A kind of automobile paint surface polishing agent and preparation method thereof

A polishing agent and paint surface technology, applied in the direction of surface polishing machine tools, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problem of unsatisfactory gloss and brightness Repair, manually adjust the strength and stabilize the polishing, etc., to achieve good and durable non-slip gloss, weaken ion adsorption, and eliminate oil-soluble impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

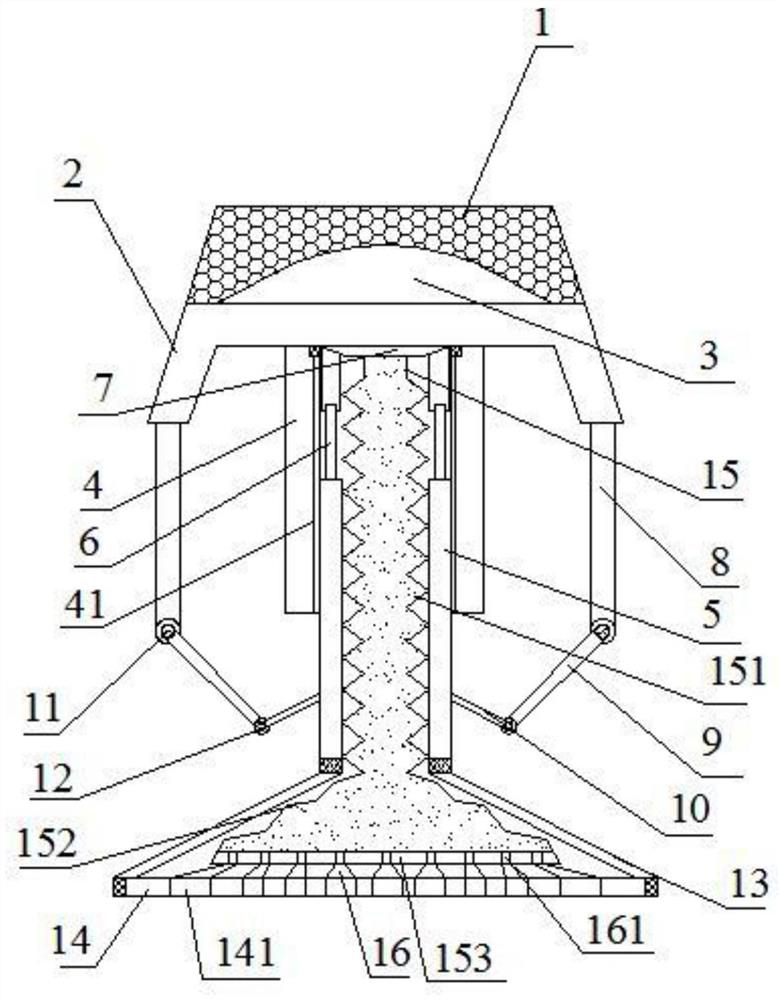

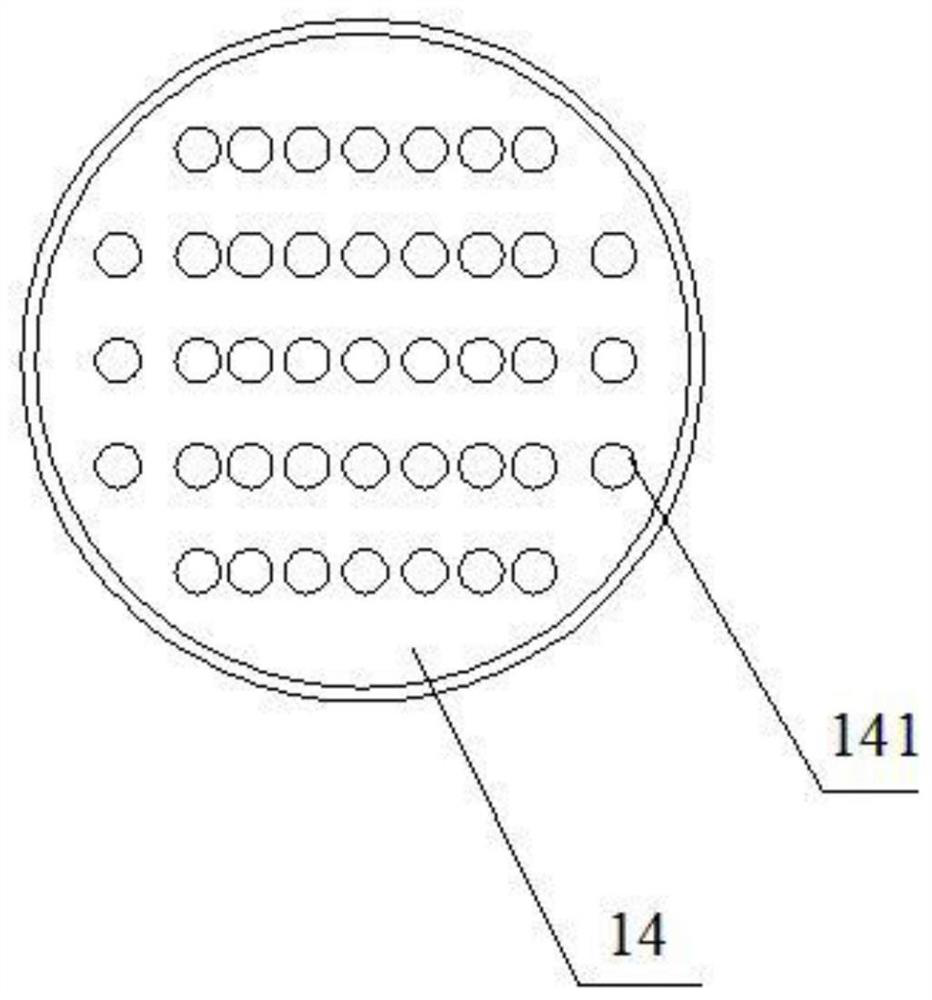

[0041] refer to Figure 1-2 As shown, a kind of automotive paint polishing agent of the present embodiment comprises the following raw materials in parts by weight, 18 parts of hydrophobic repairing abrasives, 15 parts of fatty alcohol polyoxyethylene ether, 9 parts of simethicone oil, 6 parts of sodium alginate, 4 parts of potassium sorbate, 2.8 parts of compound brightener, 76 parts of diluent. The diluent is made by mixing and stirring acetone, ethyl acetate, toluene, and cyclohexane according to the mass ratio of 3:2:1:1.

[0042] Wherein, the preparation method of hydrophobic repair abrasive comprises the following steps:

[0043] 1) In parts by weight, add 35 parts of mesoporous silica to 180 parts of deionized water, stir slowly for 16 minutes to obtain a mesoporous silica dispersion, raise the temperature to 115°C, add 20 parts of attapulgite, and vacuum- Stir at 0.15MPa for 25min to obtain a silica mixture;

[0044] 2) In parts by weight, 8 parts of multi-walled ca...

Embodiment 2

[0054] refer to Figure 1-2 As shown, a kind of automotive paint polishing agent of the present embodiment comprises the following raw materials in parts by weight, 22 parts of hydrophobic repairing abrasives, 18 parts of fatty alcohol polyoxyethylene ether, 10 parts of simethicone, 5 parts of sodium alginate, 4 parts of potassium sorbate, 2.5 parts of compound brightener, 75 parts of diluent. The diluent is made by mixing and stirring acetone, ethyl acetate, toluene, and cyclohexane according to the mass ratio of 3:2:1:1.

[0055] Wherein, the preparation method of hydrophobic repair abrasive comprises the following steps:

[0056] 1) In parts by weight, add 38 parts of mesoporous silica to 180 parts of deionized water, stir slowly for 18 minutes to obtain a mesoporous silica dispersion, raise the temperature to 120°C, add 18 parts of attapulgite, and vacuum- Stir at 0.2MPa for 30min to obtain a silica mixture;

[0057] 2) In parts by weight, 6 parts of multi-walled carbon...

Embodiment 3

[0067] refer to Figure 1-2 As shown, a kind of automotive paint polishing agent of the present embodiment includes the following raw materials in parts by weight, 20 parts of hydrophobic repairing abrasives, 20 parts of fatty alcohol polyoxyethylene ether, 11 parts of simethicone, 6 parts of sodium alginate, 4 parts of potassium sorbate, 2.8 parts of compound brightener, 80 parts of diluent. The diluent is made by mixing and stirring acetone, ethyl acetate, toluene, and cyclohexane according to the mass ratio of 3:2:1:1.

[0068] Wherein, the preparation method of hydrophobic repair abrasive comprises the following steps:

[0069] 1) In parts by weight, add 40 parts of mesoporous silica to 190 parts of deionized water, stir slowly for 20 minutes to obtain a mesoporous silica dispersion, raise the temperature to 120°C, add 22 parts of attapulgite, and vacuum- Stir at 0.2MPa for 26min to obtain a silica mixture;

[0070] 2) In parts by weight, 10 parts of multi-walled carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com