A kind of anti-twist embedded automobile shock absorber hydraulic disassembly equipment

An automotive shock absorber, embedded technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., to achieve the best performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

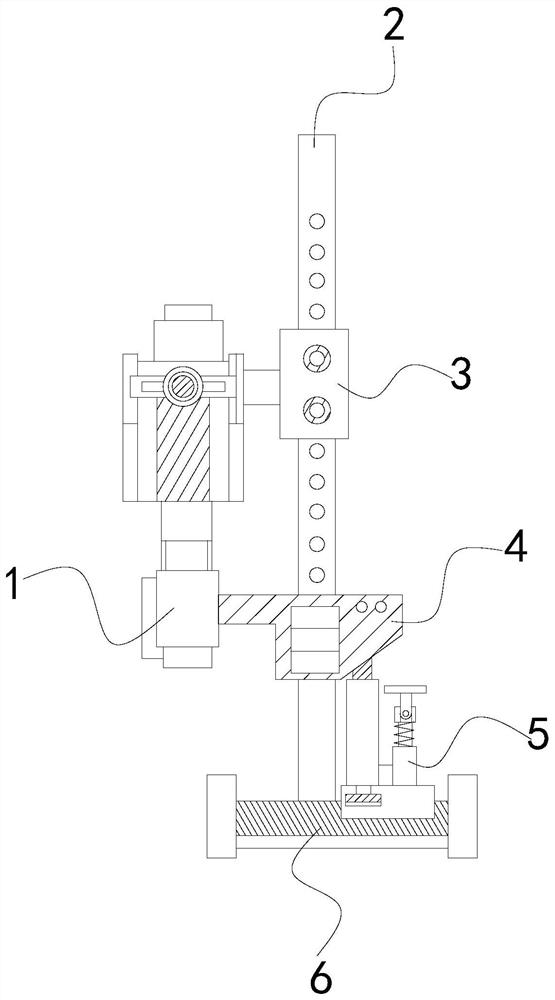

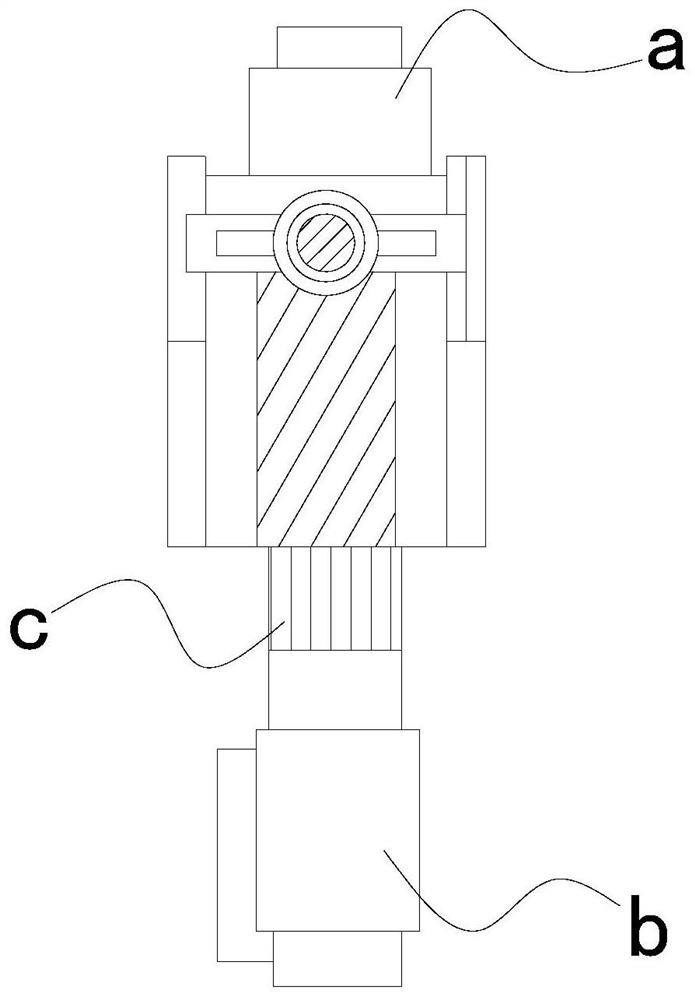

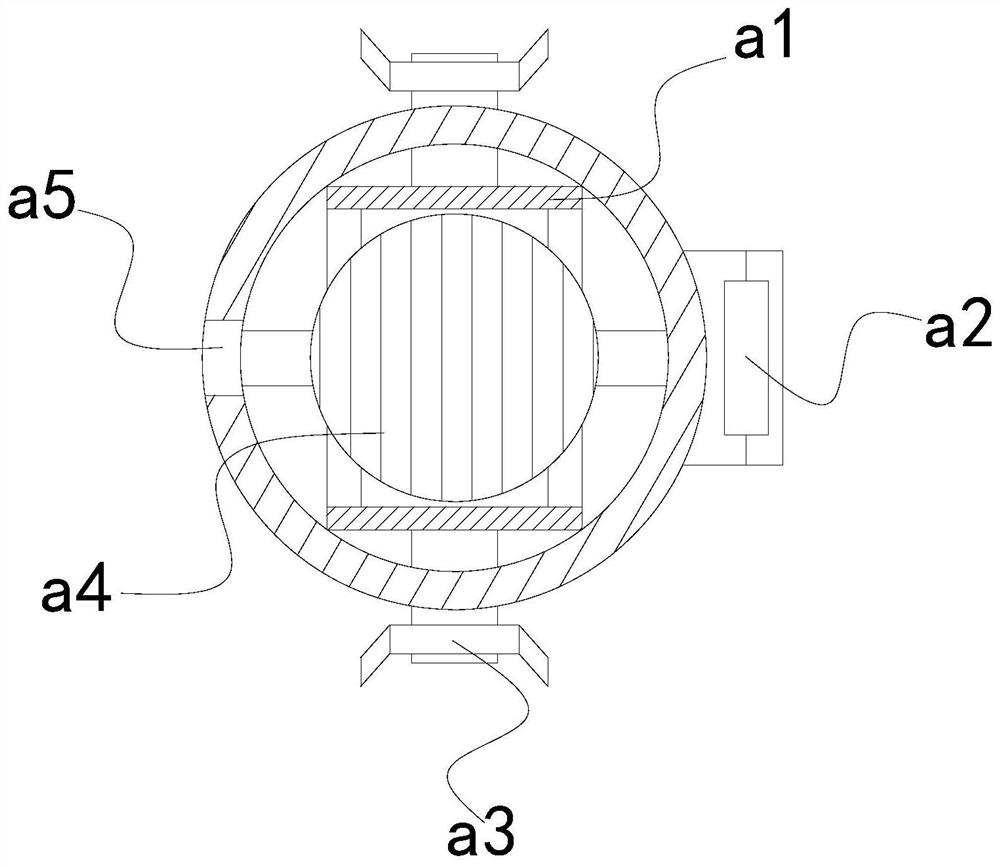

[0024] See Figure 1-Figure 6 , The present invention provides a technical solution for anti-twisting embedded hydraulic disassembly and assembly equipment for automobile shock absorbers: its structure includes: anti-twist body 1, hole slot rod 2, assembly slider 3, hydraulic auxiliary clamp 4, hydraulic lifting device 5. Shock-absorbing base 6. The anti-twist body 1 is provided with an assembly slider 3 on the upper right side and locked with the assembly slider 3, and the anti-twist body 1 is provided with a hydraulic auxiliary holder 4 at the lower left, and the hydraulic auxiliary The clamping seat 4 is buckled with the anti-twist body 1, the assembly sliding block 3 and the hydraulic auxiliary clamping seat 4 are inserted through the outer side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com