Sulfhydryl castor oil-based deep photocuring material and preparation method and application thereof

A light-curing material, castor oil-based technology, applied in the field of bio-based UV curable materials, can solve the problem of low light-curing activity of vegetable oil double bonds, and achieve the effect of overcoming the phenomenon of oxygen inhibition, uniform polymerization network, and delayed gel point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

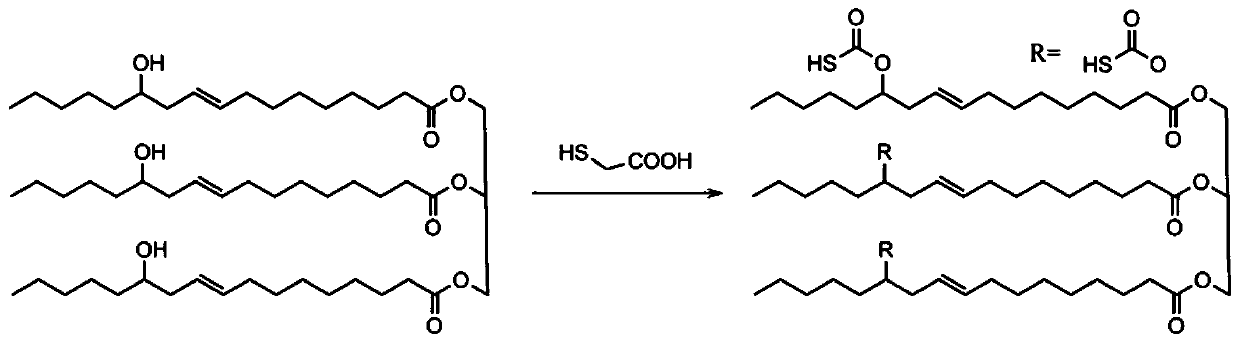

Method used

Image

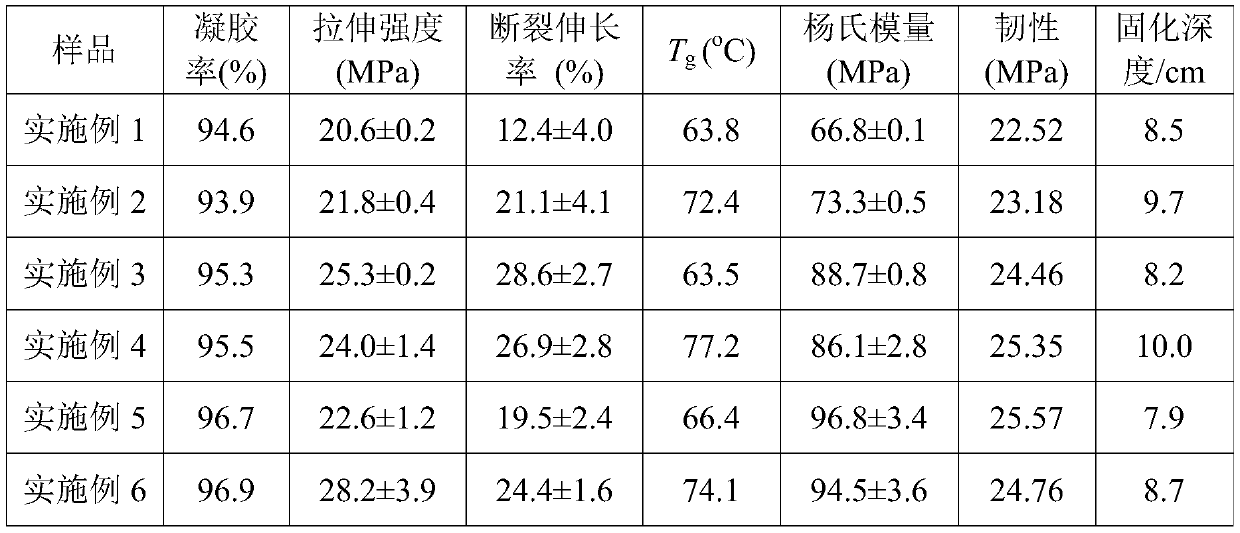

Examples

Embodiment 1

[0028] (1) Add castor oil, p-toluenesulfonic acid and cyclohexane in sequence in the reactor, then install the water separator, stir evenly, heat up to 120°C, add mercaptoacetic acid, react for 11 hours, pour the reaction solution into the separator In the liquid funnel, add water to wash to remove excess thioglycolic acid, add cyclohexane to static layer, take the upper layer in a three-necked flask, add anhydrous magnesium sulfate to dry, and finally distill at 70°C under reduced pressure to obtain mercapto castor oil. Wherein, the molar ratio of castor oil and thioglycolic acid is 1:5, the consumption of p-toluenesulfonic acid is 6% of castor oil quality, and the cyclohexane consumption is 1g castor oil needs cyclohexane to be 4ml.

[0029] (2) Mix the mercapto castor oil and the photoinitiator 1173 uniformly under the condition of completely avoiding light, and the obtained prepolymer solution is the required mercapto castor oil-based deep photocurable material. Wherein, p...

Embodiment 2

[0032] (1) Add castor oil, p-toluenesulfonic acid and cyclohexane in sequence in the reactor, then install the water separator, stir evenly, heat up to 110°C, add 3-mercaptopropionic acid, react for 10h, and dissolve the reaction solution Pour into a separatory funnel, add water to wash to remove excess 3-mercaptopropionic acid, add cyclohexane to static layer, take the upper layer in a three-necked flask, add anhydrous magnesium sulfate to dry, and finally distill under reduced pressure at 65°C to obtain Mercapto castor oil. Wherein, the molar ratio of castor oil and 3-mercaptopropionic acid is 1:6, the consumption of catalyst p-toluenesulfonic acid is 5% of castor oil quality, and the cyclohexane consumption is 1g castor oil needs cyclohexane to be 5ml.

[0033] (2) Mix castor oil, mercapto castor oil and photoinitiator 184 uniformly under the condition of completely avoiding light, and the obtained prepolymer solution is the required mercapto-containing castor oil-based dee...

Embodiment 3

[0036] (1) Add castor oil, p-toluenesulfonic acid and cyclohexane in sequence in the reactor, then install the water separator, stir evenly, heat up to 110°C, add 2-mercaptobutyric acid, react for 9 hours, and dissolve the reaction solution Pour into a separatory funnel, add water to wash to remove excess 2-mercaptobutyric acid, add cyclohexane to static layer, take the upper layer in a three-necked flask, add anhydrous magnesium sulfate to dry, and finally distill under reduced pressure at 60°C to obtain Mercapto castor oil. Wherein, the molar ratio of castor oil and 2-mercaptobutyric acid is 1:7, the consumption of catalyst p-toluenesulfonic acid is 3% of castor oil quality, and the cyclohexane consumption is 1g castor oil needs cyclohexane to be 6ml.

[0037] (2) Mix castor oil, mercapto castor oil and photoinitiator 907 uniformly under the condition of completely avoiding light, and the obtained prepolymer solution is the desired mercapto-containing castor oil-based deep-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com