Device for improving dehydrating efficiency of vacuum belt dehydrator and mounting method

A vacuum belt and dehydrator technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of poor dehydration effect of vacuum belt dehydrator, achieve improved dehydration effect, convenient disassembly and assembly, and good matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

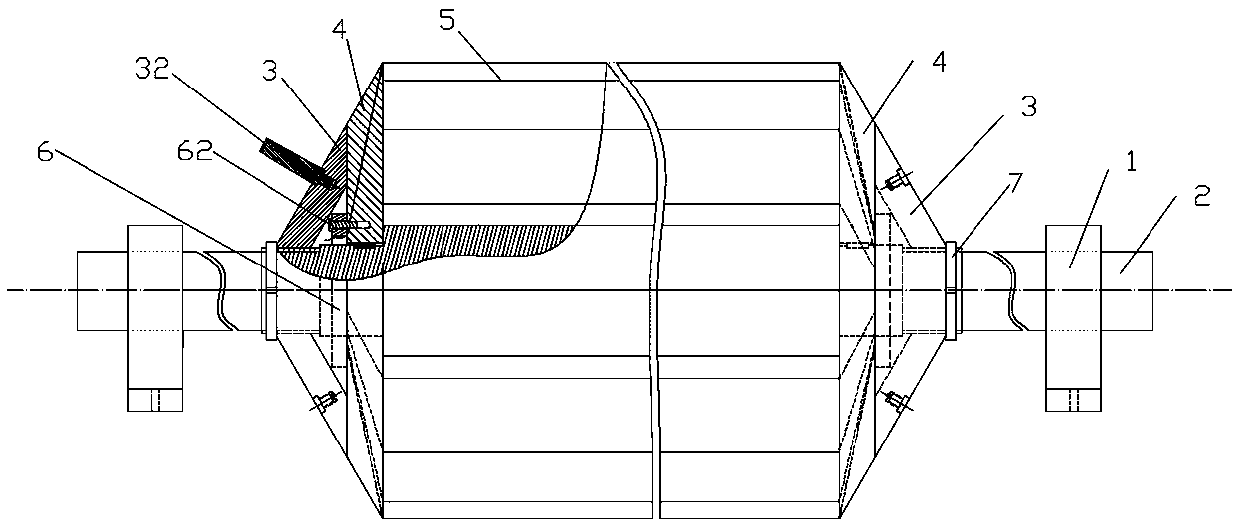

[0058] In preferred embodiment one of the present invention, 16 roller wire grooves 43 are set on the guide wheel 2 4, and 16 roller wire grooves 43 are also arranged, which are set in one-to-one correspondence with the roller wire grooves 43. axis parallel.

[0059] In preferred embodiment 2, 16 roll grooves 43 are set on the guide wheel 2 4, the number of roll lines 5 is a multiple of 16, the roll lines 5 are evenly arranged in the roll grooves 43, and the middle parts of the roll lines 5 are staggered The arrangement is symmetrical to the plane perpendicular to the midpoint of the rotating shaft 2, so as to ensure that the roller line 5 is evenly stressed and does not deviate during the movement.

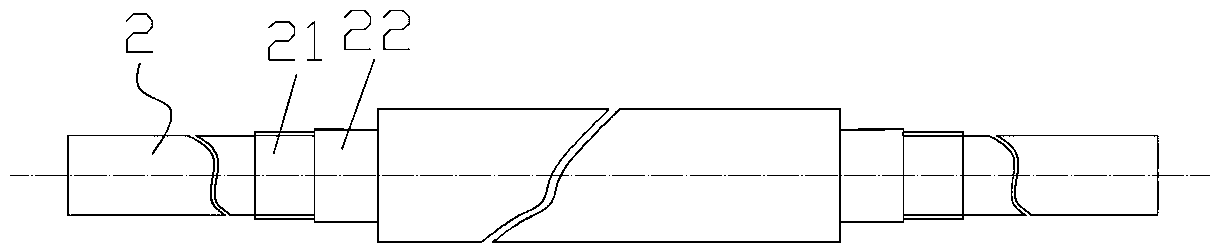

[0060] Such as image 3 As shown, further, the first step 21 is provided with an external thread, the guide wheel one 3 is provided with an internal thread matching the external thread, and the outer bottom surface of the guide wheel one 3 is provided with a fastening nut 7, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com