Multi-point-station automatic water spraying tin refining and crystallization device

A technology of crystallization device and water spray device, which is applied in the field of multi-point automatic water spray tin refining and crystallization device, which can solve the problems of product output, quality fluctuation, difficulty in achieving high quality, high output, low consumption, equipment level stay, etc., and achieve crystallization The effect is good, the on-site operation environment is improved, and the effect of material balance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

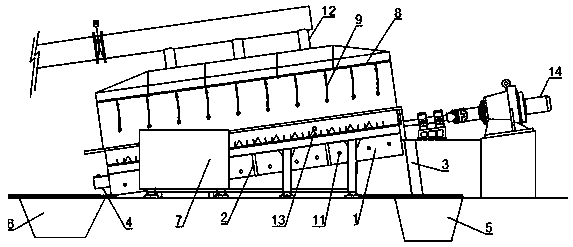

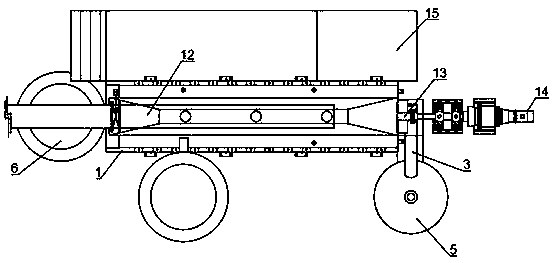

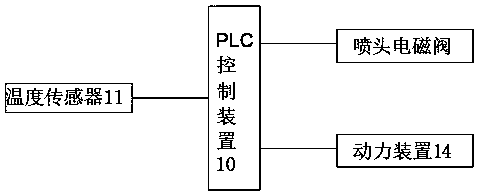

Method used

Image

Examples

Embodiment 1

[0030]When the continuous crystallizer starts to work, the heating device 2 is started first, and the temperature in the tank body 1 of the crystallizer is respectively set to five temperature zones: the first temperature zone is 180°C-185°C; the second-stage temperature zone is 190-200°C; The temperature zone of the first stage is 205~210℃; the temperature zone of the fourth zone is 21~-225℃; the temperature zone of the fifth zone is 230~240℃. The optimum temperature for each area is 183°C for the first stage; 195°C for the second stage; 207°C for the third stage; 219°C for the temperature region; and 232°C for the temperature region. Temperature is the main factor affecting the quality of refined tin and solder in the crystallizer. The temperature in the tank body 1 of the crystallization machine is set to five temperature zones respectively. When the crude tin enters the crystallizer, it is cooled by spraying water, so that the crude tin liquid rapidly drops from 230°C to b...

Embodiment 2

[0034] When the continuous crystallizer starts to work, the heating device 2 is started first, and the temperature in the tank body 1 of the crystallizer is respectively set to five temperature zones: the first temperature zone is 180°C-185°C; the second-stage temperature zone is 190-200°C; The temperature zone of the first stage is 205~210℃; the temperature zone of the fourth zone is 215~225℃; the temperature zone of the fifth zone is 230~240℃. The optimum temperature for each area is 183°C for the first stage; 195°C for the second stage; 207°C for the third stage; 219°C for the temperature region; and 232°C for the temperature region. Temperature is the main factor affecting the quality of refined tin and solder in the crystallizer. The temperature in the tank body 1 of the crystallization machine is set to five temperature zones respectively. When the crude tin enters the crystallizer, it is cooled by spraying water, so that the crude tin liquid rapidly drops from 230°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com