Rotatable rolling brush assembly and cleaning device

A technology of cleaning device and rolling brush, which is applied in the direction of cleaning equipment, cleaning machinery, cleaning action control, etc., and can solve the problems of inability to successfully remove garbage particles, reduce cleaning efficiency, and block garbage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

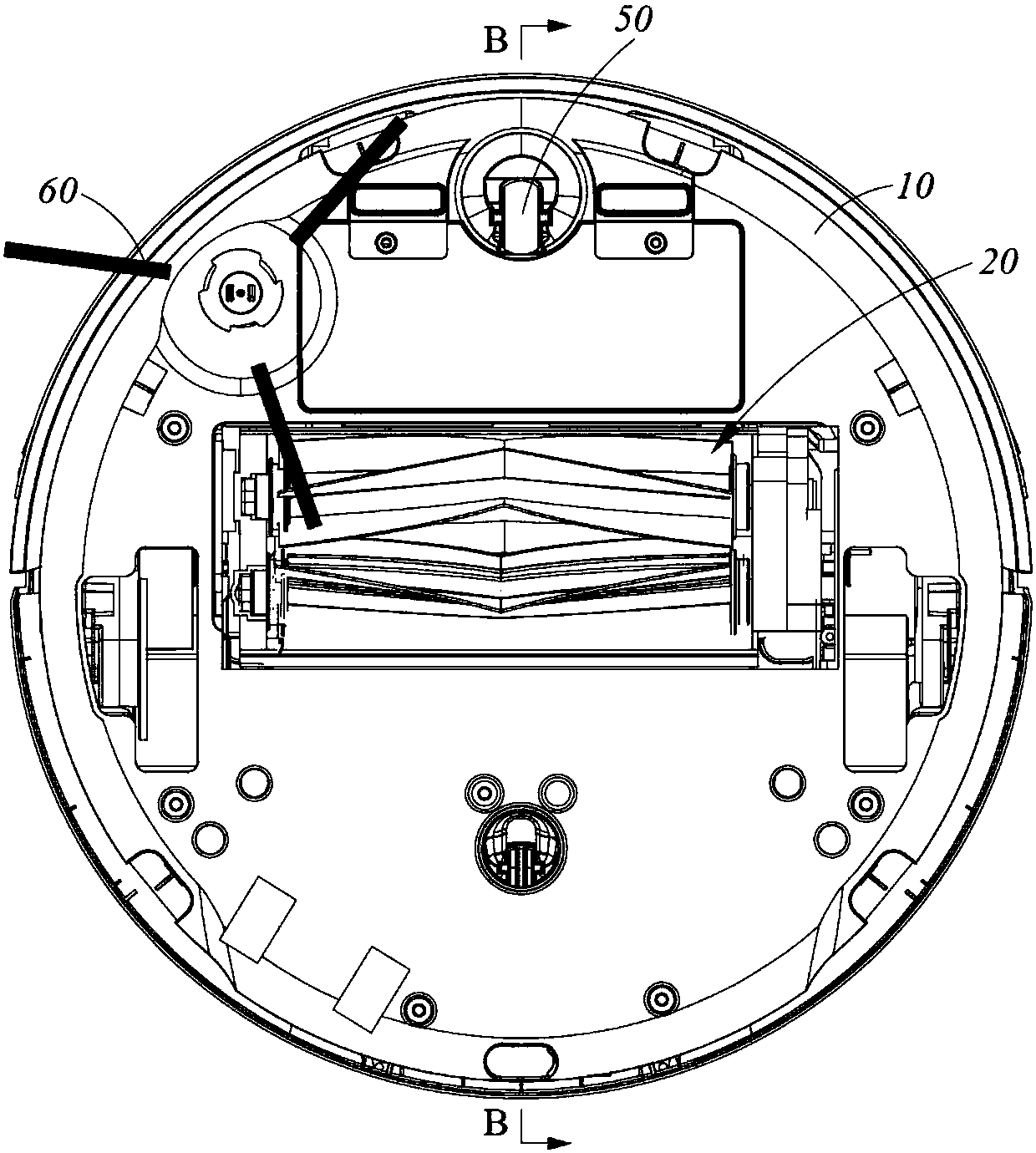

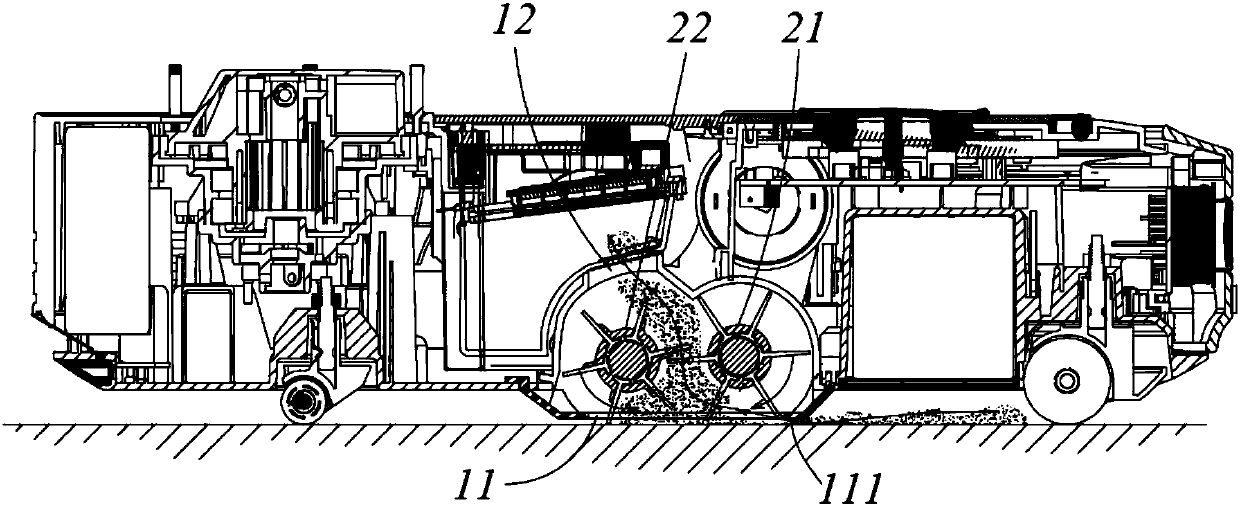

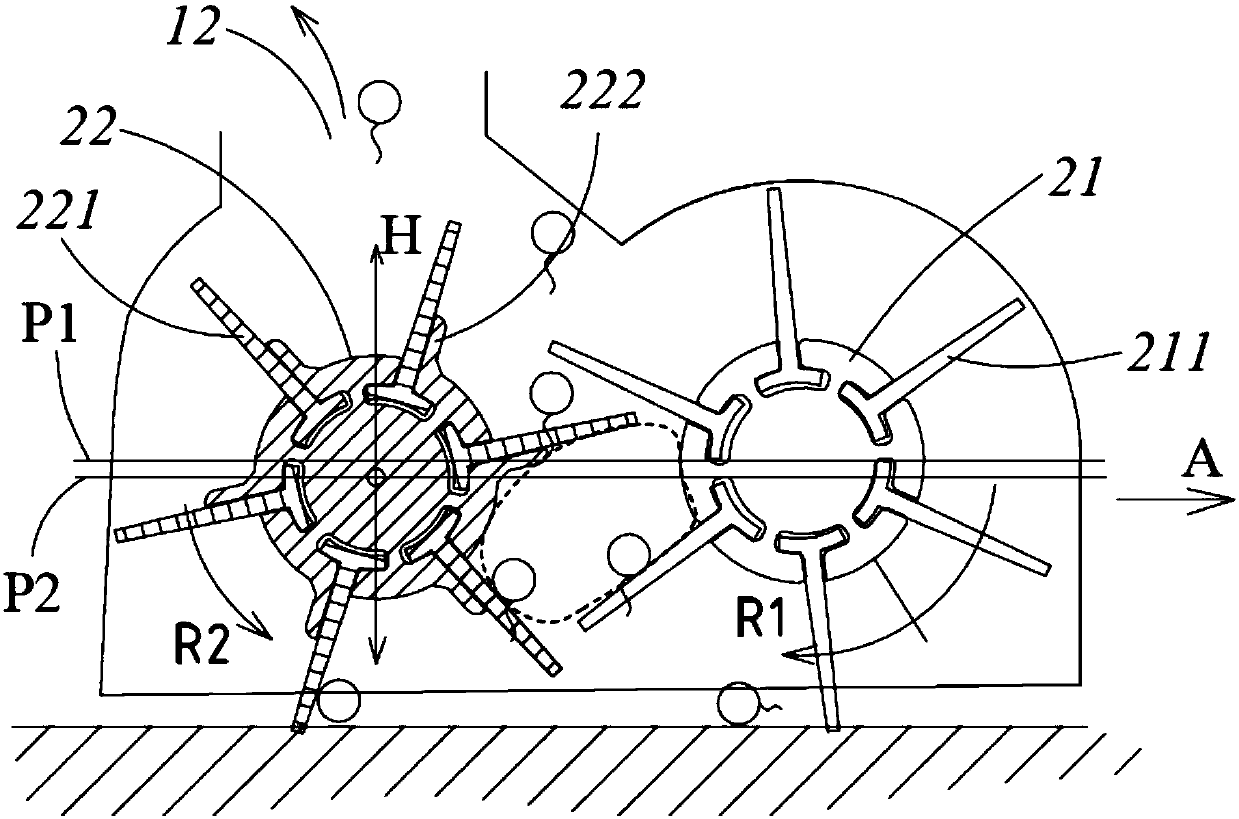

[0059] ginseng Figure 1 to Figure 2 Shown is a preferred embodiment of the cleaning device of the present invention, and the cleaning device of the present invention is described in detail by taking a sweeping robot as an example. The sweeping robot includes a body 10 and a rotatable roller brush assembly 20 arranged on the body 10. The rotatable roller brush assembly includes a first roller brush 21 and a second roller brush 22 arranged at intervals. The bottom of the body 10 is provided with a dust suction port 11, The first rolling brush 21 and the second rolling brush 22 correspond to the position of the dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com