Paste tile binder and preparation method thereof

A tile adhesive and paste-like technology, which is applied in the field of tile adhesives, can solve problems such as the weakening of the flexural strength of the adhesive, and achieve the effect of avoiding gel phenomenon and increasing the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

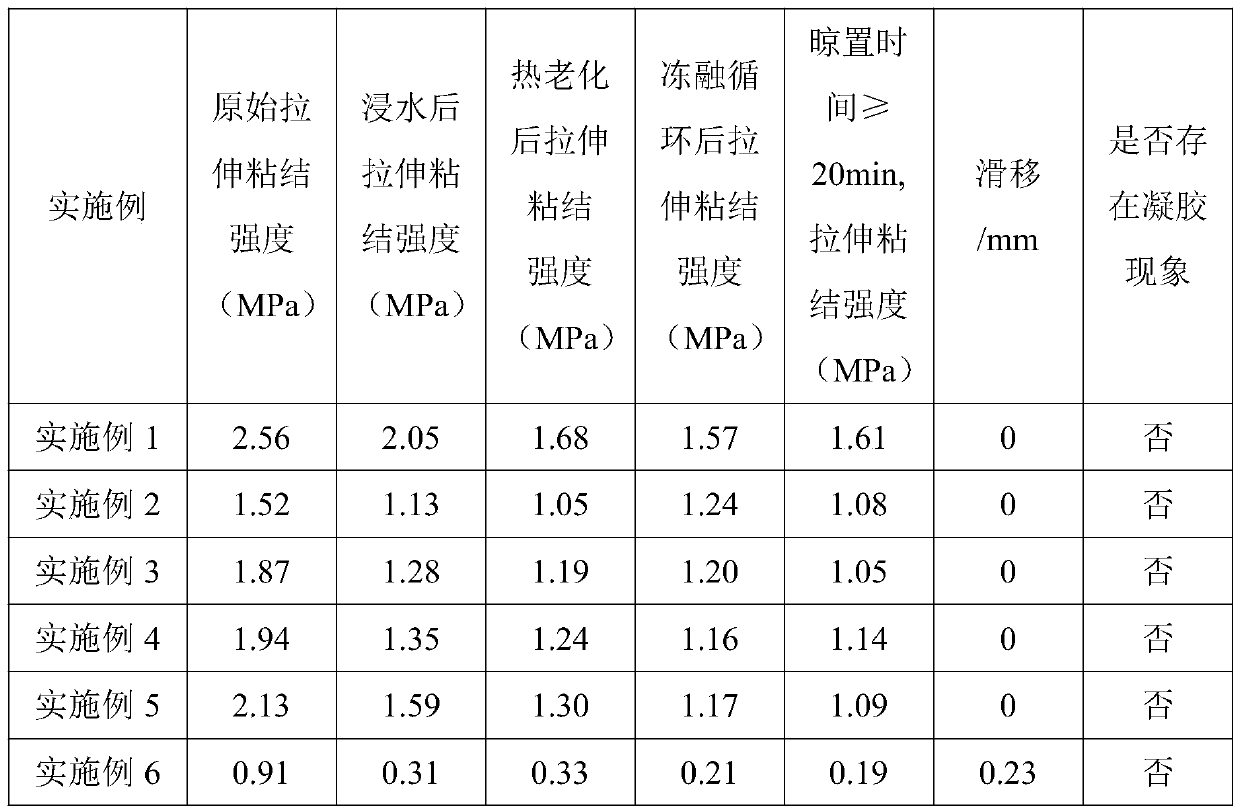

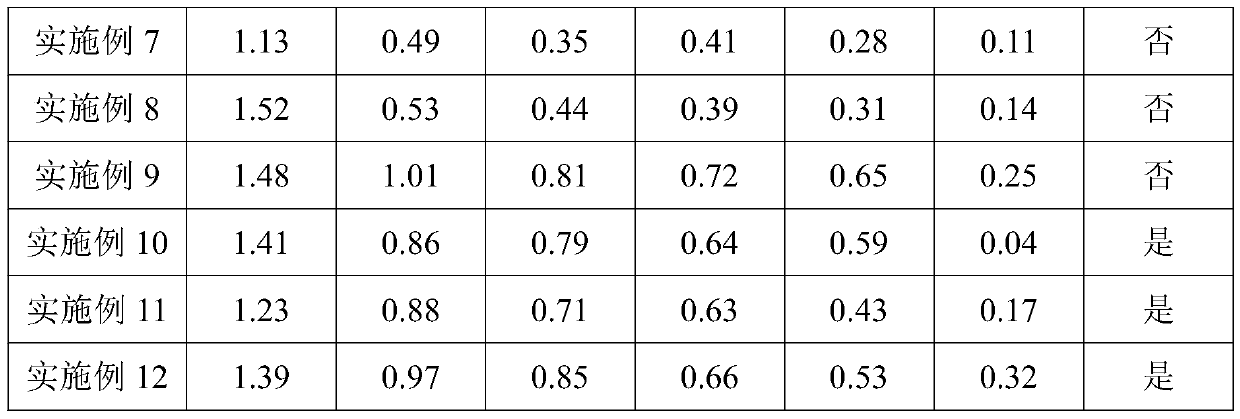

Examples

preparation example Construction

[0065] A second aspect of the present invention provides a method for preparing the paste tile adhesive, at least comprising the following steps:

[0066] (1) Add defoamer, film-forming aid, and cellulose ether into the solvent respectively, and stir for 5 to 10 minutes;

[0067] (2) Then add filler and quartz sand, stir for 15-30 minutes, then add emulsion, stir for 10-20 minutes;

[0068] (3) Finally, add butanol polyether, stir for another 15 to 30 minutes, and then fill it into a barrel to obtain the finished product.

[0069] In some preferred embodiments, the preparation method of the paste tile adhesive at least comprises the following steps:

[0070] (1) Add defoamer, film-forming aid, and cellulose ether into the solvent respectively, and stir for 7 to 9 minutes;

[0071] (2) Then add filler and quartz sand, stir for 17-19 minutes, then add emulsion, stir for 14-18 minutes;

[0072] (3) Finally, add butanol polyether, stir for another 20-26 minutes, and then fill i...

Embodiment 1

[0083] A kind of pasty ceramic tile adhesive, by weight, raw material comprises, 75 parts of emulsions, 180 parts of solvents, 3.5 parts of film-forming aids, 2 parts of defoamers, 5 parts of cellulose ethers, 1.3 parts of butanol polyethers , 350 parts of filler, 350 parts of quartz sand;

[0084] The preparation method of described paste tile adhesive, comprises the following steps:

[0085] (1) Add defoamer, film-forming aid, cellulose ether respectively in solvent, stir for 8 minutes;

[0086] (2) Then add filler and quartz sand, stir for 18 minutes, then add emulsion, stir for 16 minutes;

[0087] (3) Finally, add butanol, stir for another 23 minutes, and then fill it into a barrel to obtain the finished product;

[0088] The cellulose ether is cellulose ether modified fumed silica; the butanol is PPG-26-butanol-26; the emulsion is a styrene-acrylate emulsion, purchased from Guangzhou Zhen Cheng Chemical Co., Ltd., the brand is ECO 338; the solvent is deionized water; ...

Embodiment 2

[0090] A paste-like tile adhesive, the raw materials include at least 50 parts of emulsion, 100 parts of solvent, 1 part of film-forming aid, 0.5 part of defoamer, 1 part of cellulose ether, and 0.1 part of butanol by weight. Ether, 300 parts of filler, 300 parts of quartz sand;

[0091] The preparation method of described paste tile adhesive, at least comprises the following steps:

[0092] (1) Add defoamer, film-forming aid, cellulose ether respectively in solvent, stir for 5 minutes;

[0093] (2) Then add filler and quartz sand, stir for 15 minutes, then add emulsion, stir for 10 minutes;

[0094] (3) Finally add butanol polyether, stir for another 15 minutes, and then fill it into a barrel to obtain the finished product;

[0095]The cellulose ether is cellulose ether modified fumed silica; the butanol polyether is PPG-26-butanol-26; the emulsion is pure acrylic emulsion, S-05 pure acrylic emulsion, purchased From Nantong Shengda Chemical Co., Ltd.; the solvent is deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com