A kind of refining method of acetylated impurity of vasopressin

A refining method, the technology of acetylation, which is applied in the field of refining acetylated impurities of vasopressin, can solve the problems of uneconomical, large amount of hazardous waste liquid, and high cost of waste liquid treatment, so as to reduce the amount of hazardous waste generated and optimize production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In the following examples, the preparation method of the crude vasopressin acetylated impurity solution includes: (1) preparing the crude acetylated impurity of reduced vasopressin by solid-phase synthesis; (2) the acetylated impurity of reduced vasopressin The crude impurity product is dissolved and diluted to obtain a crude product solution of acetylated impurities of reduced vasopressin; (3) the crude product solution of acetylated impurities of reduced vasopressin is subjected to an oxidation process to obtain the crude product solution of acetylated impurities of vasopressin.

[0053] The solid-phase synthesis method includes the following steps: using Rink Amide MBHA resin as a starting material, using Fmoc-protected amino acids as monomers, using HOBt / DIC as a condensation agent, and sequentially connecting amino acids one by one; adding peptide cutting reagents to carry out Cut the peptide, add methyl tert-butyl ether for precipitation, and obtain the crude produ...

Embodiment 1

[0054] Example 1 Load&Lock4002 preparative column with inner diameter of 50mm

[0055] Using Load&Lock dynamic axial compression and static locking technology, the packing is as described ODS-AQ, pore size 10nm, particle size 10μm, packed to a column bed pressure of 1000psi, Varian chromatography packing system, 300g dry powder as described ODS-AQ super water-resistant filler, 600mL isopropanol is stirred and homogenized, poured into a Load&Lock4002 preparation column with an inner diameter of 50mm, the compression ratio is 1.5:1, and the carrier gas is N 2 , adjust the carrier gas pressure so that the oil pressure gauge pressure is 1500psi, and dynamically axially compress to a column bed height of 25cm, which is used as a preparative column for reverse-phase enrichment, reverse-phase salt conversion and reverse-phase purification schemes.

Embodiment 2

[0056] Example 2 Reverse-phase enrichment, reverse-phase salt conversion and reverse-phase purification of the crude product solution of vasopressin acetylation impurity

[0057] Instrument: Varian SD-1 high pressure liquid phase preparation system

[0058] Chromatographic column: the preparation column Load&Lock400250 * 250mm of embodiment 1, packing is ODS-AQ has a particle size of 10 μm and a pore size of 10 nm.

[0059] The structural formula of the acetylated impurity of vasopressin is The concentration of the crude acetylated impurity solution of reduced vasopressin is 1 mg / mL, and the solvent of the crude acetylated impurity solution of vasopressin is an aqueous solution containing trifluoroacetic acid and acetic acid.

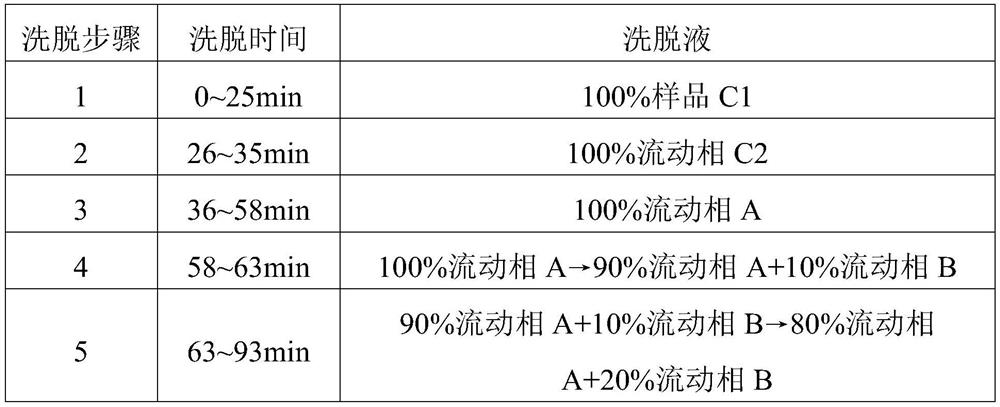

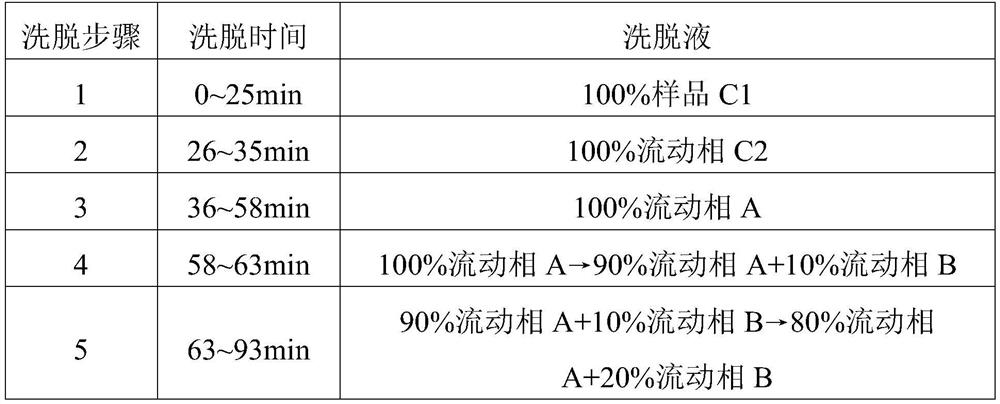

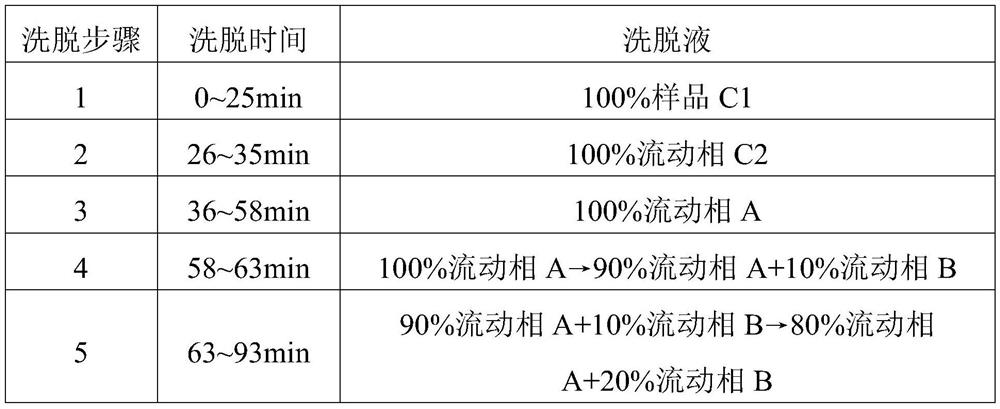

[0060] Mobile phase A is 0.02% acetic acid / water solution by volume, mobile phase B is 0.02% acetic acid / acetonitrile by volume, and sample C1 is the crude product solution of acetylated impurities of vasopressin. The HPLC purity of the acetylated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap