rear control arm structure

A control arm and structure technology, which is applied to the cantilever mounted on the pivot, vehicle parts, transportation and packaging, etc., can solve the problem of increased stamping, welding and other manufacturing processes, weak strength and rigidity of the rear control arm, and difficult reinforcement plate technology Forming and other issues, to achieve the effect of easy processing and manufacturing, lightweight design, improved structural strength, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

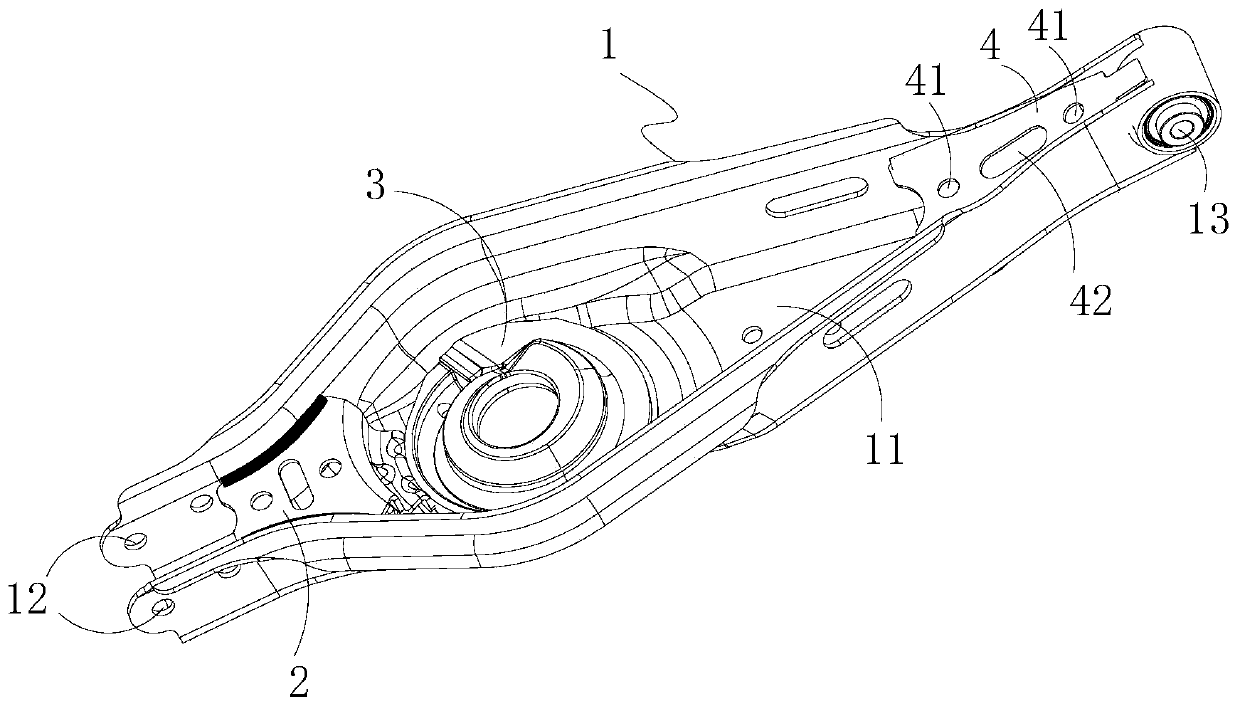

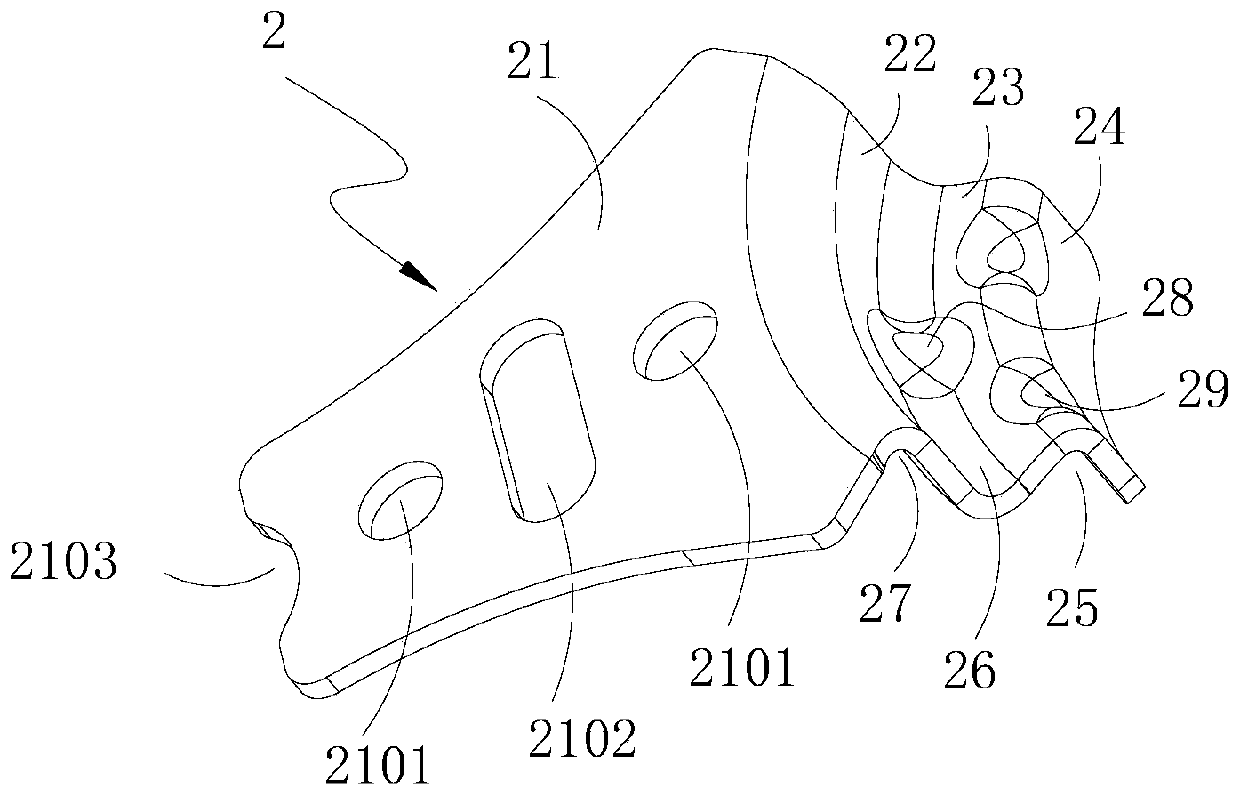

[0035] The invention relates to a structure of a rear control arm, which includes a control arm main body and a first reinforcement part, wherein, an accommodating cavity arranged along the length direction of the control arm main body is formed on the control arm main body, and a bottom of the accommodating cavity is configured for The installation part of the coil spring seat is installed; the first reinforcement part is accommodated in the accommodating cavity and is located on one side of the installation part, and the first reinforcement part is fixedly connected between the two side walls of the accommodating cavity to The side wall constitutes a rigidly supported reinforcing unit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com