Mold pressing and edge sealing device and edge sealing method thereof

An edge banding device and molding technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve problems such as unsatisfactory customers, product odor and VOC exceeding the standard, and achieve simple process, good appearance, and excellent odor VOC horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

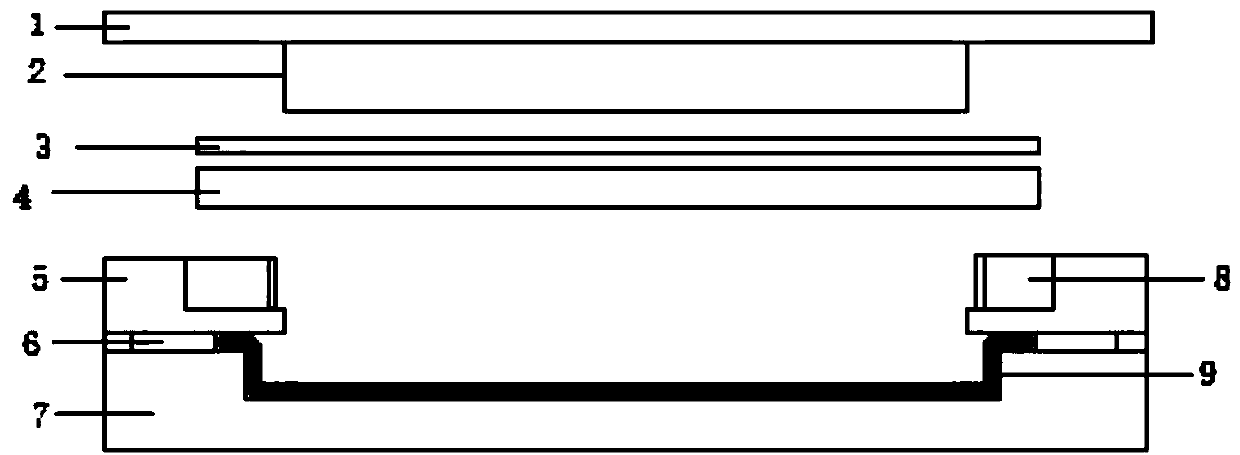

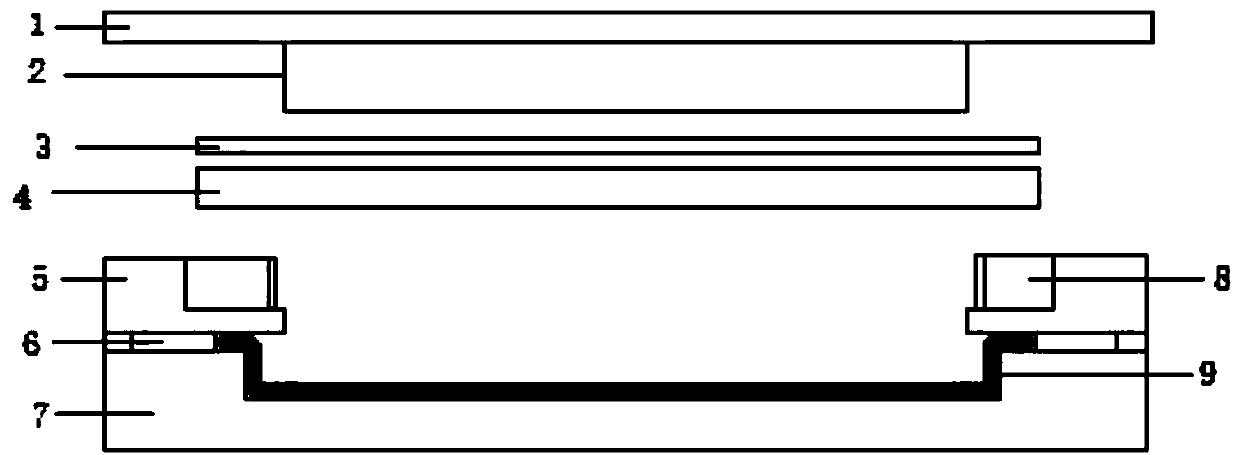

[0032] A molding edge banding device has a concave bottom mold 7, a pressure-cutting module 1 arranged above it, and an intermediate module 5 matched with the pressure-cutting module; the concave bottom mold 7 has a The groove of fabric 9, the length of groove is set to the length that product needs; Concave bottom mold 7 two ends have raised cushion block, and front fabric 9 length is longer than groove length, and long part is put on raised cushion block; An intermediate module 5 is arranged above the raised pad, and the intermediate module 5 is arranged in an L-shaped relative symmetry; a pressing-cutting module 1 is arranged at a corresponding place above the intermediate module 5, and a raised structure matching the shape of the intermediate module is arranged in the middle of the pressing-cutting module , the length of the raised structure is equal to the distance from the bottom edge of the middle module 5, and it just presses into the middle of the middle module 5 durin...

Embodiment 2

[0043] A method of molded edge banding using a molded edge banding device, S2 is that the honeycomb substrate is heated and softened in a heating device, and an automatic feeding mechanism transports the heated honeycomb panel substrate to be molded and edge sealed to an intermediate module; The bottom fabric 3 is placed on the top of the honeycomb substrate 4; S4 is the edge-pushing module 6 that wraps and seals the growing part of the front fabric 9, and glues the part of the front fabric 9 that is larger than the substrate to the bottom fabric 3 with glue. Made products. The discharge structure is used to discharge the products with pressure-cut and edge-banding. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com