Method for establishing production line control knowledge base based on object-oriented thinking

An object-oriented, method-based technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as reducing production efficiency, increasing maintenance costs, reducing production profits, etc., to improve production efficiency and reduce maintenance. cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

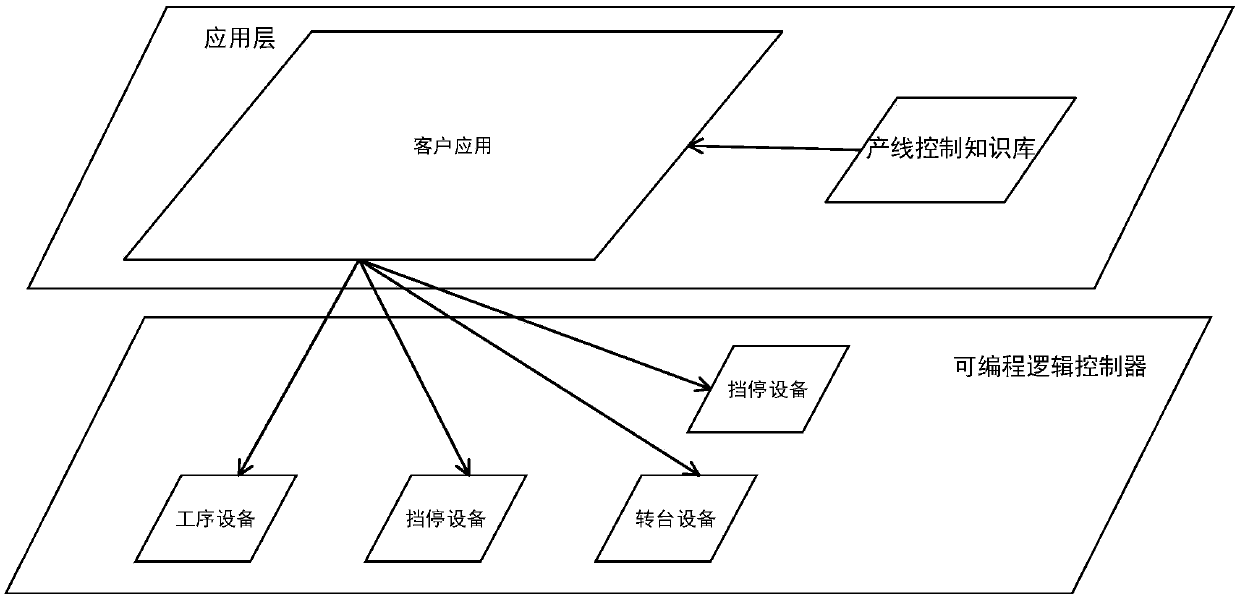

[0053] In order to make the object, technical solution and advantages of the present invention clearer and clearer, the detailed description will be given below with reference to the accompanying drawings.

[0054] The present invention can abstract the control logic of the underlying production line and establish a general knowledge base that is continuously improved, so that the application layer can finally complete the production line control programming by dragging and configuring, reduce the workload of production personnel, improve work efficiency, and increase It improves production flexibility and enables rapid reconfiguration of production lines in discrete manufacturing industries.

[0055] This solution uses the following steps to complete the establishment of the production line control knowledge base:

[0056] 1) Definition of event-driven interface between function blocks.

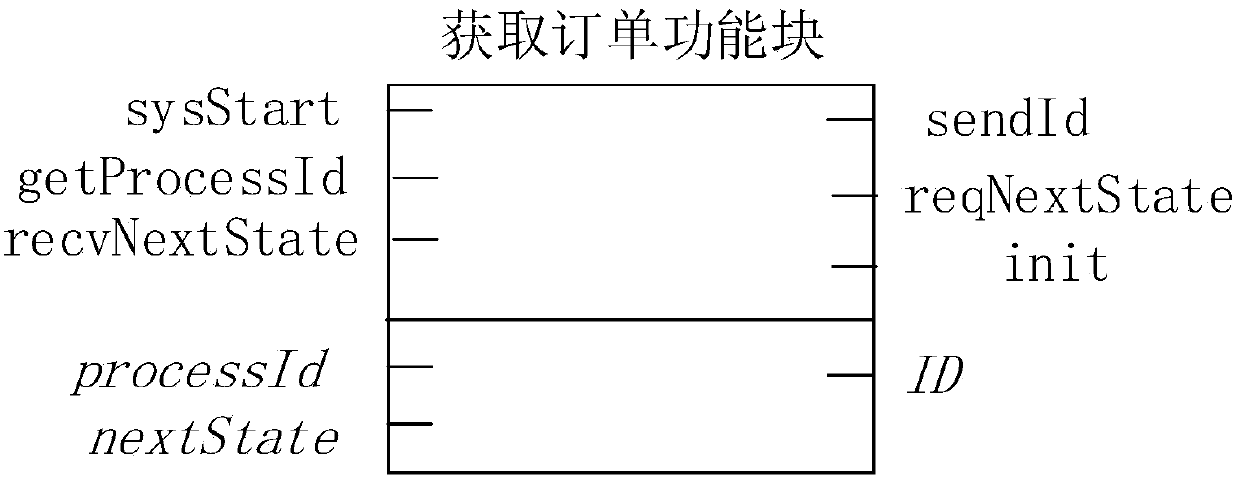

[0057] 2) Establishment of production order acquisition function block.

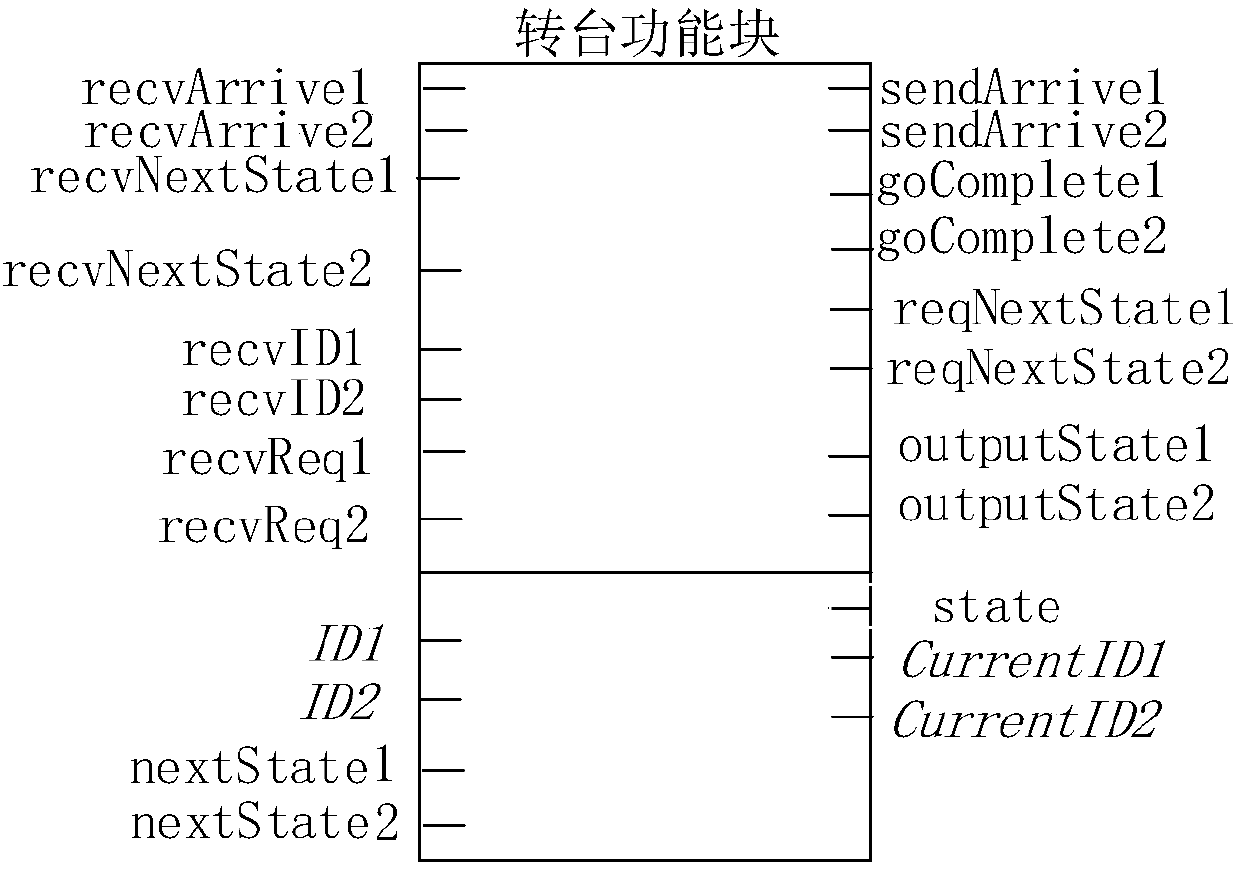

[0058] 3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com