Cable-free linear motor feeding system

A linear motor and feed system technology, applied in metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of limiting the running speed and positioning accuracy of the system, and improve the running speed and positioning accuracy. , The effect of preventing pollution and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

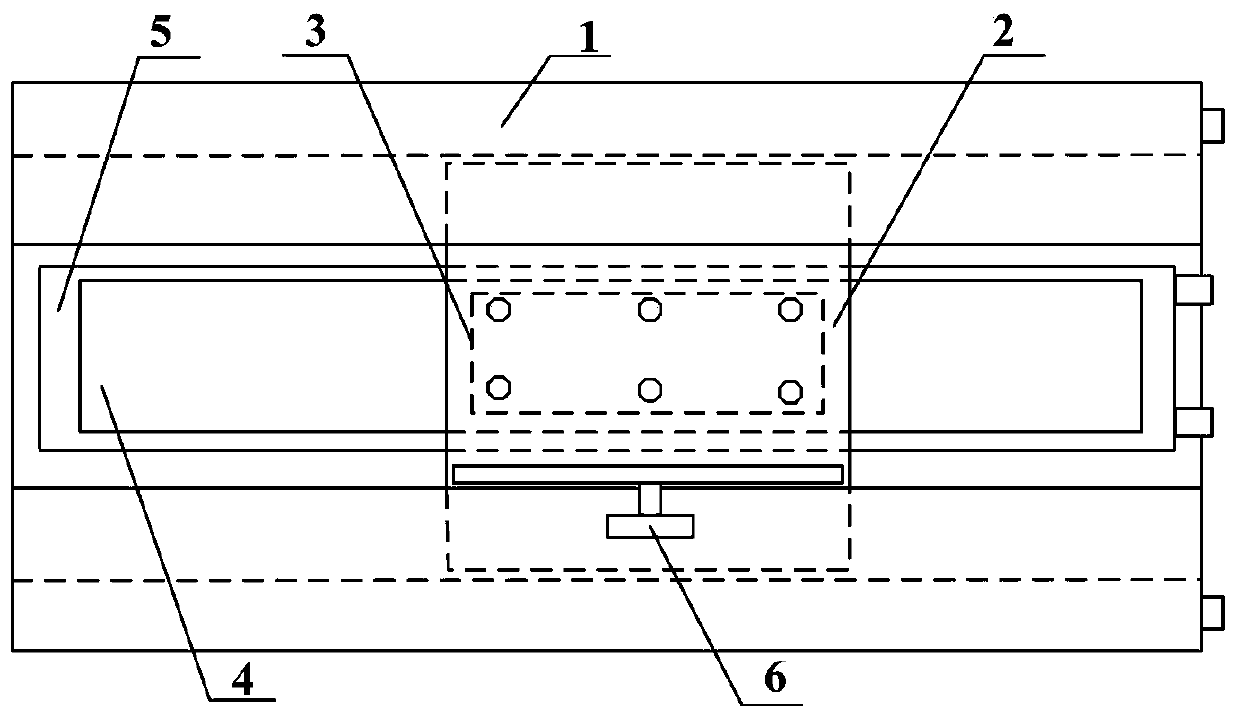

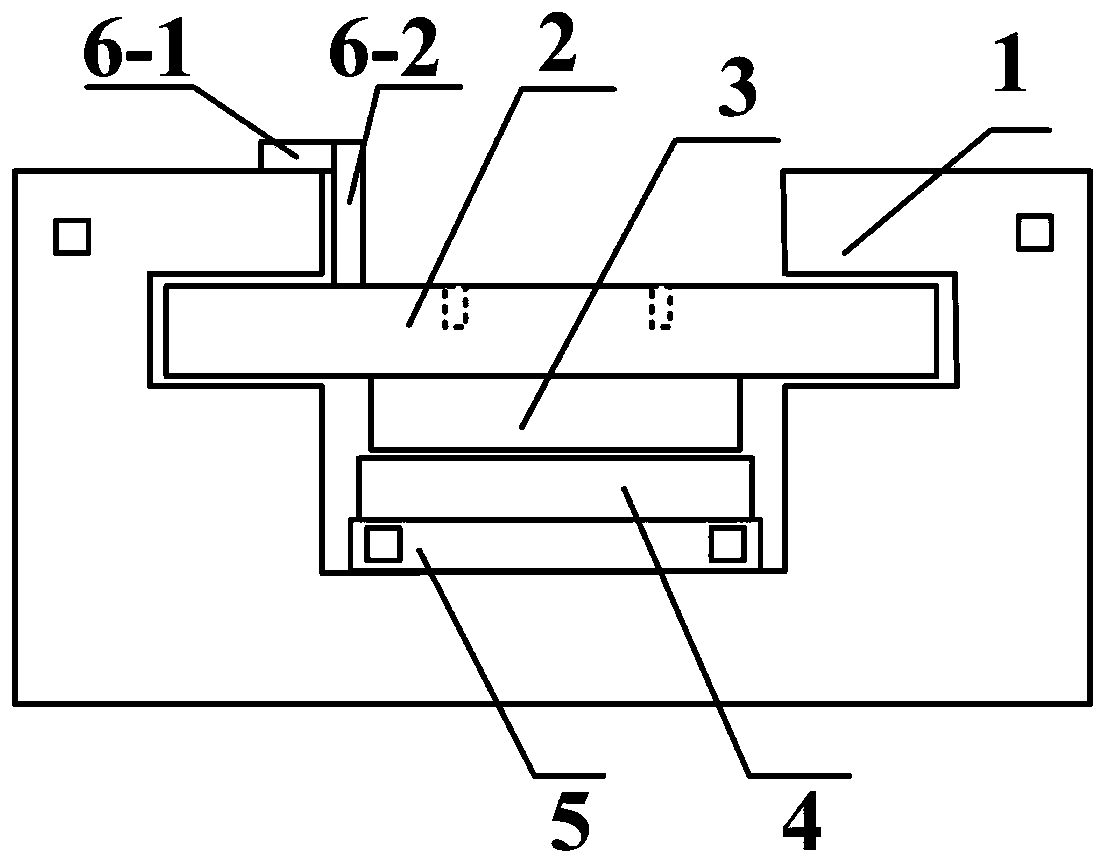

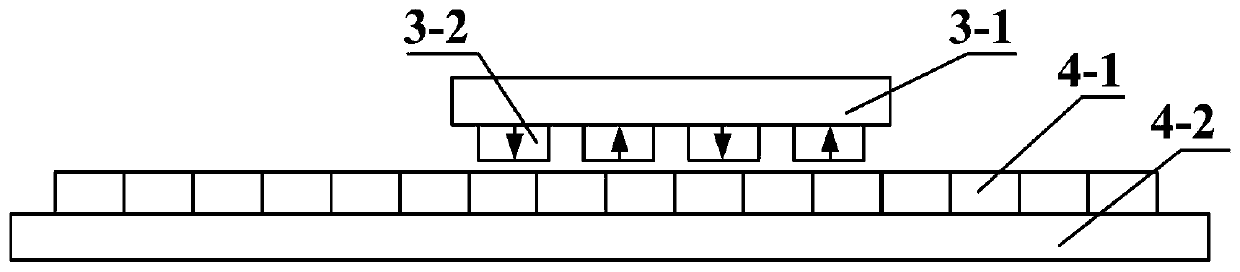

[0029] Such as figure 1 As shown, the cable-free linear motor feeding system includes a marble base 1, a load assembly 2, a linear motor mover 3, a linear motor stator 4, a water cooling plate 5, a position signal detection assembly 6 and a controller.

[0030] The marble base 1 has a main groove and a side groove, and the side groove is used as an air bearing guide rail to support the movement of the load assembly 2, and the three surfaces of the side groove are provided with throttle holes, such as Figure 4 shown. Anti-collision buffer pieces are installed at both ends of the side slot. The load assembly 2 is also made of marble, and is inserted longitudinally into the side groove of the marble base. There are 6 threaded holes on the upper surface of the load component 2 for connecting with the load. A protective cover can be installed on the upper surface of the load assembly to prevent waste chips from production and processing from entering the air flotation working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com