Mechanical arm force feedback control system and method based on embedded type motion controller

A feedback control system and motion control technology, applied in the field of robotic arm control, can solve problems such as lack of external perception functions, achieve good real-time performance, low development and manufacturing costs, and reduce system complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

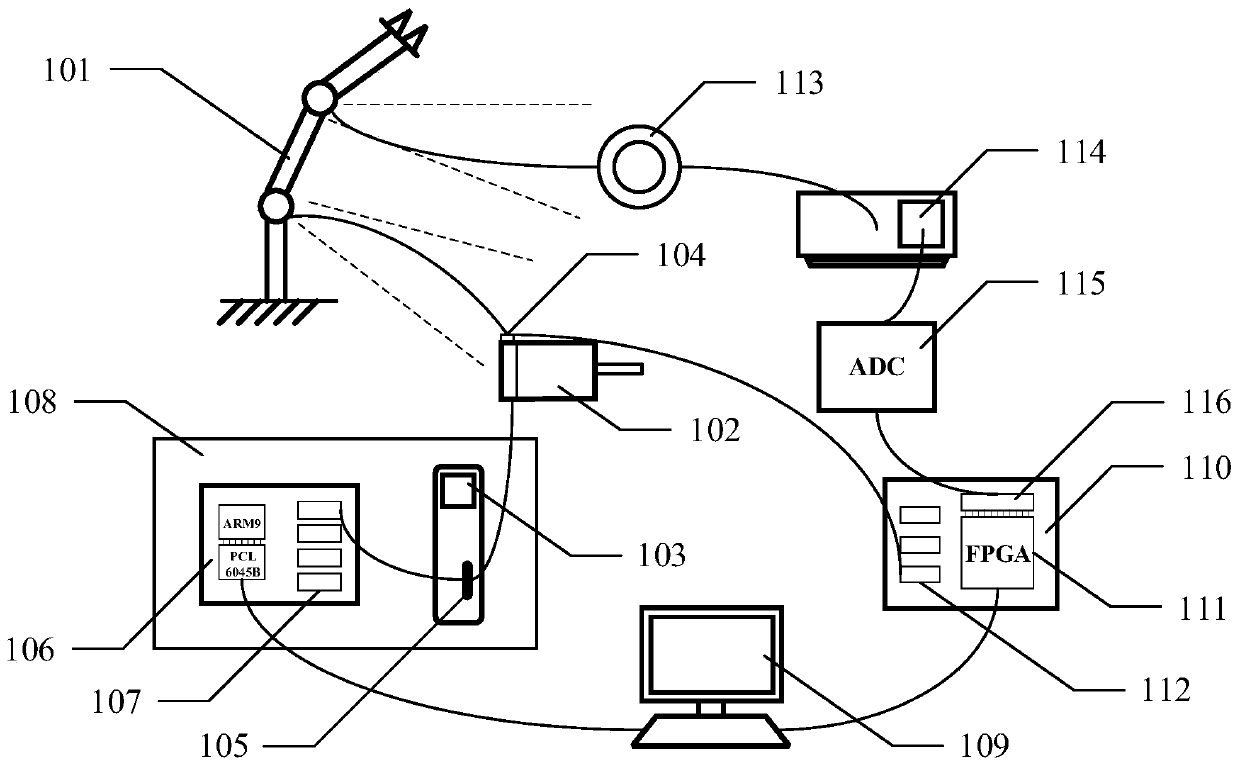

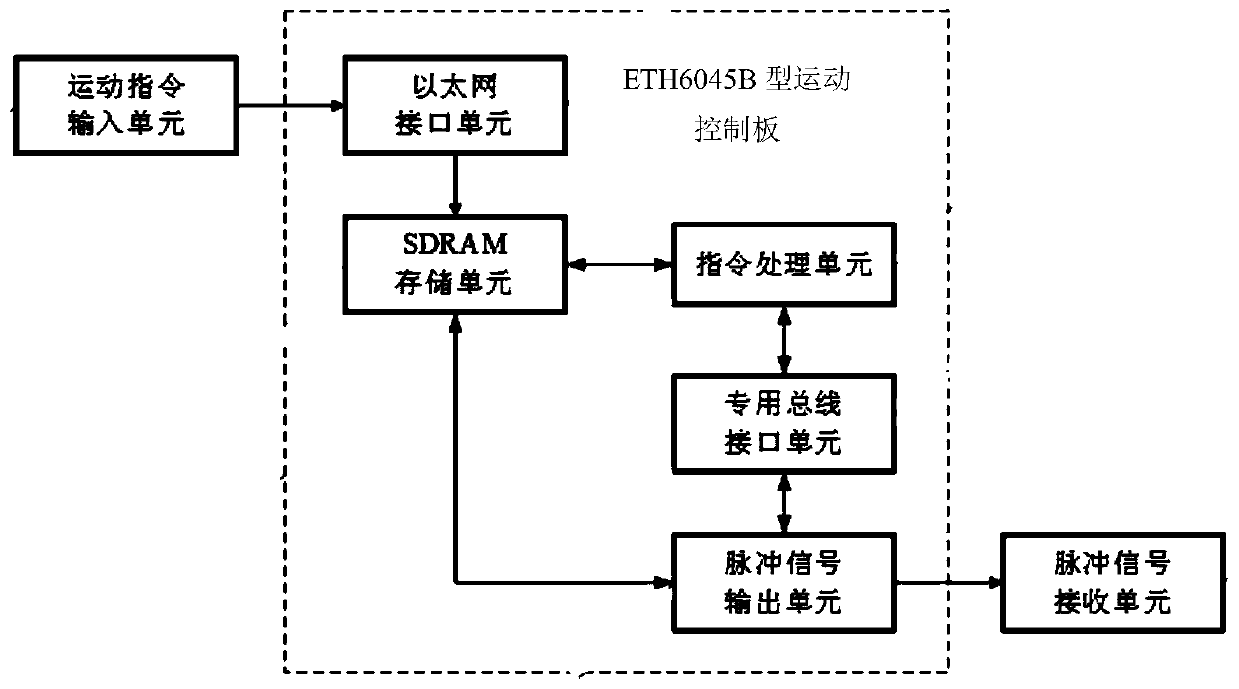

[0031] Such as figure 1As shown, a mechanical arm force feedback control system based on an embedded motion controller includes a six-axis lightweight mechanical arm body 101, a servo motor 102, a servo motor driver 103, a servo motor encoder 104, and an embedded ETH6045B type Type motion control board 106, mechanical arm control electrical cabinet 108, upper computer 109, FPGA adapter board 110, strain type spoke sensor 113, resistance strain gauge 114, ADC analog-to-digital converter 115. The servo motor 102 and the strain gauge spoke sensor 113 are respectively installed at each joint of the six-axis lightweight mechanical arm body 101; the servo motor encoder 104 is connected to the servo motor driver 103 with a special cable; ARM9 chip, PCL604...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com