Rapid-hardening early strength concrete prepared from various industrial solid wastes, and preparation method thereof

A technology for solid waste and concrete, which is applied in the field of alkali-excited cementitious materials, can solve the problems of not obtaining high added value/high dosage, and it is difficult to take into account the work performance, mechanical performance and shrinkage performance, so as to improve the utilization value, The effect of improving work performance, energy consumption and reducing energy consumption in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

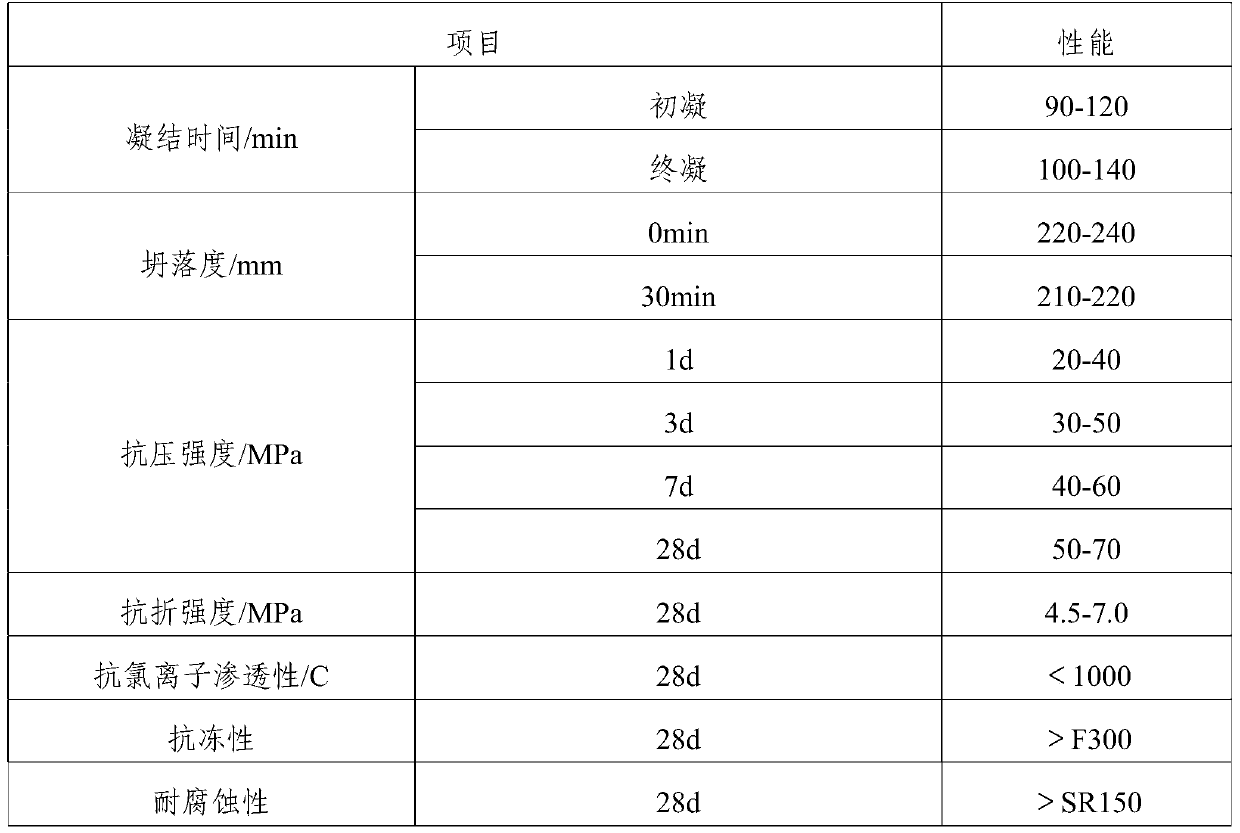

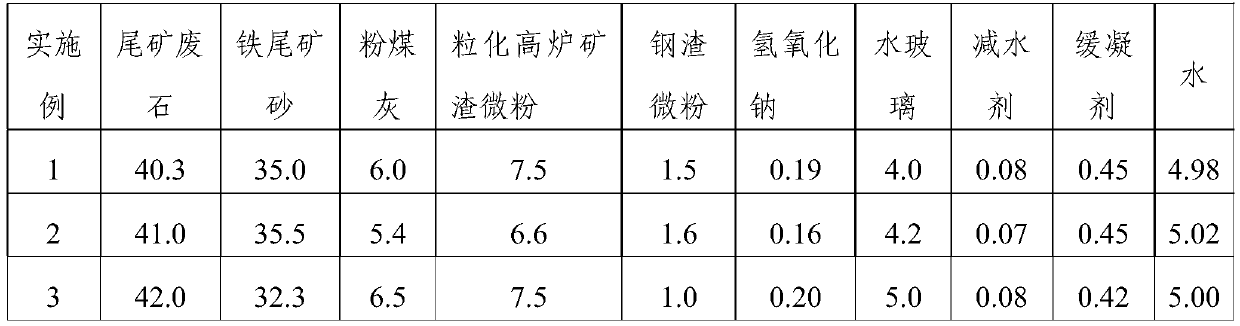

[0050] The rapid-hardening and early-strength concrete was prepared by using bulk industrial solid waste tailings waste rock, iron tailings sand, fly ash, granulated blast furnace slag powder, and steel slag powder. The ratio of each component is shown in Table 2.

[0051] Table 2 Rapid-hardening and early-strength concrete mix ratio / %

[0052]

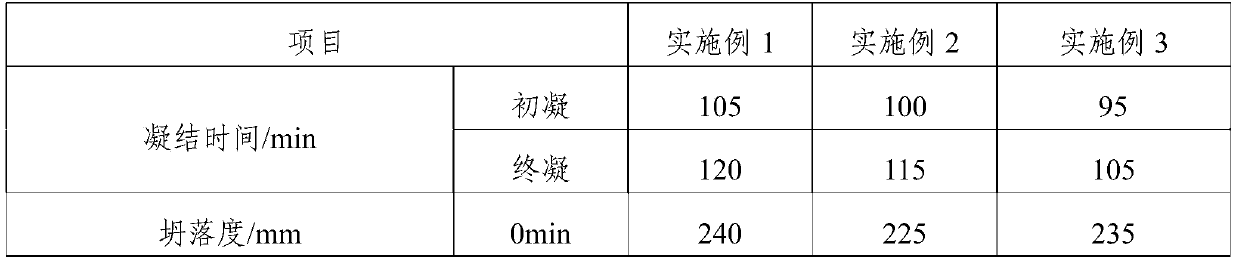

[0053] Sodium hydroxide is first prepared as a saturated solution and then mixed with water glass, retarder, water reducer and water in a certain proportion at a low speed for 2 minutes to prepare a liquid material; then tailing waste rock, iron tailing sand, fly ash particles The blast furnace slag micropowder and steel slag micropowder are mixed according to a certain proportion for 1 minute to prepare a solid material; finally, a certain proportion of liquid material is added, and the solid material and liquid material are mixed for 2 minutes to prepare a rapid-hardening early-strength concrete, and its properties are shown in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com