Coupling bionic self-leveled type vibratory cleaning device for harvesting of high-humidity corn kernels

A cleaning device and self-leveling technology, which is applied in the direction of solid separation, chemical instruments and methods, grids, etc., can solve the problems of uneven distribution of cleaning mixtures, low seed penetration rate, high cleaning loss rate, etc., to achieve Reduce grain entrainment loss, enhance cleaning efficiency, improve cleaning efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

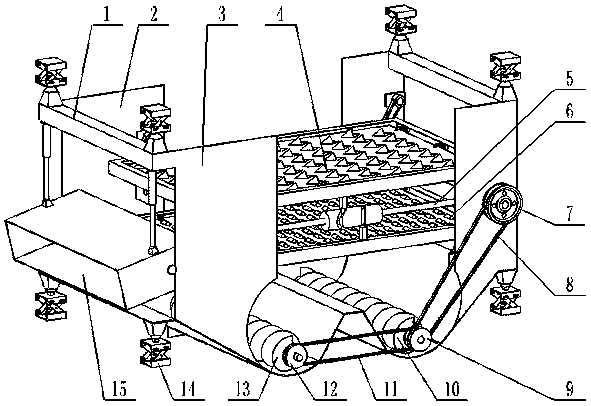

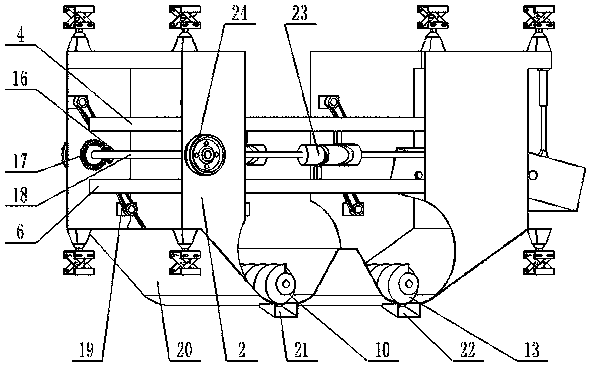

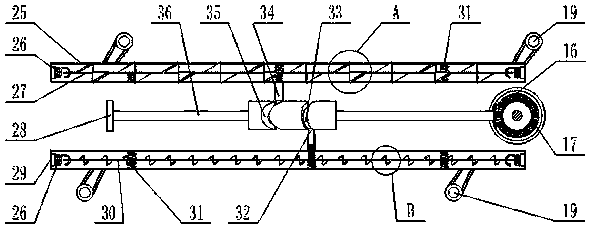

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6As shown, the present invention includes frame 1, right machine cover 2, left machine cover 3, upper cleaning mechanism 4, transmission mechanism 5, lower cleaning mechanism 6, front grain conveying auger 13, rear grain conveying auger 10 , leveling and damping seat 14, air inlet 15, rear grain opening 21, front grain opening 22 and bottom cover 20, right machine cover 2 is fixed on the right outside of frame 1, left machine cover 3 is fixed on the frame 1, the air inlet 15 is fixed on the front of the frame 1, the bottom cover 20 is fixed on the bottom outside of the frame 1, the upper cleaning mechanism 4 is installed on the inner side of the middle and upper part of the frame 1, and the lower cleaning mechanism 6 is installed on the Below the upper cleaning mechanism 4, the front grain conveying auger 13 is installed on the bottom front of the frame 1, the rear grain conveying auger 10 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com