An automatic punching device and method for double-intersecting lines of circular tubes

A technology of automatic punching and intersecting lines, which is applied in the field of mechanical processing, can solve the problems of restricting the upgrading and development of the pipe equipment manufacturing industry, the inconvenience of steel pipe assembly and welding process, and the low symmetry precision of punching products, so as to achieve high processing efficiency, The effect of wide application range and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

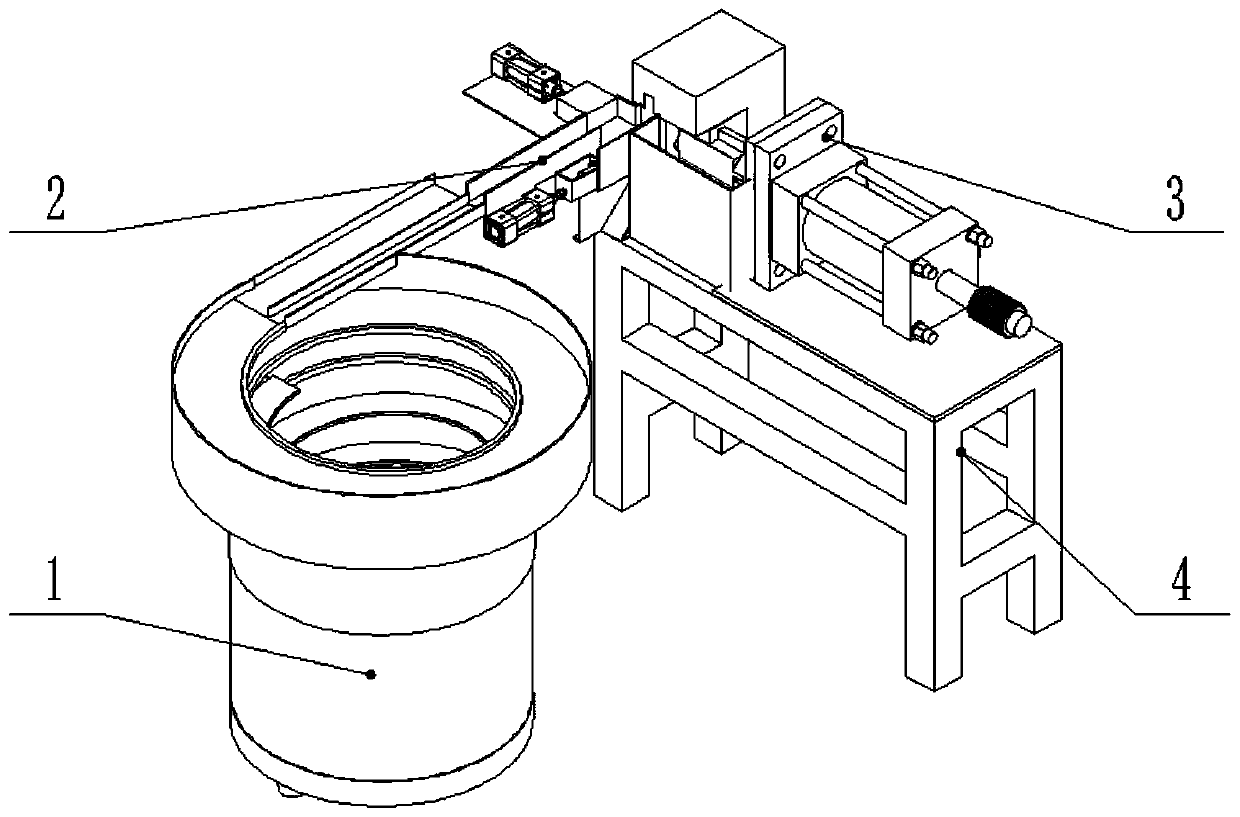

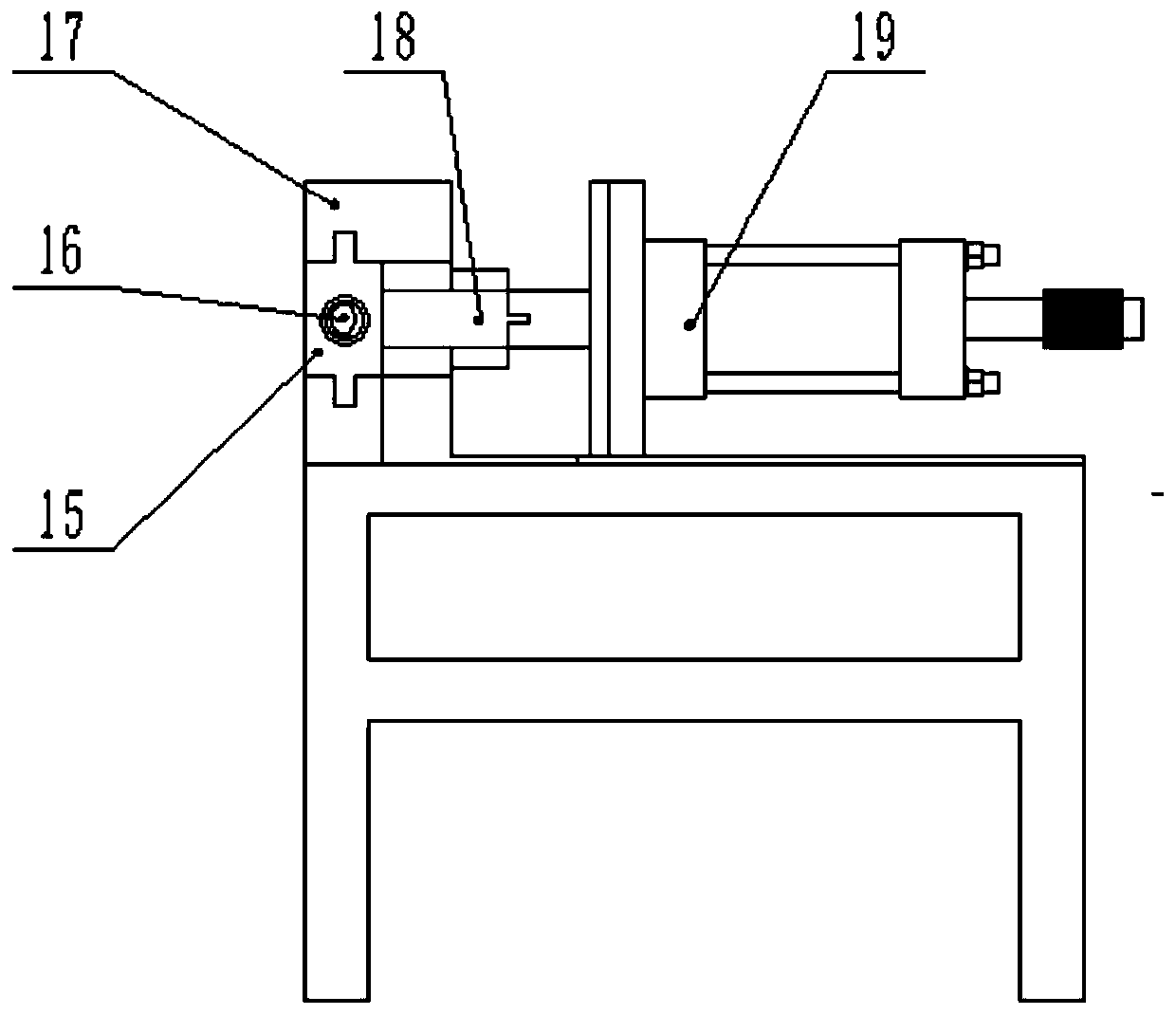

[0042] This embodiment provides a double-intersecting line automatic punching device for circular tubes, which is especially suitable for punching short tubes. It includes a vibrating plate 1, a feeding mechanism 2, a punching mechanism 3 and a workbench 4. On one side of the feeding mechanism 2 , the punching mechanism 3 is arranged on the other side of the feeding mechanism 2 , and the punching mechanism 3 is installed above the working table 4 .

[0043] The vibrating plate 1 is an existing structure, which will not be repeated here.

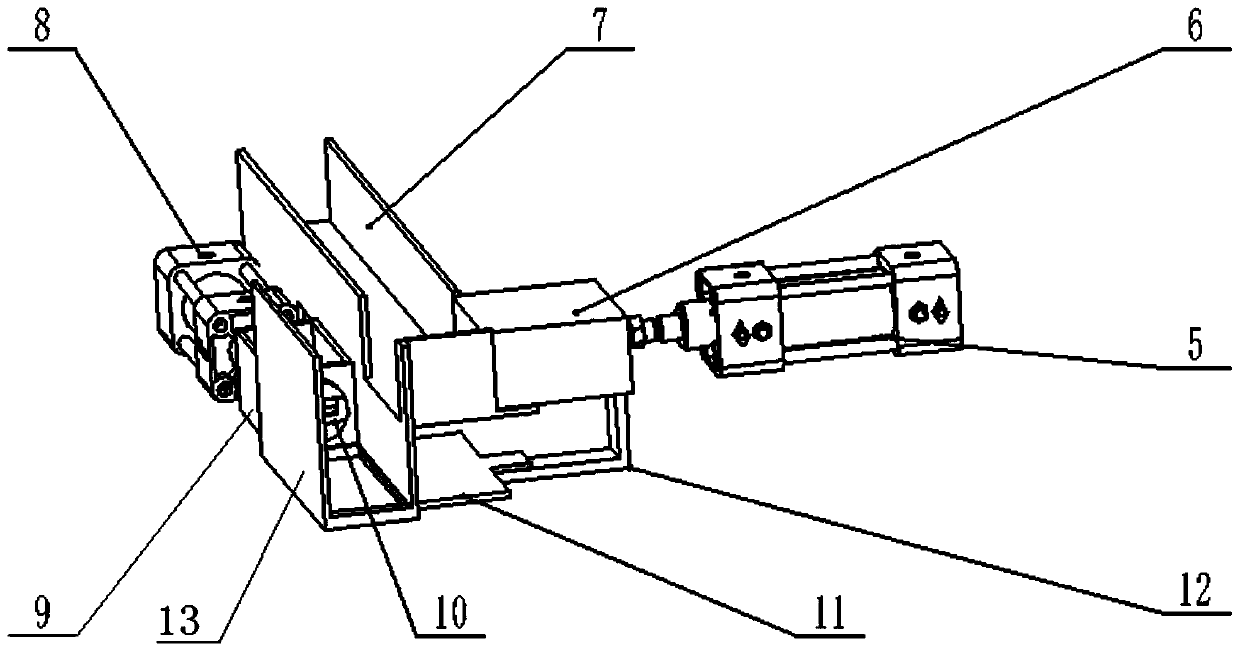

[0044] Such as figure 2 As shown, the feeding mechanism 2 includes a chute, a pushing mechanism, and a clamping and pushing mechanism, wherein the chute includes an upper chute 7 and a working chute 13, such as Figure 6 shown.

[0045] One end of the feeding chute 7 is connected with the vibration plate 1, and the other end is connected with the working chute 13.

[0046] Further, the working chute 13 is fixed on one side of the upper ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com