Milled rice with whole embryos and processing method and application of milled rice

A processing method and germ technology, applied in the processing of polished rice and the field of polished rice, can solve the problems of incompleteness, bad taste, incomplete germ retention, etc., and achieve the effect of high retention rate of germs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

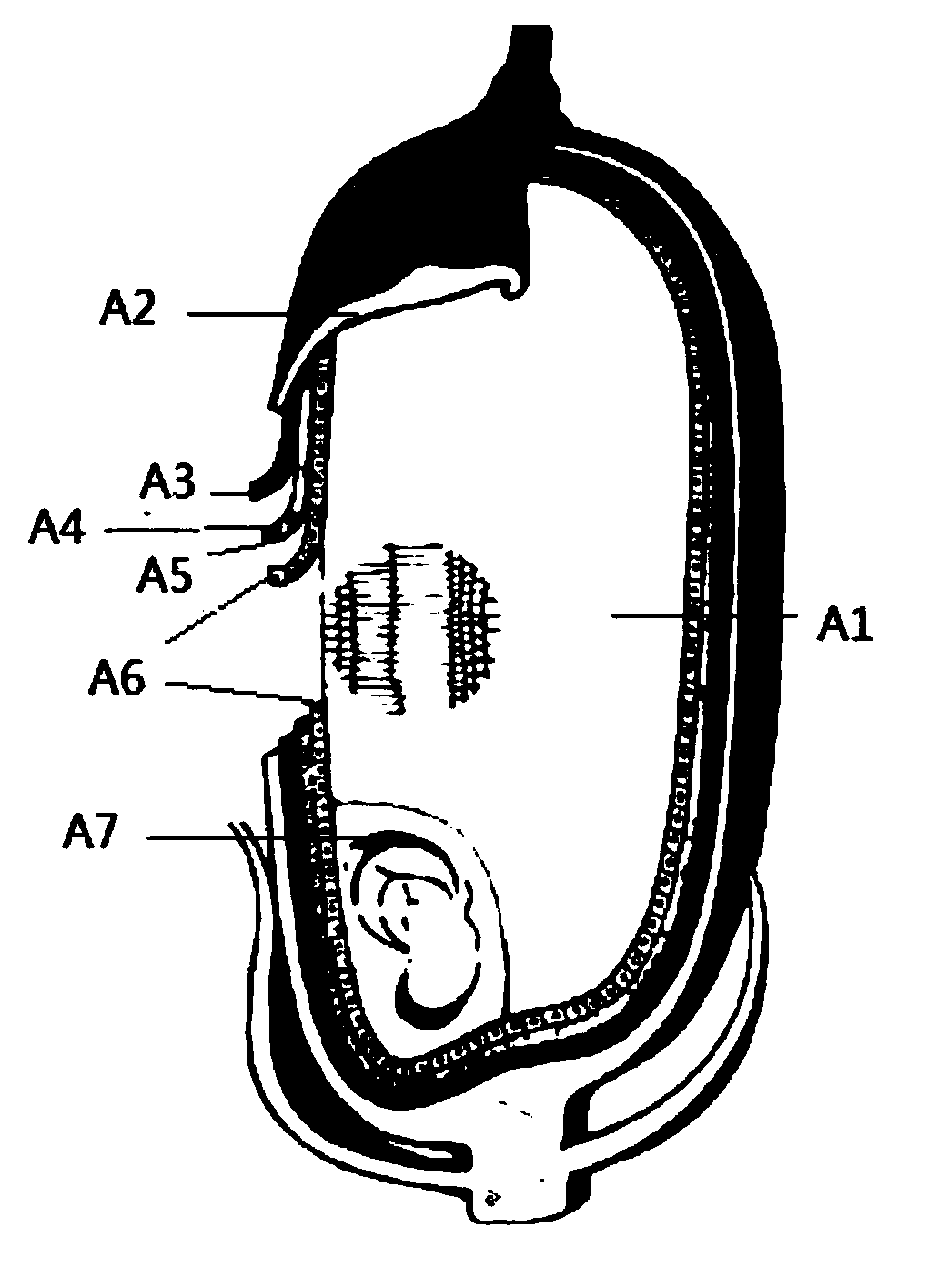

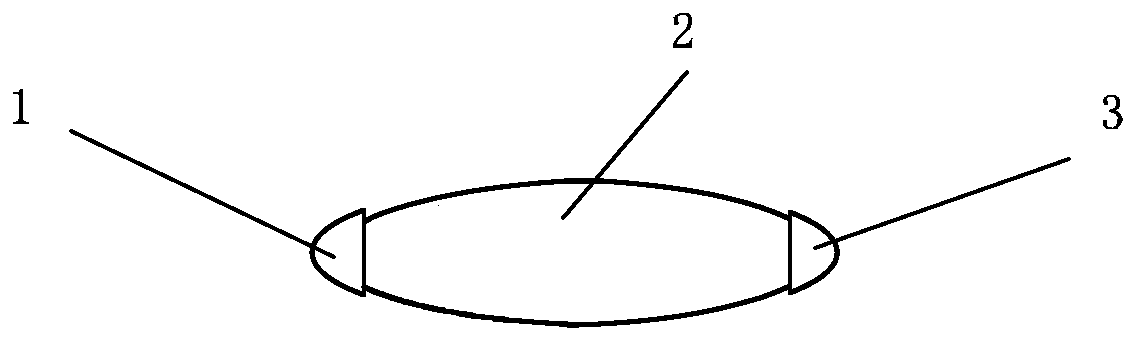

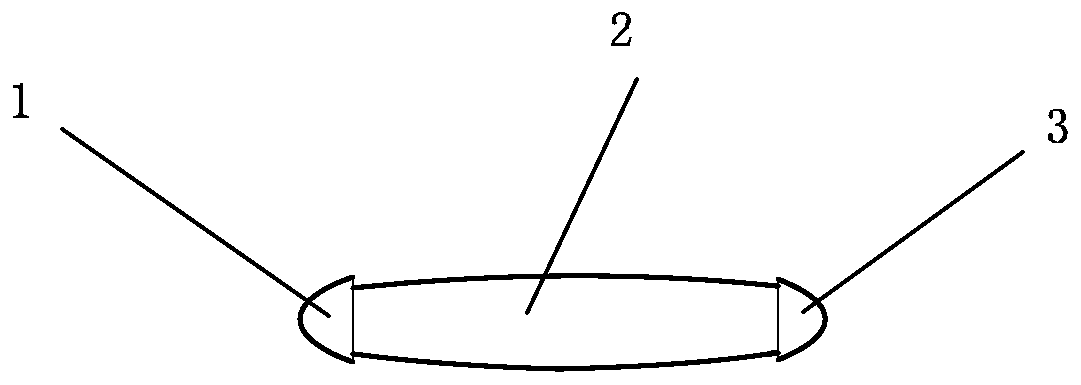

[0016] Specific implementation mode one: the following combination figure 2 and image 3 , Figure 4 This embodiment will be specifically described. The polished rice with the whole germ described in this embodiment is composed of the left rice tip section 1, the middle section 2 and the right rice tip section 3 along the length direction, and the middle section 2 is from the right end of the left rice tip section 1 and the The left end of the rice tip section 3 is recessed into the formed saddle-shaped rice grain body.

[0017] The processing method of the polished rice with the whole germ, it comprises the following steps: 1. select multi-grain brown rice; No. 1 flat plate 4 withstands the tip of the left rice tip section 1 of each brown rice grain, utilizes No. 2 flat plate 5 to withstand the tip of the right rice tip section 3 of each brown rice grain, and No. 1 flat plate 4 and No. 2 flat plate 5 are arranged in parallel , No. 1 flat plate 4 has pit 9 at the tip cont...

specific Embodiment approach 2

[0019] Specific implementation mode two: the following combination Figure 4 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is: No. 1 flat plate 4 surrounds the tip of the left rice tip section 1 of brown rice grains and is provided with a No. 1 coating positioning unit 6, and No. 2 flat plate 5 surrounds the right side of brown rice grains. A No. 2 coating positioning unit 7 is provided at the tip contact point of the rice tip section 3 . With such setting, the covering effect is better.

specific Embodiment approach 3

[0020] Specific implementation mode three: the following combination Figure 5 This embodiment will be specifically described. The differences between this embodiment and Embodiment 2 are:

[0021] Step 2 of the processing method, the brown rice is arranged in a circular array and the length direction plumb of the rice grains is set; 4, the outer surface of all the brown rice grains X middle section 2 is ground and polished by using a flexible abrasive belt 21 moving at high speed . The flexible abrasive belt 21 is driven by a power wheel 22 and guided by a No. 1 guide wheel 23 and a No. 2 guide wheel 24 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com