Vacuum deposition device

An evaporation and vacuum technology, which is applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem of weak directivity of evaporated materials and failure of evaporated materials to reach film-forming objects and evaporated materials Problems such as poor adhesion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

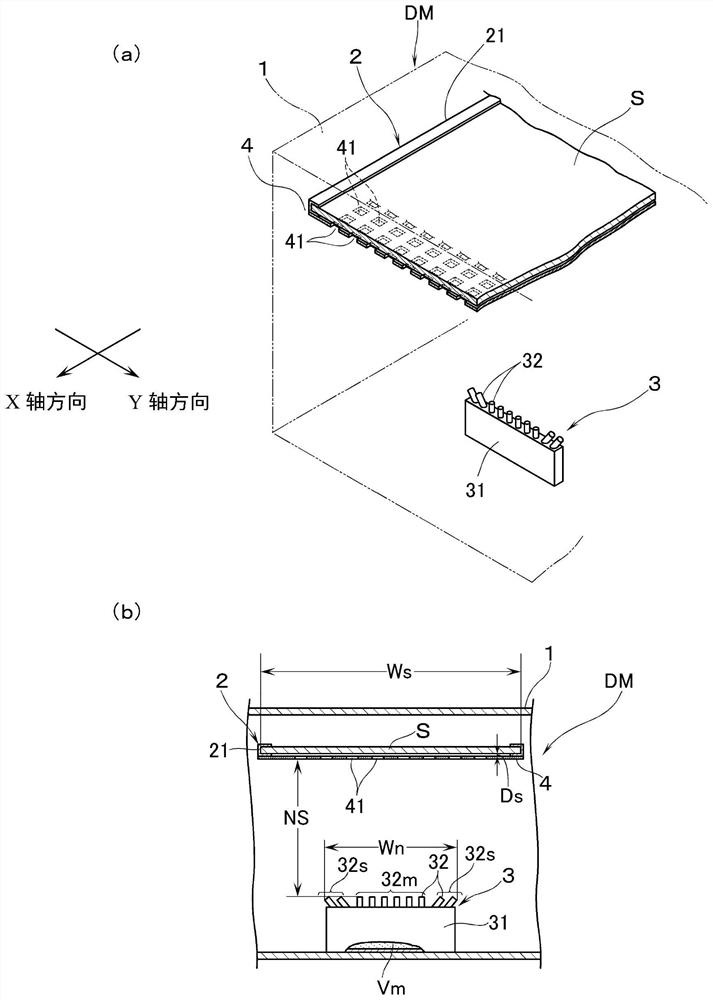

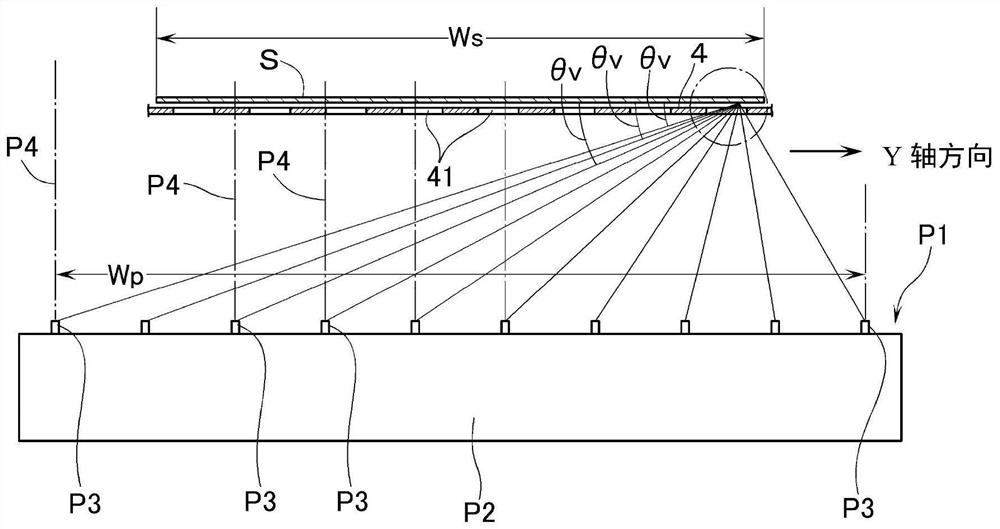

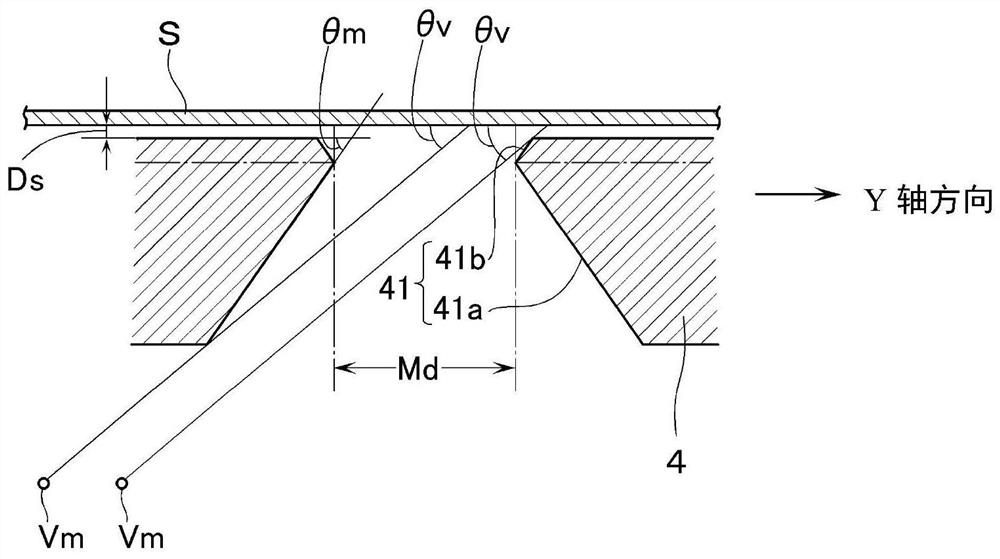

[0021] Referring to the accompanying drawings, a glass substrate with a predetermined thickness having a rectangular outline is used as the object to be filmed (hereinafter referred to as "substrate S"), and a case where a predetermined thin film is formed on one side of the substrate S is taken as an example to illustrate the vacuum evaporation method of the present invention. Embodiment of the plating apparatus. Hereinafter, terms indicating directions such as up and down are figure 1 Describe the basis.

[0022] refer to figure 1 (a) and (b), the vacuum evaporation device DM has a vacuum chamber 1 . Although not particularly illustrated, a vacuum pump is connected to the vacuum chamber 1 through an exhaust pipe, and it can be evacuated to a predetermined pressure (vacuum degree) and maintained. Furthermore, a substrate transfer device 2 is provided on the upper portion of the vacuum chamber 1 . The substrate conveying device 2 has a conveyer 21 that holds the substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com