Environment-friendly hydrophobic paint

A hydrophobic coating and hydrophobic filler technology, applied in the direction of coating, etc., can solve the problems of coating peeling, economic loss, waste of resources, etc., and achieve the effects of improved stability, wide sources, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

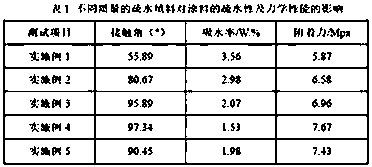

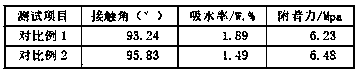

Examples

Embodiment 1

[0025] 75 ml of distilled water and 75 g of acrylic resin were blended at a speed of 300 r / min and mechanically stirred for 5 min to obtain a common paint.

Embodiment 2

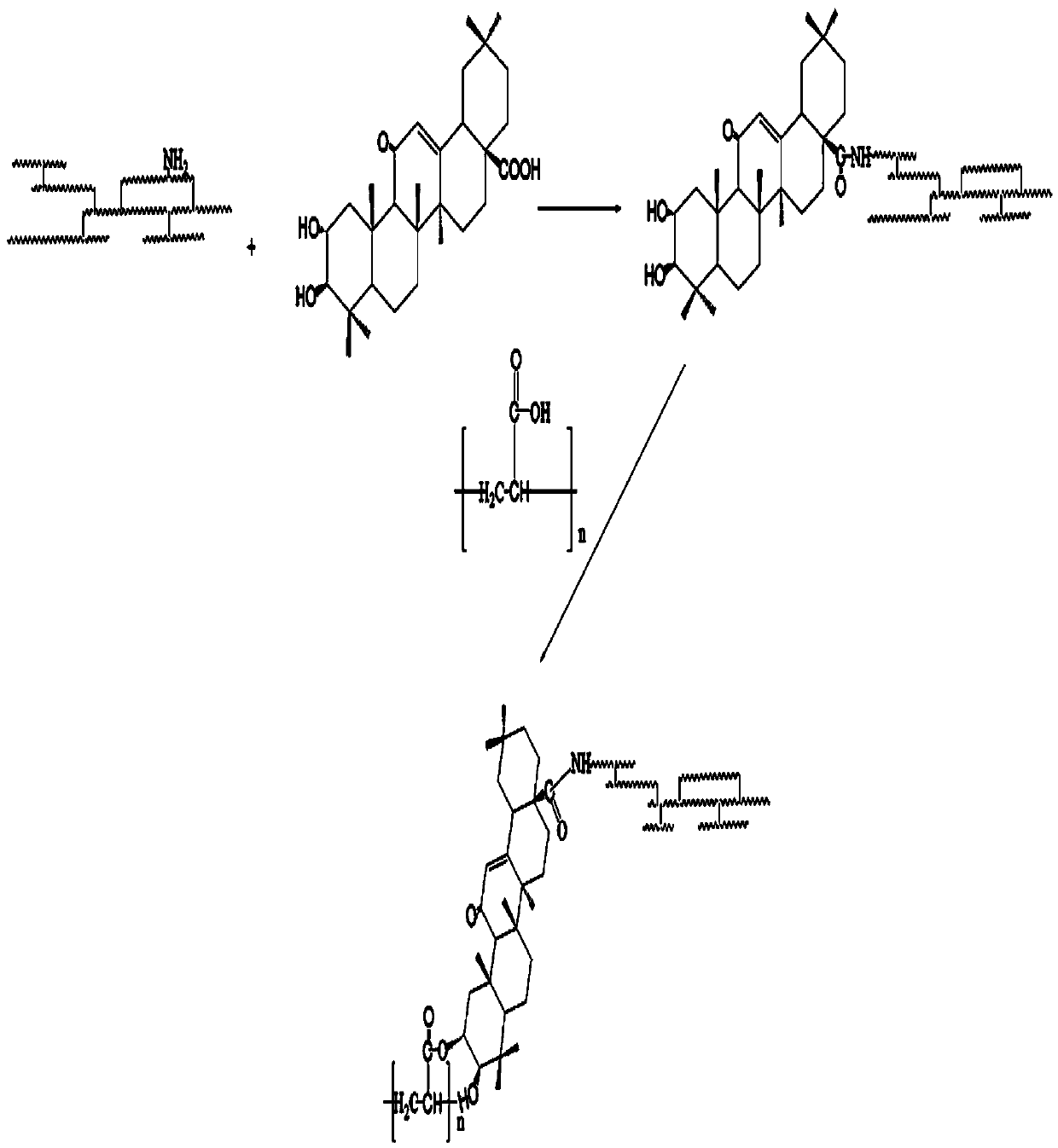

[0027] A method for preparing an environmentally friendly hydrophobic coating, characterized in that the coating is composed of oleanolic acid derivatives connected with elastin polypeptide biomacromolecules through chemical bonds and then compounded with acrylic resin, specifically synthesized Proceed as follows.

[0028] (1) Preparation of hydrophobic filler.

[0029] (a) Add 8 g of oleanolic acid derivatives, 10 g of peptide biomacromolecule powder and 75 ml of ethanol into the three-neck flask under reflux conditions, the temperature is controlled at 15 °C, the speed is 200 r / min, and stirred for 25 min. Lower the temperature to 2 °C, rotate at 300 r / min, and stir for 40 min until the peptide biomacromolecule powder is completely dispersed in the solvent.

[0030] (b) Raise the temperature of the three-neck flask after the reaction in (a) to 20 °C, rotate at 300 r / min, stir for 3 h, add 5 g of NaCl and continue stirring for 15 min to obtain a modified polypeptide hydrogel...

Embodiment 3

[0035] (1) Preparation of hydrophobic filler.

[0036] (a) Add 8 g of oleanolic acid derivatives, 10 g of peptide biomacromolecule powder and 75 ml of ethanol into the three-neck flask under reflux conditions, the temperature is controlled at 15 °C, the speed is 200 r / min, and stirred for 25 min. Lower the temperature to 2 °C, rotate at 300 r / min, and stir for 40 min until the peptide biomacromolecule powder is completely dispersed in the solvent.

[0037] (b) Raise the temperature of the three-neck flask after the reaction in (a) to 20 °C, rotate at 300 r / min, stir for 3 h, add 5 g of NaCl and continue stirring for 15 min to obtain a modified polypeptide hydrogel.

[0038] (c) The modified polypeptide hydrogel was freeze-dried at -20 °C for 9 h. After drying, it is ground in a mortar and sieved into powder with 200 meshes to obtain the hydrophobic filler.

[0039] (2) Preparation of environmentally friendly hydrophobic coatings.

[0040] 2.25 g of the hydrophobic filler pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com