Intelligent remote control type Chinese chive harvesting bundling machine

An intelligent remote control and strapping machine technology, which is applied in the direction of cutting and bundling machines, harvesters, agricultural machinery and implements, etc., can solve the problems that the degree of automation cannot meet the actual needs, and the efficiency of harvesting and bundling operations has not been really improved, so as to reduce manual labor. The number of operations, the effect of improving the production environment and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

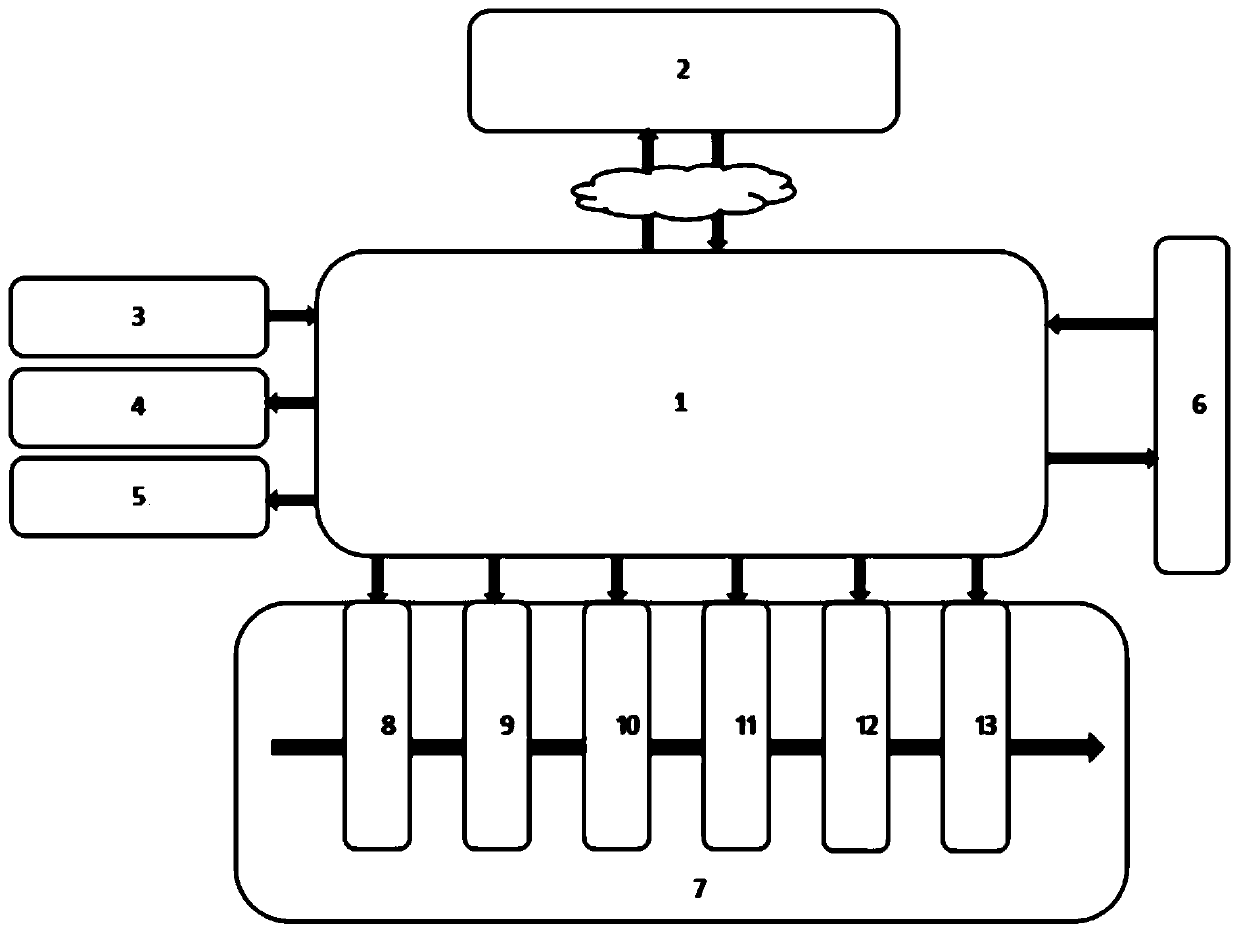

[0044] In order to solve the various problems faced by the harvesting and bundling of leeks in the greenhouse mentioned in the background art, the harvesting and bundling of leeks can be realized simply and quickly, liberating people from the narrow working space, and thus developed this product. The device of this invention mainly includes:

[0045] 1. The car body operating device, its component functions and operating procedures are:

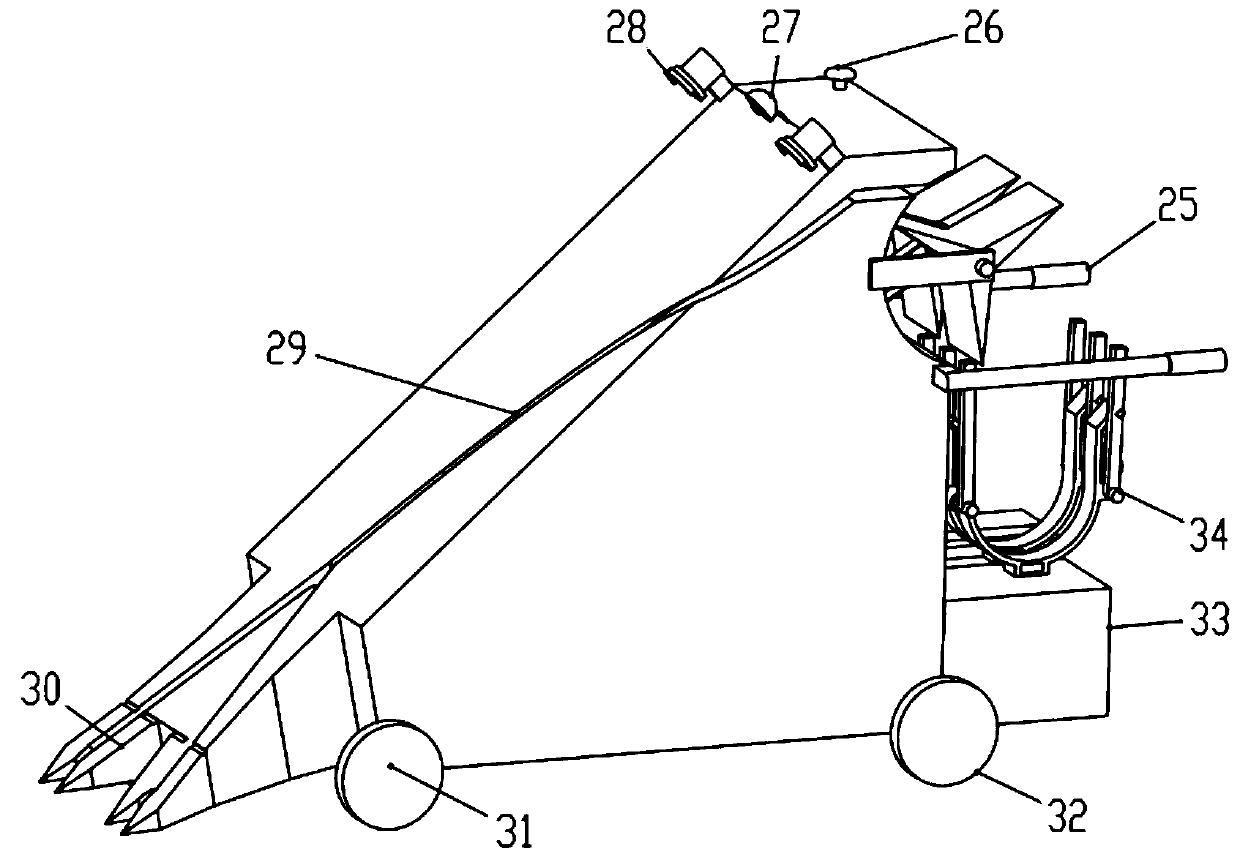

[0046] (1) The gathering device in the vehicle body operating device adopts the oblate cone-shaped device commonly used at the front end of the crop harvester to separate the crops by ridges, and the gathering device gathers the leeks to be harvested to the harvesting cutter.

[0047] (2) Cut the leeks with a harvesting knife close to the ground.

[0048] (3) The fluff conveyor belt 56 is specially designed by the present invention to realize the neat and intact transmission of leek, see Figure 7 , The surface of the fluff conveyor belt 56 has a 10m...

Embodiment 2

[0070] The solution in Embodiment 1 will be further introduced below in conjunction with specific drawings and examples. For details, see the following description:

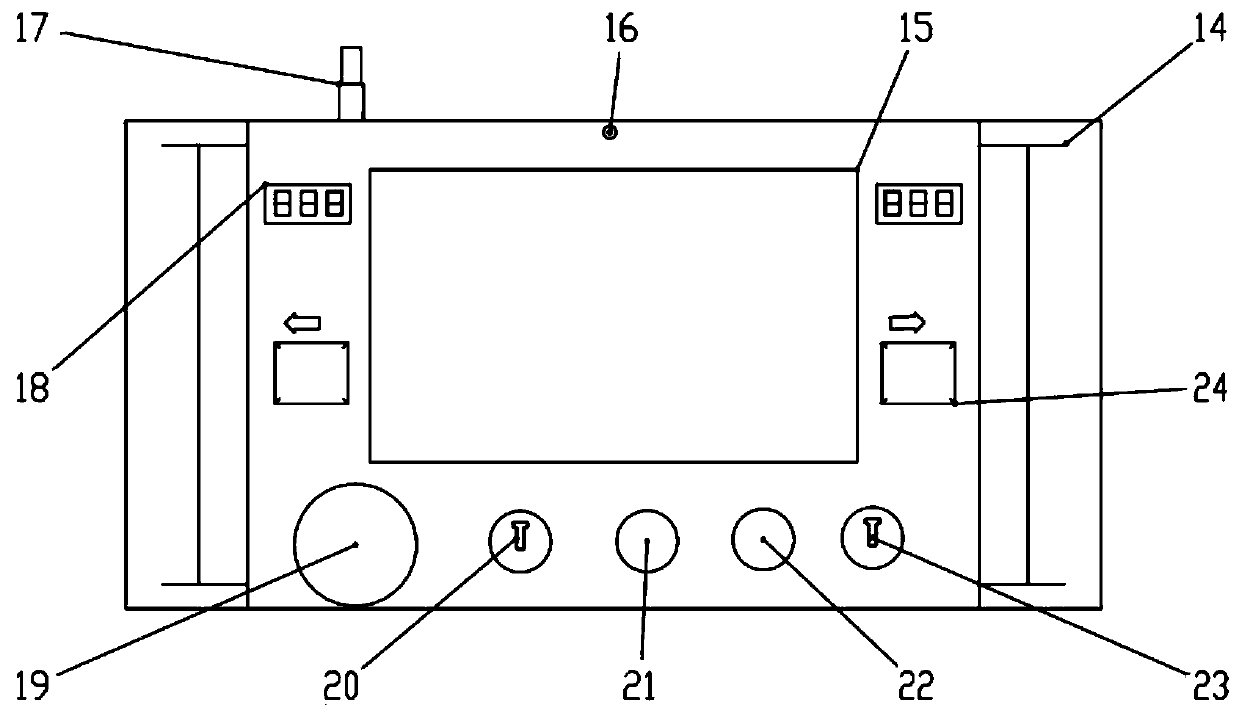

[0071] (1) The design of the remote control (such as figure 2 Shown):

[0072] figure 2 The device names and functions in are as follows:

[0073] Handle 14: One on each side, used to fix the remote control during operation.

[0074] LCD screen 15: The LCD screen comes with a wireless receiving module, which receives and displays the image signal from the camera of the car body.

[0075] Buzzer 16: Sound when a fault alarm occurs to remind the operator to deal with the alarm information.

[0076] Wireless module lead antenna 17: The remote control uses the wireless module to transmit control signals, and its antenna is lead out to the outside of the remote control.

[0077] Status digital display meter and power digital display meter 18: Two digital display meters controlled by I2C bus. The status digital display shows th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com