Binder for amorphous basic refractory material, and preparation technology thereof

A technology of refractory materials and binders, applied in the field of binders for amorphous basic refractory materials and its preparation, can solve the problems of large influence of water addition on construction performance, reduced thermal shock resistance, slow strength development, etc., and achieve improvement Effects of thermal shock resistance and erosion resistance, improvement of construction performance and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

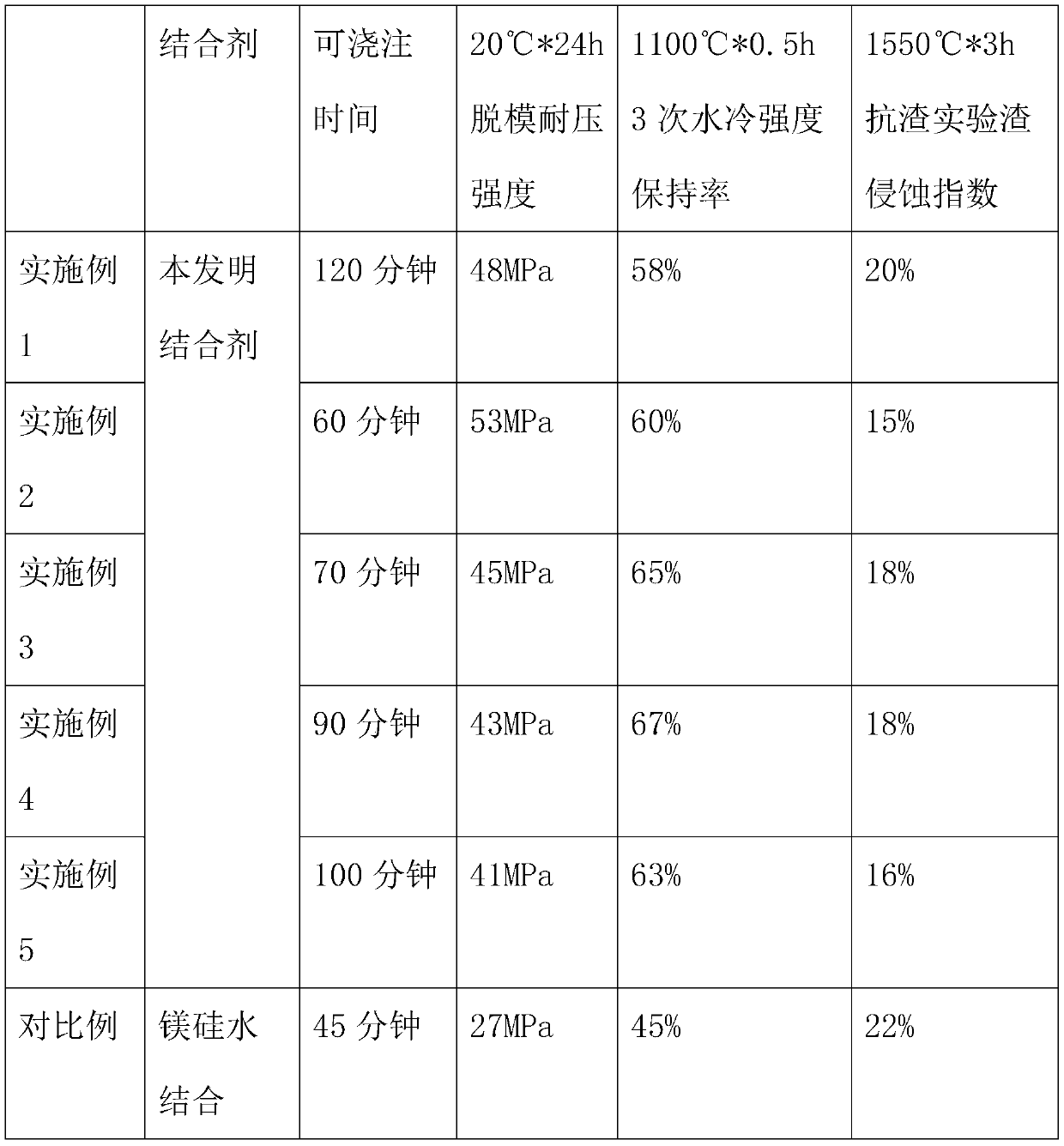

Examples

Embodiment 1

[0021] The present invention proposes a binder for amorphous basic refractory materials, whose raw materials are formulated as follows by weight: 100 parts of magnesium-based powder, 20 parts of silicon dioxide powder, and 0.1 part of activator.

[0022] The formulation by weight of the activator is as follows: 30 parts of polycarboxylic acid, 20 parts of benzenesulfonate, 5 parts of metasilicate, and 5 parts of organic weak acid.

[0023] The magnesium-based powder is specifically a powder with a magnesium oxide content>95%. The magnesium-based powder is one or a mixture of magnesium oxide fine powder and lightly burned magnesia fine powder. The magnesium-based powder and The particle size of silica powder should be less than 8mm.

[0024] The present invention also provides a preparation process of a binder for amorphous basic refractories, comprising the following steps:

[0025] S1. Select the ball mill as an auxiliary tool, and clean the inside of the ball mill several t...

Embodiment 2

[0028] The present invention proposes a binder for amorphous basic refractory materials, whose raw materials are formulated as follows by weight: 200 parts of magnesium-based powder, 40 parts of silicon dioxide powder, and 1 part of activator.

[0029] The formulation by weight of the activator is as follows: 40 parts of polycarboxylic acid, 30 parts of benzenesulfonate, 8 parts of metasilicate, and 8 parts of organic weak acid.

[0030] The magnesium-based powder is specifically a powder with a magnesium oxide content>95%. The magnesium-based powder is one or a mixture of magnesium oxide fine powder and lightly burned magnesia fine powder. The magnesium-based powder and The particle size of silica powder should be less than 8mm.

[0031] The present invention also provides a preparation process of a binder for amorphous basic refractories, comprising the following steps:

[0032] S1. Select the ball mill as an auxiliary tool, and clean the inside of the ball mill several tim...

Embodiment 3

[0035] The present invention proposes a binder for amorphous basic refractory materials, whose raw materials are formulated as follows by weight: 300 parts of magnesium-based powder, 45 parts of silicon dioxide powder, and 1.5 parts of activator.

[0036] The formulation by weight of the activator is as follows: 45 parts of polycarboxylic acid, 35 parts of benzenesulfonate, 10 parts of metasilicate, and 10 parts of organic weak acid.

[0037] The magnesium-based powder is specifically a powder with a magnesium oxide content>95%. The magnesium-based powder is one or a mixture of magnesium oxide fine powder and lightly burned magnesia fine powder. The magnesium-based powder and The particle size of silica powder should be less than 8mm.

[0038] The present invention also provides a preparation process of a binder for amorphous basic refractories, comprising the following steps:

[0039] S1. Select the ball mill as an auxiliary tool, and clean the inside of the ball mill severa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap