3D printing lightweight lattice structure and shoe sole adopting structure

A 3D printing, lattice structure technology, applied in shoe soles, applications, footwear and other directions, can solve the problems of irreplaceable, limited 3D printing raw materials, high 3D printing cost, and achieve good mechanical stability and aesthetics, Material saving, highly repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

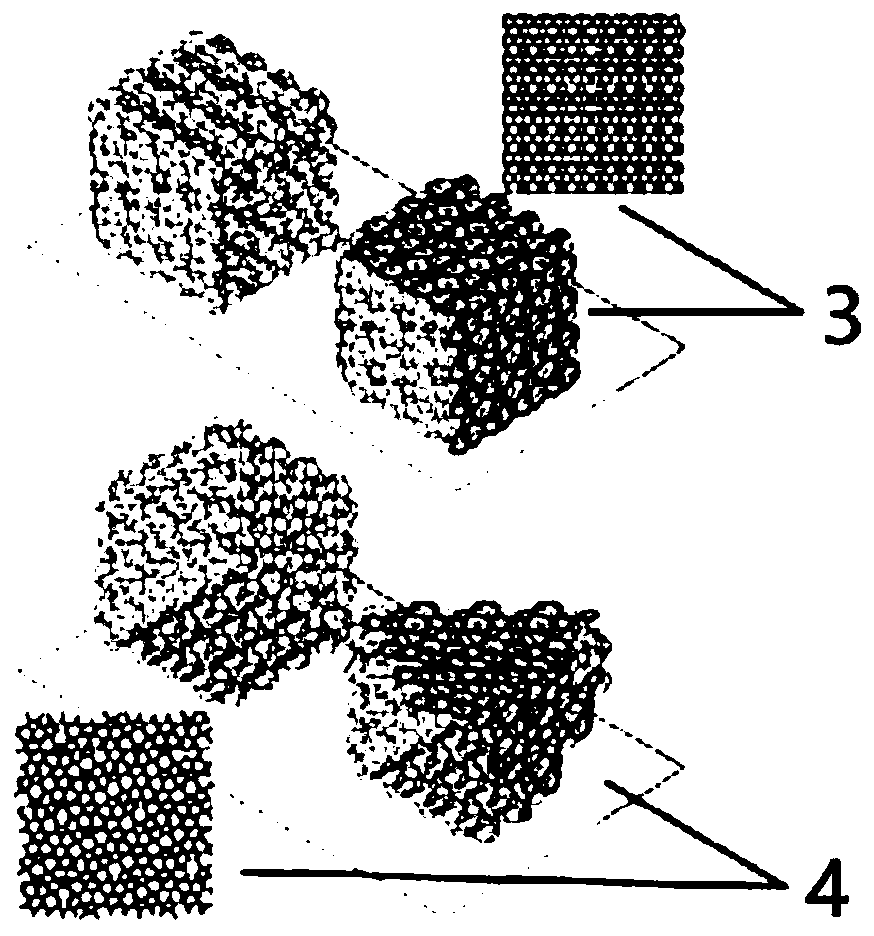

[0039] Such as image 3 , Figure 4 As shown, use computer 3D design software to carry out 3D lightweight structure samples or 3D digital modeling of shoe soles, import 3D lightweight structure samples or 3D digital models of shoe soles into a 3D printer to print.

[0040] 3D lightweight structural samples or sole 3D printers use SLS selective laser sintering printers.

[0041] 3D lightweight structural sample or shoe sole 3D printing uses SLS selective laser sintering technology, the printing raw material is TPU powder (or nylon powder), and the laser is used to scan and irradiate the powder layer by layer under the control of the computer to realize the sintering and bonding of TPU powder. Combined, layer upon layer to achieve molding.

[0042]The TPU powder used in the 3D printing sole is a powder with a particle size of 100 microns, and its sintering temperature is 160°. The particle size and molding temperature of the above-mentioned TPU powder are all possible in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com