Assembly line and process for preparing Shiyang ferment tofu

An assembly line and tofu technology, which is applied in the field of food processing, can solve the problems that food safety cannot be guaranteed, it is difficult to adapt to industrialized production, and cannot meet the qualified standards, etc., and achieves the effects of food safety assurance, product quality stability, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

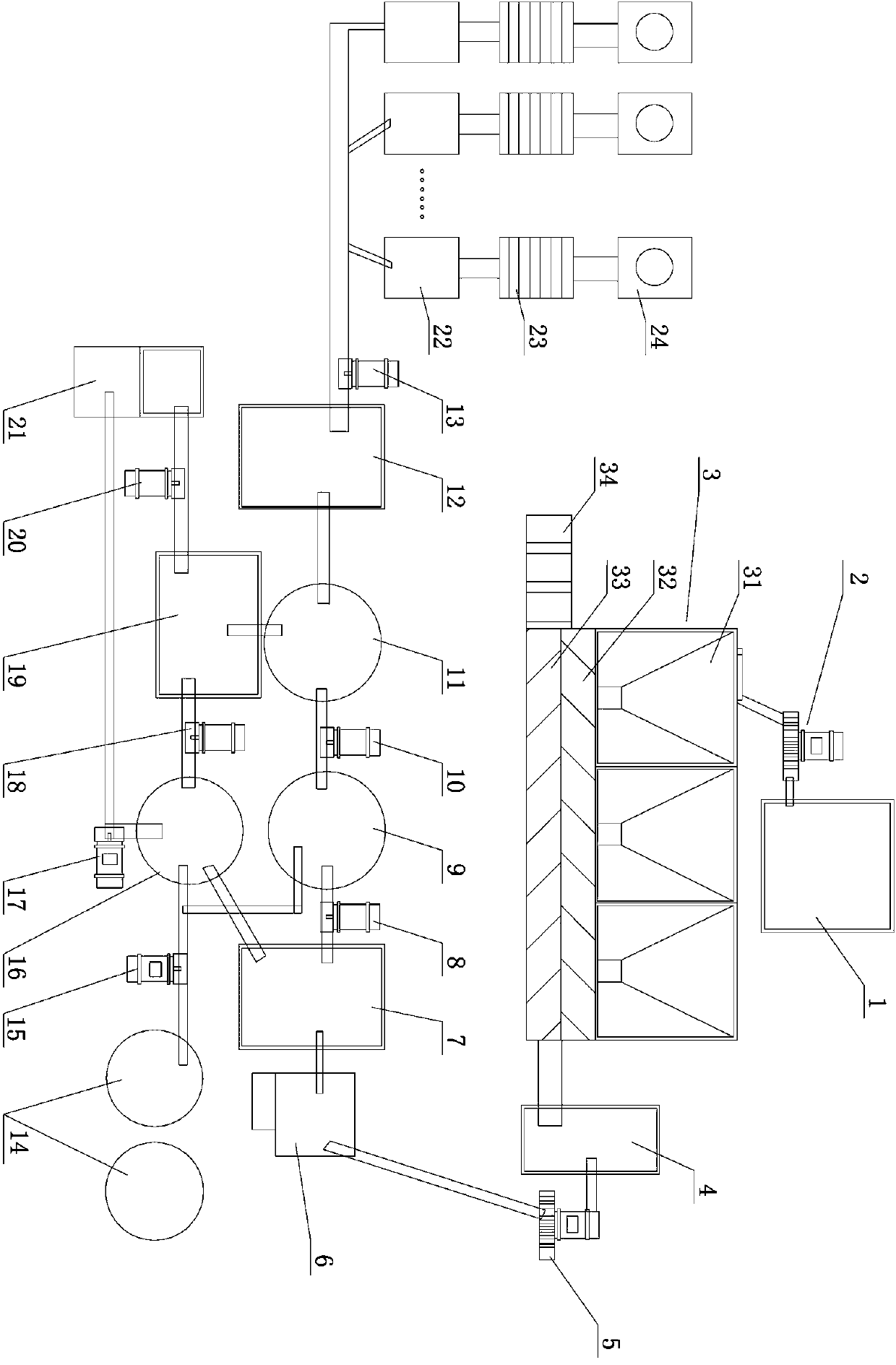

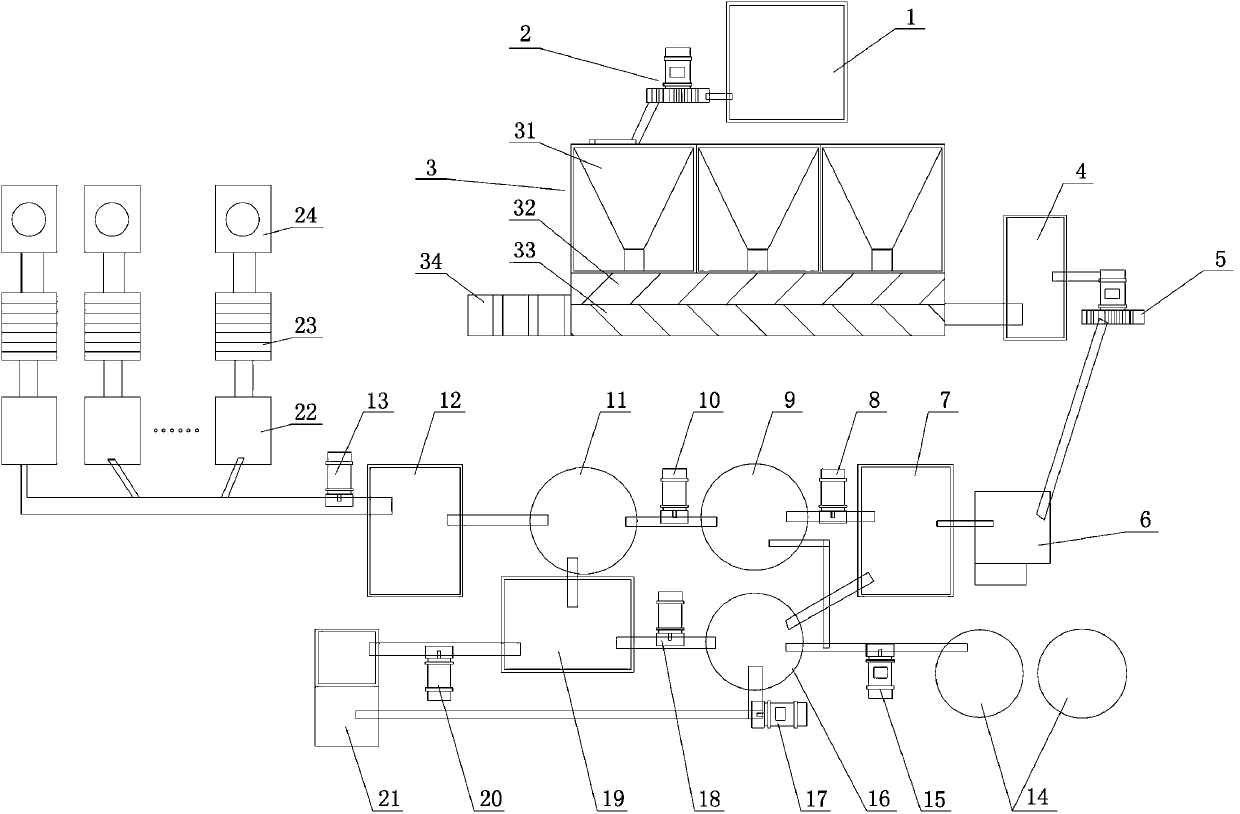

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] refer to figure 1 As shown, the present invention discloses an assembly line for preparing Shiyang fermented bean curd, which comprises soaking and washing equipment 3, a wet bean pool 4, a first grinder 6, a first slurry pool 7, a first Stirring barrel 9, vibrating screen 11, slurry storage tank 12, point slurry pot 22, tofu pressing equipment 23 and fried tofu equipment 24;

[0031] Between the wet bean pool 4 and the first grinder 6, between the first slurry pool 7 and the first mixing tank 9, between the first mixing tank 9 and the vibrating screen 11, and between the slurry storage tank 12 and the point The second conveying equipment 5, the third conveying equipment 8, the fourth conveying equipment 10 and the fifth conveying equipment 13 are respectively arranged between the slurry pans 22;

[0032] Above the soaking and bean washing equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com