Coating composition for medical instruments

A technology of medical devices and compositions, applied in the direction of anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of inability to apply and promote, complex modification methods, high production costs, etc., and achieve excellent antibacterial properties and resistance Salt mist ability, excellent leveling effect, lubricity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

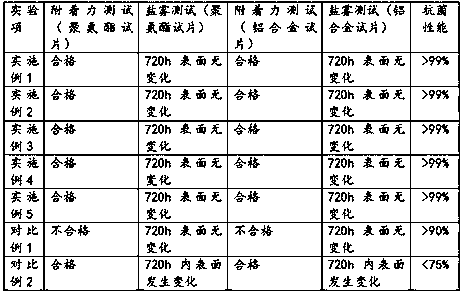

Examples

Embodiment 1

[0014] A coating composition for medical devices, characterized in that it comprises the following components in parts by weight: the components in parts by weight: polyvinyl acetate 19, ethylene-vinyl acetate latex 8, polyhexaethylene gluconate Methylguanidine 7, azobisisobutyronitrile 5, polyvinyl alcohol 13, dispersant 7, thickener 5, Rana antibacterial peptide 31, defoamer 4, pH regulator 1, ferric oxide hollow magnetic nano Microsphere 42, titanium silicon carbide ceramic powder 31, distilled water 17.

[0015] The Rana antibacterial peptide of the present invention can achieve excellent antibacterial effect through the synergistic effect with polyhexamethylene guanidine gluconate. In particular, the Rana antibacterial peptide of the present invention is mixed into iron ferric oxide hollow magnetic nanospheres and titanium silicon carbide ceramic powder to form a long-term antibacterial layer on the surface of the paint.

[0016] Further, the dispersant is sodium lauryl ...

Embodiment 2

[0022] A coating composition for medical devices, characterized in that it includes the following components in parts by weight: the components in parts by weight: polyvinyl acetate 32, ethylene-vinyl acetate latex 17, polyhexaethylene gluconate Methylguanidine 18, azobisisobutyronitrile 11, polyvinyl alcohol 29, dispersant 12, thickener 9, Rana antibacterial peptide 38, defoamer 7, pH regulator 3, ferric oxide hollow magnetic nano Microsphere 59, titanium silicon carbide ceramic powder 47, distilled water 26.

[0023] Further, the dispersant is methyl pentanol.

[0024] Further, the thickener is zirconia oxide.

[0025] Further, the defoamer is tributyl phosphate.

[0026] Further, the pH regulator is diethanolamine.

Embodiment 3

[0028] A coating composition for medical devices, characterized in that it comprises the following components in parts by weight: components in parts by weight: polyvinyl acetate 23, ethylene-vinyl acetate latex 11, polyhexaethylene gluconate Methylguanidine 12, azobisisobutyronitrile 7, polyvinyl alcohol 16, dispersant 9, thickener 6, Rana antimicrobial peptide 33, defoamer 5, pH regulator 1.5, ferric oxide hollow magnetic nano Microsphere 45, titanium silicon carbide ceramic powder 34, distilled water 19.

[0029] Further, the dispersant is gull gum.

[0030] Further, the thickener is zirconia oxide.

[0031] Further, the defoamer is tributyl phosphate.

[0032] Further, the pH regulator is diethanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com