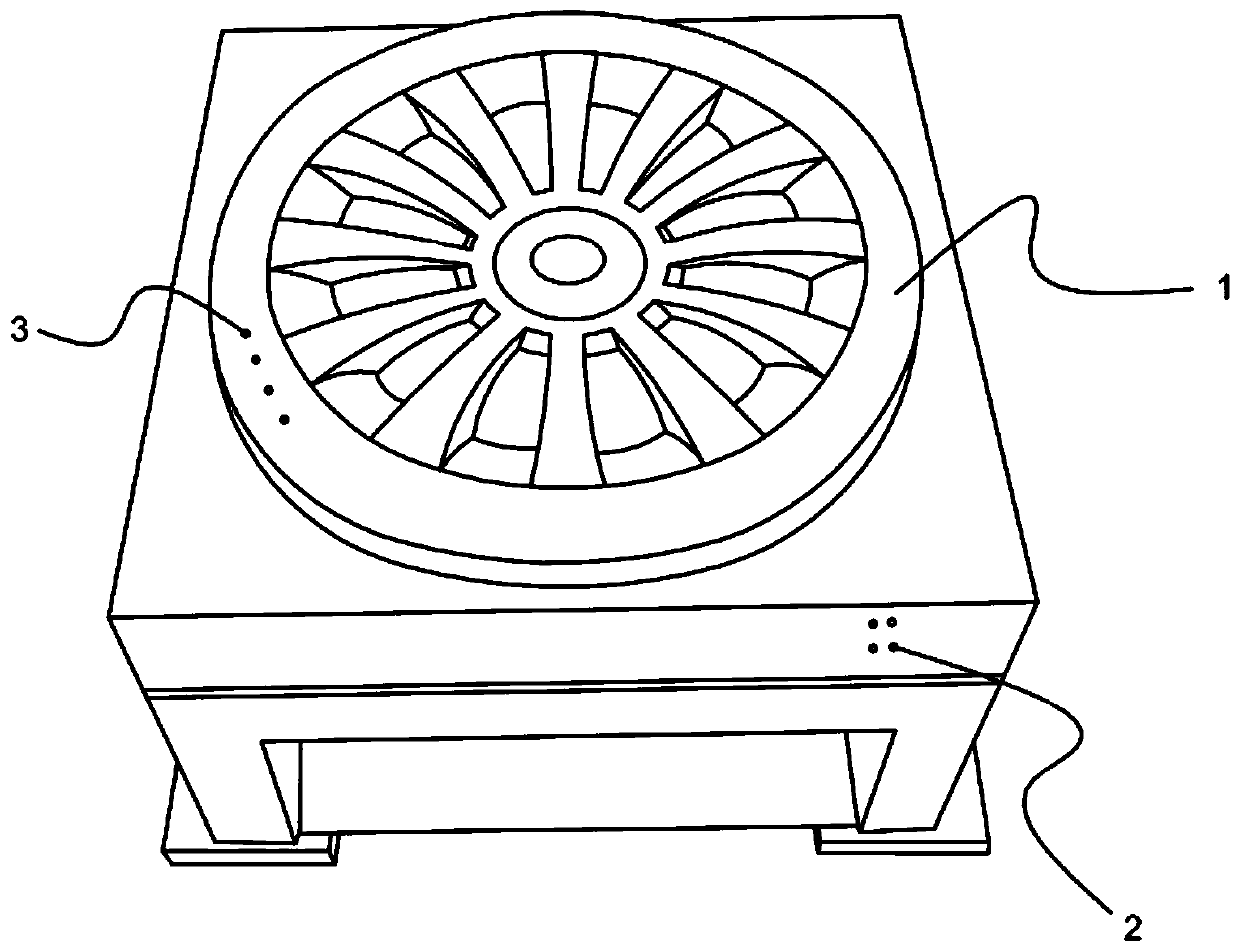

Manufacturing method of high-strength alloy hub

A high-strength alloy and manufacturing method technology, applied in the field of auto parts, can solve problems such as installation, inconvenient use, wheel hub cracking, and car safety issues, and achieve the effects of reducing production costs, increasing service life, and strengthening strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, a method for manufacturing a high-strength alloy wheel hub, comprising the following steps:

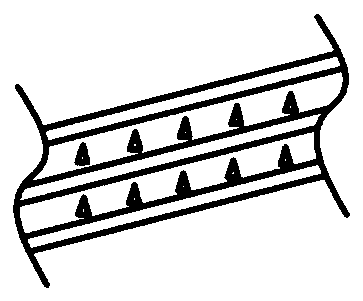

[0042] A. The carbon fiber is made into a strip with a diameter of 1 cm, and the cross section of the carbon fiber strip is an isosceles triangle;

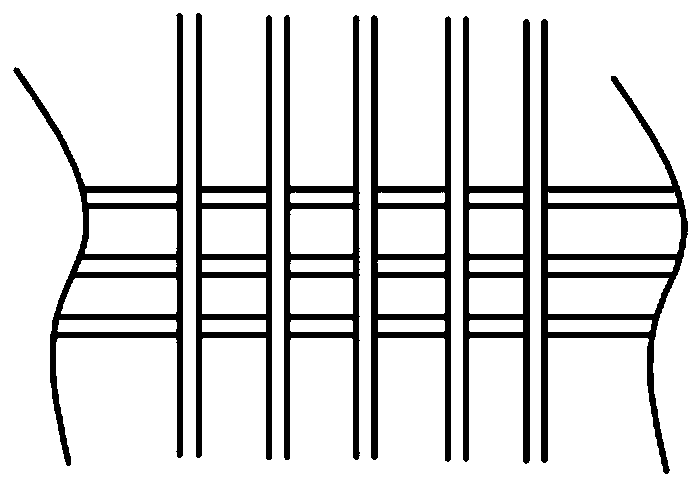

[0043] B. The four side walls of the hub mold are provided with the first horizontal pores, and the top surface of the hub mold is provided with the second longitudinal pores, wherein the hole walls of the second pores are straight walls, and the first pores are straight. The hole wall is a straight wall;

[0044] Insert the carbon fiber strip through the fine holes around the wheel mold, and then insert it downward from the fine holes on the top surface of the wheel mold until it touches the bottom surface inside the wheel mold;

[0045] C. Inject the aluminum alloy solution into the wheel hub mold with carbon fiber strips, and cool it to form, and cool to room temperature by alternating water-cooling quenching and ...

Embodiment 2

[0050] Embodiment 2, a method for manufacturing a high-strength alloy wheel hub, comprising the following steps:

[0051] A. The carbon fiber is made into a strip with a diameter of 0.8cm, and the cross section of the carbon fiber strip is an isosceles triangle;

[0052] B. The four side walls of the hub mold are provided with the first horizontal pores, and the top surface of the hub mold is provided with the second longitudinal pores, wherein the hole walls of the second pores are straight walls, and the first pores are straight. The hole wall of the hole is an inclined wall with both inner and outer ends of the hole wall on the same horizontal plane;

[0053] Insert the carbon fiber strip through the fine holes around the wheel mold, and then insert it downward from the fine holes on the top surface of the wheel mold until it touches the bottom surface inside the wheel mold;

[0054] C. Inject the aluminum alloy solution into the wheel hub mold with carbon fiber strips, and ...

Embodiment 3

[0059] Embodiment 3, a method for manufacturing a high-strength alloy wheel hub, comprising the following steps:

[0060] A. The carbon fiber is made into a strip with a diameter of 1 cm, and the cross section of the carbon fiber strip is an equilateral triangle;

[0061] B. The four side walls of the hub mold are provided with the first horizontal pores, and the top surface of the hub mold is provided with the second longitudinal pores, wherein the hole walls of the second pores are straight walls, and the first pores are straight. The hole wall of the hole is an inclined wall with both inner and outer ends of the hole wall on the same longitudinal plane;

[0062] Insert the carbon fiber strip through the fine holes around the wheel mold, and then insert it downward from the fine holes on the top surface of the wheel mold until it touches the bottom surface inside the wheel mold;

[0063] C. Inject the aluminum alloy solution into the wheel hub mold with carbon fiber strips,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com