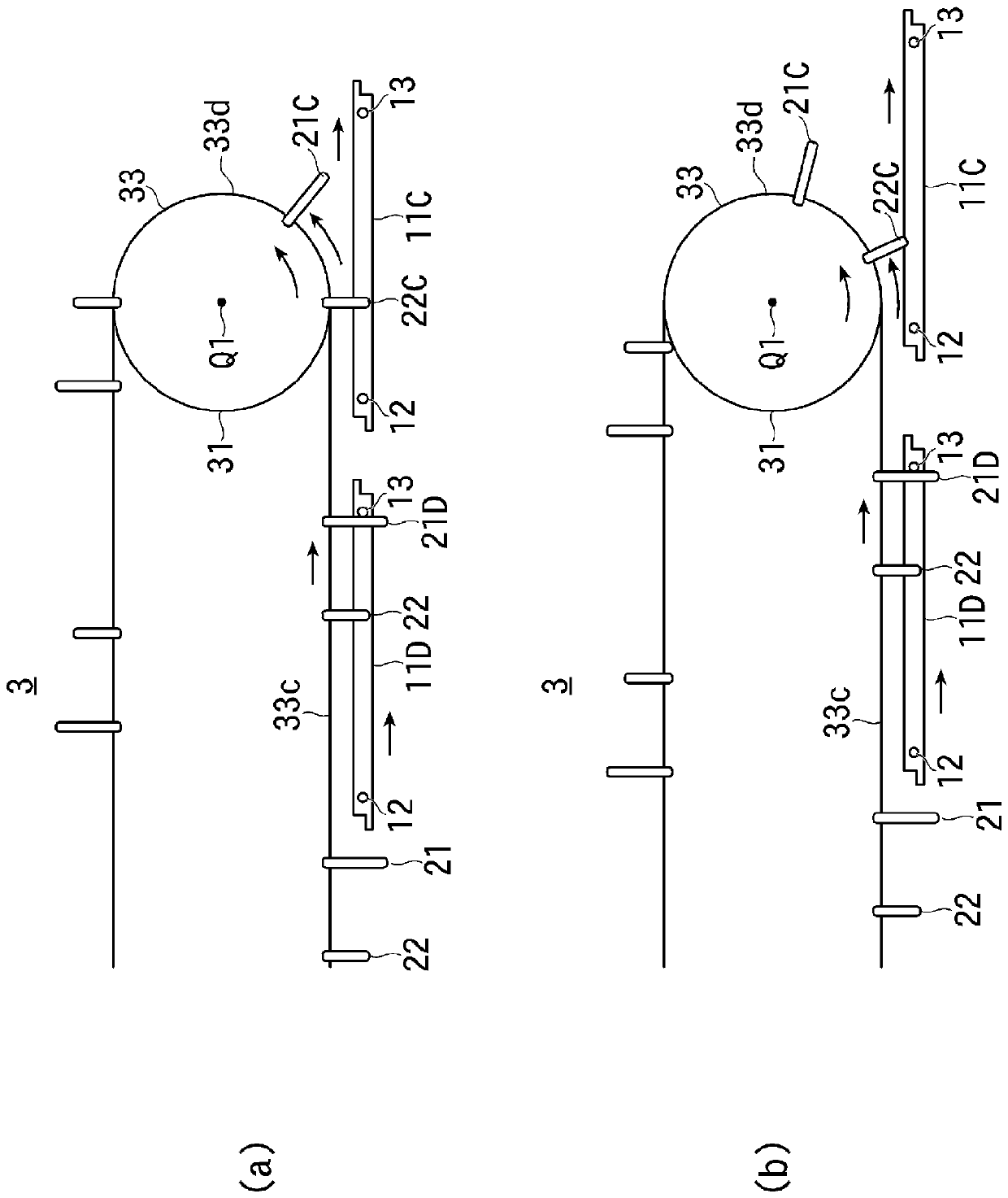

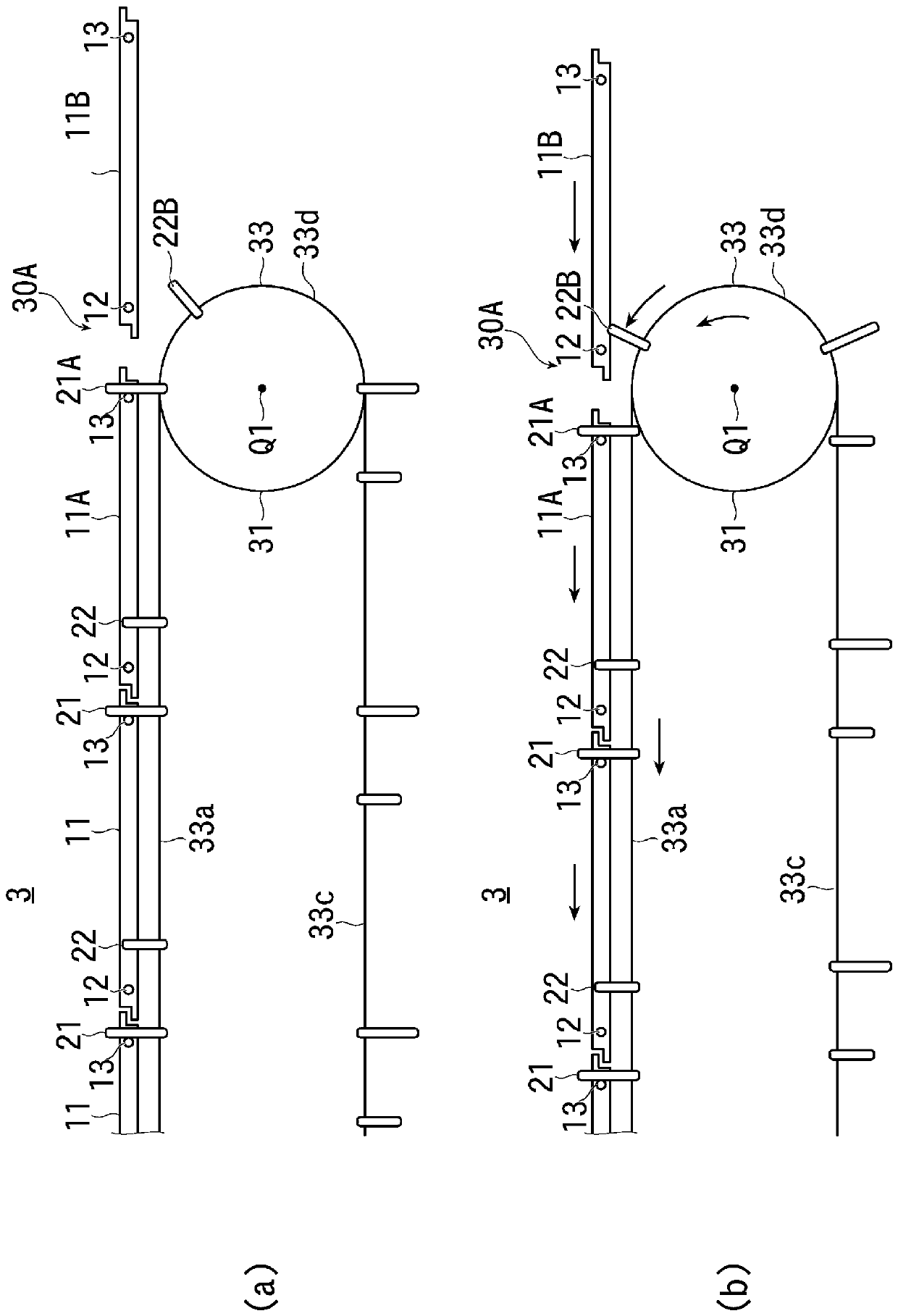

[0046] also, figure 2 is a plan view showing the basic structure of the substrate holder transport mechanism of this embodiment, image 3 It is a front view showing the main part structure of this board|substrate holder conveyance mechanism.

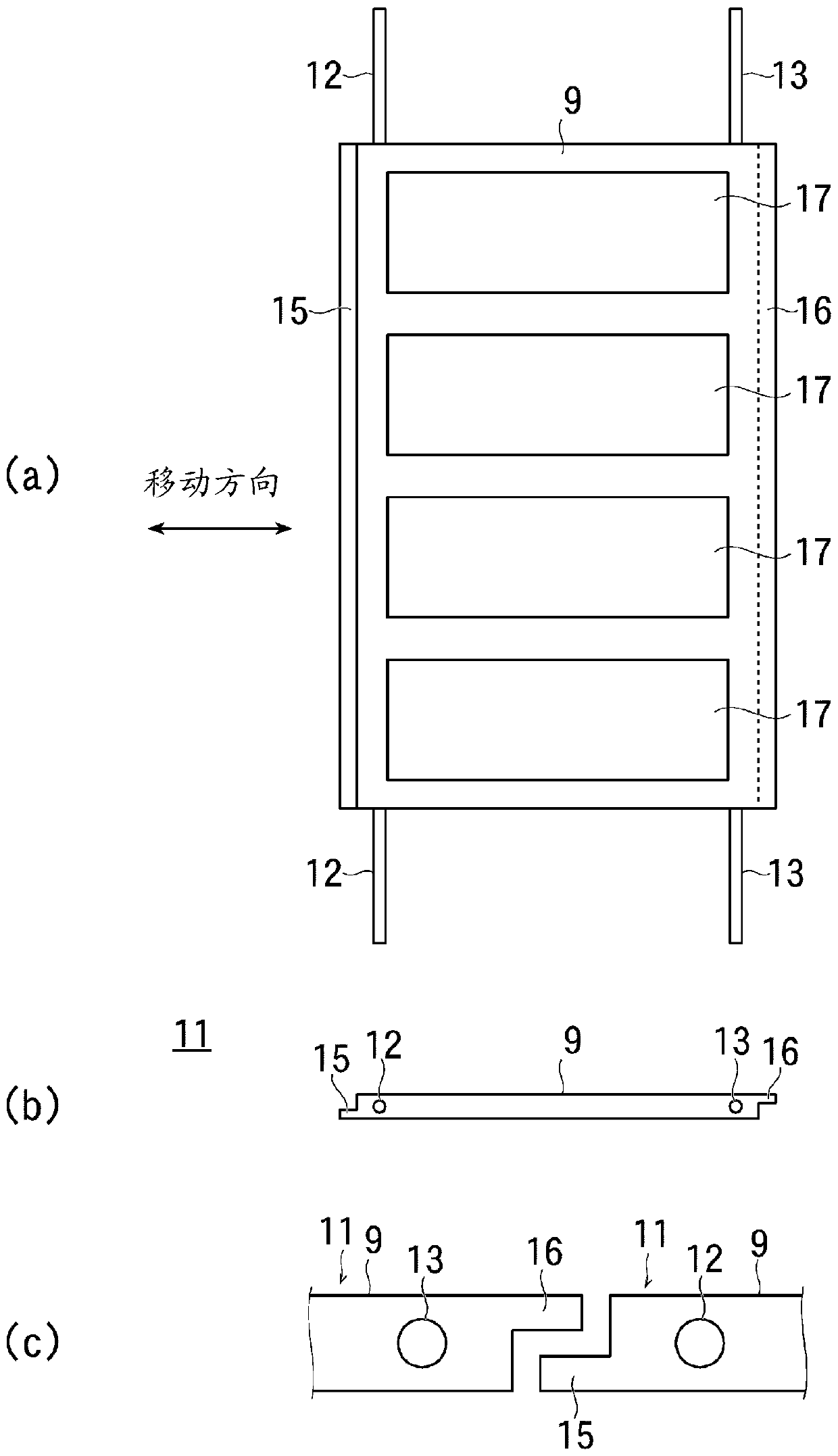

[0047] and then, Figure 4 (a)~ Figure 4 (c) shows the structure of the substrate holder used in this embodiment, Figure 4 (a) is a plan view, Figure 4 (b) is the front view, Figure 4 (c) is an enlarged view showing the vicinity of the shielding portion.

[0048] Such as figure 1 As shown, the film formation apparatus 1 of this embodiment has the vacuum chamber 2 which forms a single vacuum atmosphere connected to the vacuum exhaust apparatus 1a.

[0049] A co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com