Composition containing polypropylene homopolymer, polypropylene material and preparation method and application of polypropylene homopolymer material

A technology of polypropylene homopolymer and composition, which is applied in the field of polyolefin materials, can solve the problems of poor gloss and optical performance, fast corona attenuation, and not easy to corona, etc., and achieve good optical performance and improved corona performance , The effect of reducing processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

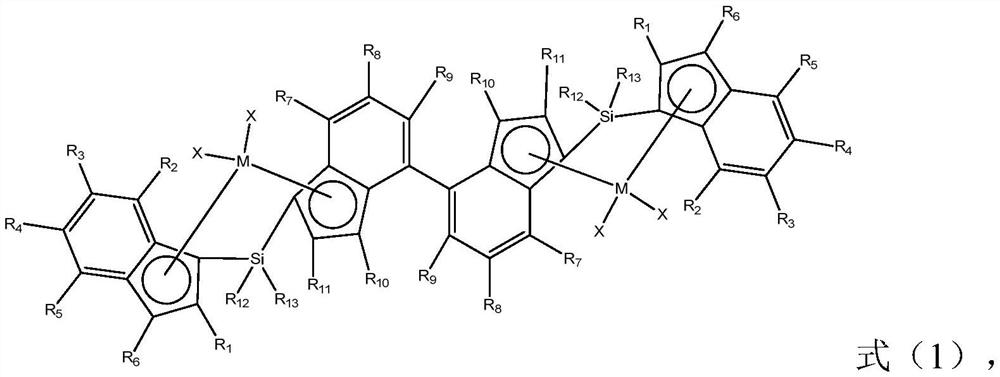

[0041] In the formula (1), two m is the same, and Ti, Zr or HF;

[0042] Each X is the same, and is fluorine, chlorine or bromine;

[0043] Rim 1 R 2 R 3 R 4 R 7 R 8 R 9 R 11 Each independently h, substituted or unsubstituted C 1 -C 4 Alkyl, substituted or unsubstituted C 2 -C 4 Alkenyl, substituted or unsubstituted C 7 -C 20 Aralkyl, substituted or unsubstituted C 6 -C 20 Aryl;

[0044] Rim 1 R 2 R 3 R 4 R 7 R 8 R 9 R 11 The substituents existing in the present are independently selected from C. 1 -C 4 At least one of the alkyl group;

[0045] Rim 12 R 13 Each is independently H, methyl or ethyl;

[0046] Rim 5 Phenyl;

[0047] Rim 6 R 10 All are hydrogen.

specific Embodiment approach 2

[0048] In the formula (1), two m is the same, and Ti, Zr or HF;

[0049] Each X is the same, and it is chlorine;

[0050] Rim 1 R 11 Both are methyl;

[0051] Rim 2 R 3 R 4 R 6 R 7 R 8 R 9 R 10 Both H;

[0052] Rim 5 Phenyl;

[0053] Rim 12 R 13 Each is independently H, methyl or ethyl.

specific Embodiment approach 3

[0054] In the formula (1), two m is the same, and Ti, Zr or HF;

[0055] Each X is the same, and it is chlorine;

[0056] Rim 1 R 11 Both are methyl;

[0057] Rim 2 R 3 R 4 R 6 R 7 R 8 R 9 R 10 Both H;

[0058] Rim 5 Phenyl;

[0059] Rim 12 R 13 All are methyl.

[0060] In order to achieve a low crystallinity of homopolymer, a better effect of low melting point, preferably, the polypropylene homopolymer exists 2,1-insert. This 2,1-insert can pass the nuclear magnetic detection.

[0061] Preferably, the melting temperature of the polypropylene homopolymer is less than or equal to 155 ° C, more preferably, the melting temperature of the polypropylene homopolymer is less than or equal to 151 ° C.

[0062] Preferably, the melt mass flow rate (230 ° C, 2.16 kg) of the polypropylene homopolymer is 4-10 g / 10 min; more preferably, the melt mass flow rate of the polypropylene homopolymer (230 ° C) 2.16kg) is 6-9 g / 10 min.

[0063] In a preferred embodiment, the content of the antioxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com