Power lithium battery protective housing and manufacturing process thereof

A lithium battery and protective shell technology, applied in the field of power lithium battery protective shells and their manufacturing processes, can solve the problems of difficult unification of standards, large differences in monomers, heavy shell quality, etc., and achieve light weight, strong plasticity, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

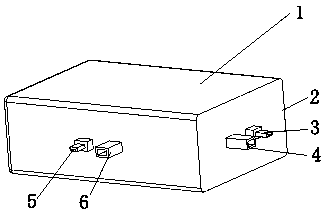

[0037] like Figure 1-7 As shown, a power lithium battery protective case includes an aluminum box 1 and a cover 2. The middle position of the cover 2 is equally divided with a main electrode male plug 3 and a main electrode female plug 4, and the middle position of the side of the aluminum box 1 is equally divided. The secondary electrode male plug 5 and the secondary electrode female plug 6 are separately provided, the main electrode male plug 3 and the secondary electrode male plug 5 are electrically connected by wires, the main electrode female plug 4 and the secondary electrode female plug 6 are electrically connected by wires, and the The wire is embedded in the wire groove of the aluminum box 1, and the width of the wire groove is matched with the wire diameter of the wire. The outer shells of the main electrode male plug 3, the main electrode female plug 4, the secondary electrode male plug 5 and the secondary electrode female plug 6 are made of insulating material, an...

Embodiment 2

[0041] A manufacturing process of a power lithium battery protective case, characterized in that it comprises the following steps:

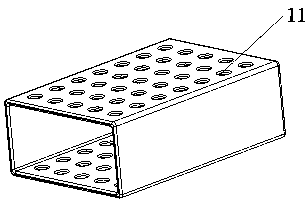

[0042] S1. Select the double-layer aluminum-plastic film to unwind, and punch a number of heat dissipation holes 8 on the mold;

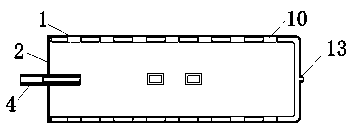

[0043] S2, the upper mold, heat sealing and shaping, to form the aluminum-plastic film cavity 10;

[0044] S3, opening a small hole at one end of the aluminum-plastic film cavity 10, and heat-sealing it with the inflation port 12;

[0045] S4. According to the size of the aluminum-plastic film cavity 10, the aluminum plate with a thickness of 0.35mm is machined out of the aluminum box 1 and the cover 2;

[0046] S5, put the aluminum-plastic film cavity 10 into the aluminum box 1, pull out the inflation port 12 from the aluminum box 1, and fix it with the pressure ring 13;

[0047] S6. Fill the aluminum-plastic film cavity 10 with helium gas 14 through the inflation port 12, and the inflation pressure is 0.2 MPa, and ...

Embodiment 3

[0051] A manufacturing process of a power lithium battery protective case, characterized in that it comprises the following steps:

[0052] S1. Select the double-layer aluminum-plastic film to unwind, and punch a number of heat dissipation holes 8 on the mold;

[0053] S2, the upper mold, heat sealing and shaping, to form the aluminum-plastic film cavity 10;

[0054] S3, opening a small hole at one end of the aluminum-plastic film cavity 10, and heat-sealing it with the inflation port 12;

[0055] S4. The aluminum box 1 and the cover 2 are machined out of an aluminum plate with a thickness of 0.65 mm according to the size of the aluminum-plastic film cavity 10;

[0056] S5, put the aluminum-plastic film cavity 10 into the aluminum box 1, pull out the inflation port 12 from the aluminum box 1, and fix it with the pressure ring 13;

[0057] S6. Fill the aluminum-plastic film cavity 10 with helium gas 14 through the inflation port 12, and the inflation pressure is 0.35MPa, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com