Ink, and preparation method and applications thereof

A technology of ink and glycidyl ether, applied in the field of ink and its preparation, can solve the problems of inability to meet high-speed and high-frequency requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

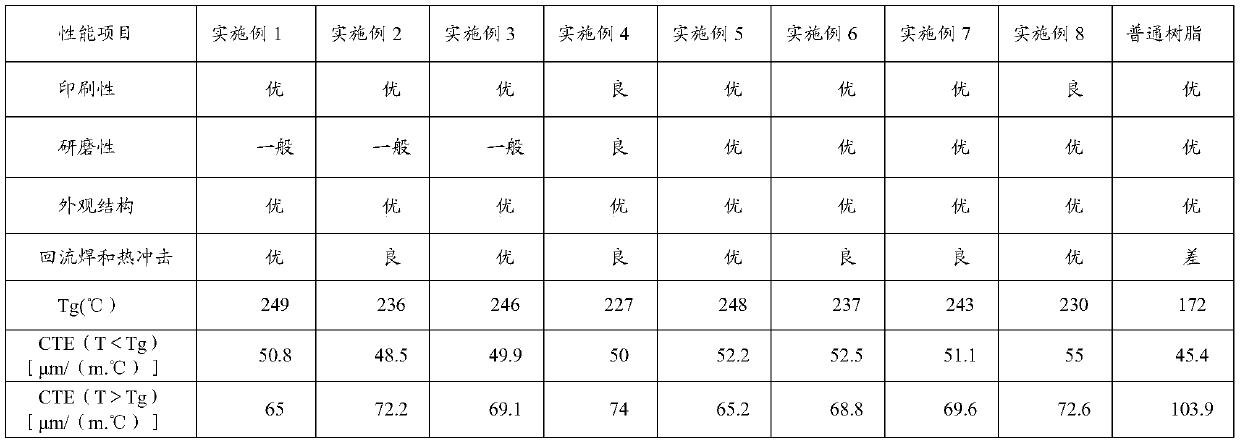

Examples

preparation example Construction

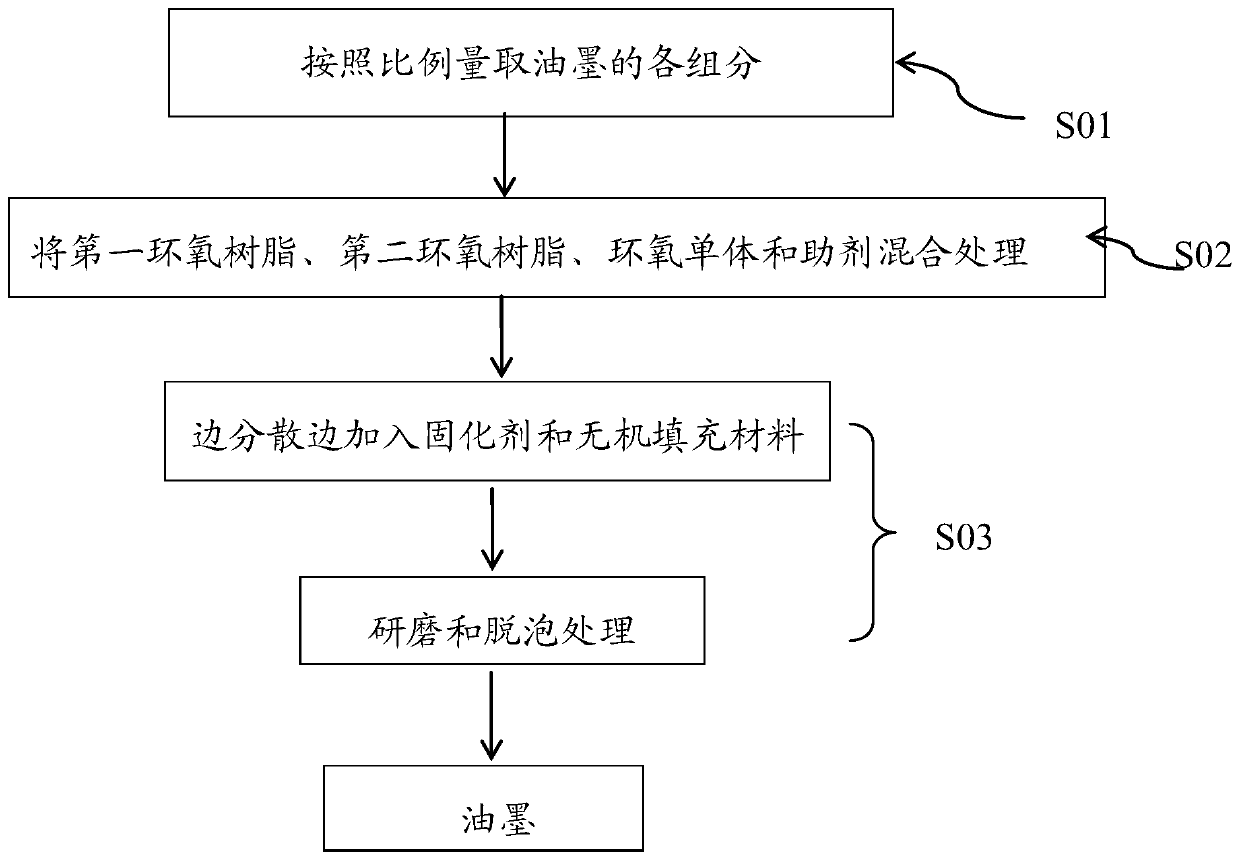

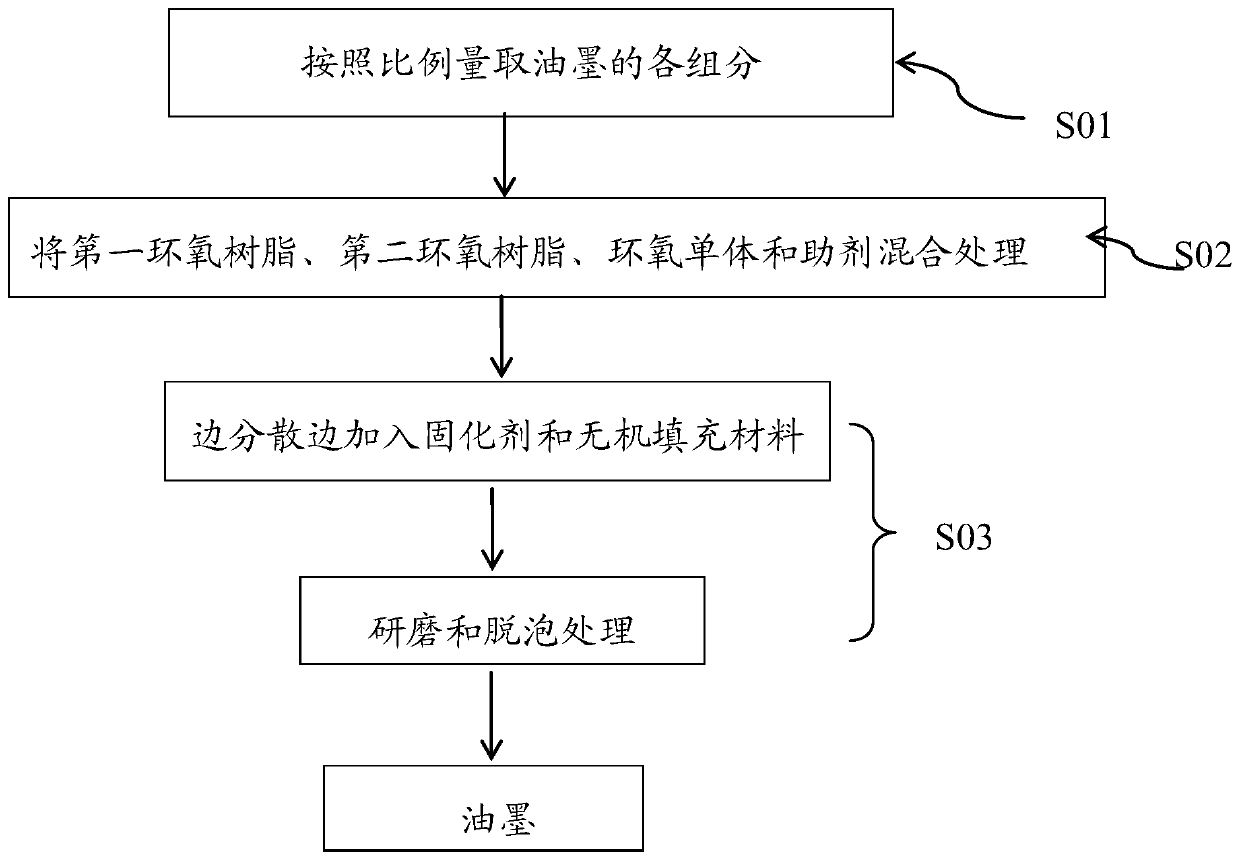

[0044] A kind of preparation method of ink,

[0045] Step S01: taking each component according to the components contained in the ink and the content of each component;

[0046] Step S02: uniformly mixing the first epoxy resin, the second epoxy resin, epoxy monomers and additives;

[0047] Step S03: adding curing agent and inorganic filler while dispersing, grinding the slurry to a certain fineness, and performing degassing treatment to form the ink.

[0048] Among them, step S03 is specifically to add curing agent and inorganic filler material while dispersing, control the temperature below 50°C, disperse at high speed for 15-20 minutes, and grind at least 3 times with three rollers until the inorganic filler material reaches a certain fineness. The density is less than or equal to 15 μm, and then transferred to a vacuum stirring and degassing machine for degassing until the material has no bubbles, and finally the material is divided and subjected to centrifugal degassing t...

Embodiment 1

[0052] This embodiment provides a kind of ink, and described ink comprises following mass percent: 4,4'-methylene bis (N, N-diglycidyl aniline) 20%, triglycidyl p-aminophenol 20% %, 1,4-cyclohexanedimethanol diglycidyl ether 2%, DDS0.2%, 2-methylimidazole trimeric isocyanate 2.8%, calcium carbonate 53.8%, BYK-110 1%, BYK- A550 0.2%.

[0053] Its preparation method comprises the following steps:

[0054] S11: 4,4'-methylene bis(N,N-diglycidyl aniline), triglycidyl p-aminophenol, 1,4-cyclohexanedimethanol diglycidyl ether, BYK-110, After BYK-A550 is mixed according to the ratio, it is dispersed evenly by the disperser at high speed;

[0055] S12: Add DDS, 2-methylimidazole isocyanate and calcium carbonate while dispersing, control the temperature below 50°C, disperse at a high speed for 15-20 minutes, and grind at least 3 times with three rollers to a certain fineness of 15 μm;

[0056] S13: Vacuum stirring and defoaming machine degasses until the material has no bubbles, and...

Embodiment 2

[0058] This embodiment provides an ink, and the ink includes the following mass percentages: 4,4'-methylene bis(N,N-diglycidyl aniline) 10%, tetraglycidyl-1,3 -Bisaminomethylcyclohexane 10%, triglycidyl p-aminophenol 20.3%, p-tert-butylphenyl glycidyl ether 1%, trimethylolpropane triglycidyl ether 1.5%, DDS 0.2%, 2-Methylimidazole trimeric isocyanate 2.8%, calcium carbonate 53%, BYK-110 1%, BYK-A550 0.2%.

[0059] Its preparation method refers to the preparation method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap