Preparing method for high-strength temperature-resistant organic silicon material

A silicone and temperature-resistant technology, which is applied in the field of preparation of silicone materials and high-strength temperature-resistant silicone materials, can solve the problems of poor stability of modified silicone and easy cracks, etc. Effects of hydrolysis change, improvement of strength and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

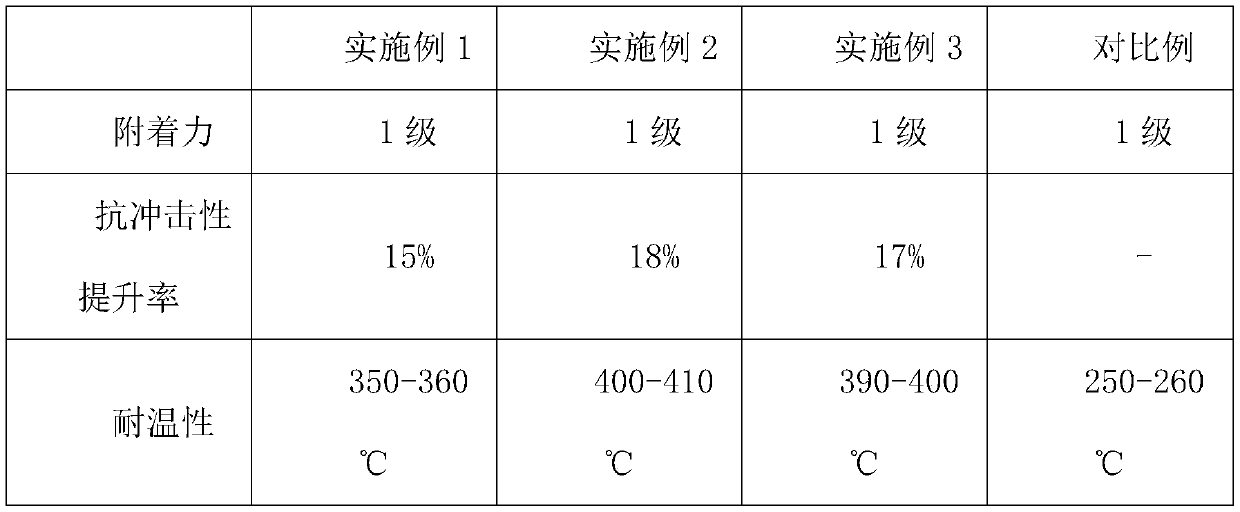

Examples

Embodiment 1

[0032] A method for preparing a high-strength temperature-resistant silicone material, comprising the steps of:

[0033] Step 1, add the volcanic stone to absolute ethanol for gradient ultrasonic cleaning, take it out and quickly dry it to obtain clean volcanic stone;

[0034] Step 2, adding clean volcanic stones into the ball mill, and then adding absolute ethanol to carry out ball milling reaction to obtain volcanic stone particles;

[0035] Step 3, adding phenyltrichlorosilane to the diethyl ether solution and stirring at a constant temperature until it is completely dissolved to obtain a diethyl ether solution, then adding distilled water dropwise and stirring evenly, and standing for constant temperature reaction for 2 hours to obtain a phenyltrichlorosilane hydrolyzate;

[0036] Step 4, putting the volcanic stone particles into the phenyltrichlorosilane hydrolyzate, adding a dispersant, stirring evenly, and filtering to obtain pre-coated volcanic stone particles;

[003...

Embodiment 2

[0048] A method for preparing a high-strength temperature-resistant silicone material, comprising the steps of:

[0049] Step 1, add the volcanic stone to absolute ethanol for gradient ultrasonic cleaning, take it out and quickly dry it to obtain clean volcanic stone;

[0050] Step 2, adding clean volcanic stones into the ball mill, and then adding absolute ethanol to carry out ball milling reaction to obtain volcanic stone particles;

[0051] Step 3, adding phenyltrichlorosilane to the diethyl ether solution and stirring at a constant temperature until it is completely dissolved to obtain a diethyl ether solution;

[0052] Step 4, putting the volcanic stone particles into the phenyltrichlorosilane hydrolyzate, adding a dispersant, stirring evenly, and filtering to obtain pre-coated volcanic stone particles;

[0053] Step 5, put the pre-coated volcanic stone particles into the reaction kettle to seal and react for 2 hours, and after releasing the pressure, raise the temperatu...

Embodiment 3

[0064] A method for preparing a high-strength temperature-resistant silicone material, comprising the steps of:

[0065] Step 1, add the volcanic stone to absolute ethanol for gradient ultrasonic cleaning, take it out and quickly dry it to obtain clean volcanic stone;

[0066] Step 2, adding clean volcanic stones into the ball mill, and then adding absolute ethanol to carry out ball milling reaction to obtain volcanic stone particles;

[0067] Step 3, adding phenyltrichlorosilane to the diethyl ether solution and stirring at a constant temperature until it is completely dissolved to obtain a diethyl ether solution, then adding distilled water dropwise and stirring evenly, and standing for constant temperature reaction for 3 hours to obtain a phenyltrichlorosilane hydrolyzate;

[0068] Step 4, putting the volcanic stone particles into the phenyltrichlorosilane hydrolyzate, adding a dispersant, stirring evenly, and filtering to obtain pre-coated volcanic stone particles;

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com