Liftable wave-making system

A wave-making and wave-pushing board technology, which is applied in the test field, can solve the problems of increasing the cost of the wave-pushing board and increasing the control accuracy of the wave-pushing board, and achieves the effects of simple structure, reduced design difficulty, and improved wave-making stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

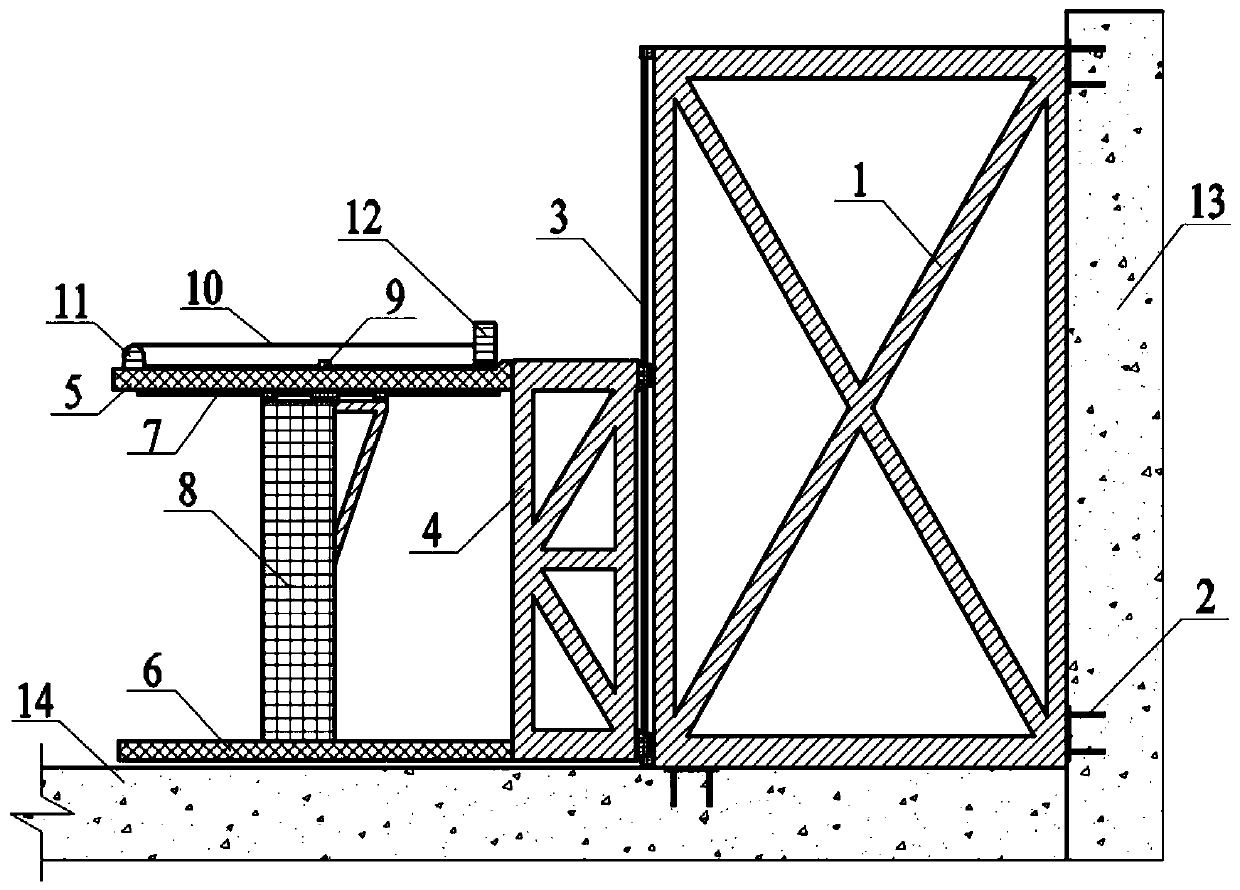

[0013] The invention relates to a liftable wave-making system, which is used to create wave effects of different water depths, and is installed in a pool. In this embodiment, the length, width, and depth of the pool are 80m, 60m, and 3m respectively, and the flow-making requirement is 0.3 m / s, and the maximum wave height is 0.4m. The liftable wave-making system consists of a support frame 1, rivets 2, a vertically moving slide rail 3, a moving frame 4, an upper support plate 5, a lower support plate 6, a wave pushing plate track 7, a wave pushing plate 8, a linkage 9, Transmission belt 10, transmission wheel 11, drive motor 12 form. Among them, the support frame 1 is a steel structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com