A kind of aluminum-silicon alloy for cylinder liner and its preparation process

A technology of aluminum-silicon alloy and preparation process, which is applied in the field of aluminum-silicon alloy and preparation process for cylinder liners, to achieve the effects of reducing the types of additions, saving costs, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

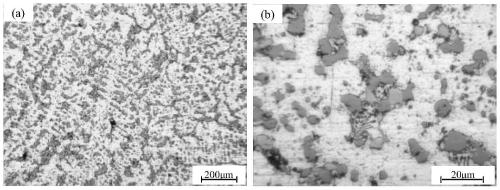

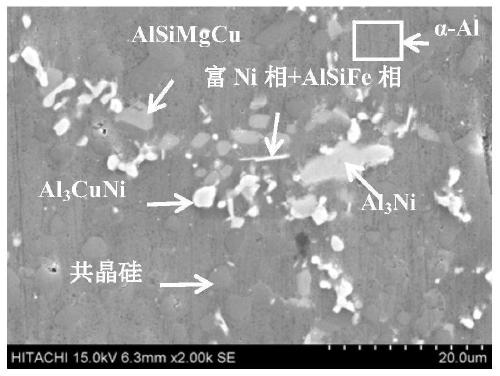

Image

Examples

Embodiment 1

[0037] An aluminum-silicon alloy for a cylinder liner, the components and mass percentages of the aluminum-silicon alloy are as follows: Si: 12%, Cu: 3%, Ni: 4%, Mg: 0.5%, Sr: 0.05%, mixed rare earth elements RE: 1%, impurity element: less than 1%, the balance is Al, and the sum of the total amount of each component is 100%.

[0038] The preparation process of the aluminum-silicon alloy for the above-mentioned cylinder liner:

[0039] 1) The target composition of aluminum-silicon alloy is quantitatively dosed with the following raw materials: industrial pure aluminum (purity ≥99.0%), industrial pure silicon (purity ≥98.0%), Al-50Cu, Al-10Ni, industrial pure magnesium (purity ≥99.8%) ), Al-10Sr, Al-10RE, in the Al-10RE, RE is a mixed rare earth, and (La+Ce)% in the mixed rare earth is ≥ 99.6%;

[0040] Quantitative ingredients are calculated based on the target composition of aluminum-silicon alloy and element burnout rate, among which, the element burnout rate is as follows: ...

Embodiment 2

[0051] An aluminum-silicon alloy for a cylinder liner, the components and mass percentages of the aluminum-silicon alloy are as follows: Si: 13.5%, Cu: 5%, Ni: 1%, Mg: 1.5%, Sr: 0.1%, mixed rare earth elements RE: 0.1%, impurity element: less than 1%, the balance is Al, and the sum of the total amount of each component is 100%.

[0052] The preparation process of the aluminum-silicon alloy for the above-mentioned cylinder liner:

[0053] 1) The target composition of aluminum-silicon alloy is quantitatively dosed with the following raw materials: industrial pure aluminum (purity ≥99.0%), industrial pure silicon (purity ≥98.0%), Al-50Cu, Al-10Ni, industrial pure magnesium (purity ≥99.8%) ), Al-10Sr, Al-10RE, in the Al-10RE, RE is a mixed rare earth, and (La+Ce)% in the mixed rare earth is ≥ 99.6%;

[0054] Quantitative ingredients are calculated based on the target composition of aluminum-silicon alloy and element burnout rate, among which, the element burnout rate is as follow...

Embodiment 3

[0065] An aluminum-silicon alloy for a cylinder liner, the components and mass percentages of the aluminum-silicon alloy are as follows: Si: 15%, Cu: 1%, Ni: 2.5%, Mg: 2.5%, Sr: 0.01%, mixed rare earth elements RE: 0.5%, impurity elements: less than 1%, the balance is Al, and the sum of the total amount of each component is 100%.

[0066] The preparation process of the aluminum-silicon alloy for the above-mentioned cylinder liner:

[0067] 1) The target composition of aluminum-silicon alloy is quantitatively dosed with the following raw materials: industrial pure aluminum (purity ≥99.0%), industrial pure silicon (purity ≥98.0%), Al-50Cu, Al-10Ni, industrial pure magnesium (purity ≥99.8%) ), Al-10Sr, Al-10RE, in the Al-10RE, RE is a mixed rare earth, and (La+Ce)% in the mixed rare earth is ≥ 99.6%;

[0068] Quantitative ingredients are calculated based on the target composition of aluminum-silicon alloy and element burnout rate, among which, the element burnout rate is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com