Preparation method for depositing cobalt on anodic aluminum oxide template

A technology of anodized aluminum and anodic oxidation, which is applied in the field of cobalt deposition, can solve the problems of less suitable anodic oxidation process, etc., and achieve the effect of improving fiber surface morphology, high stability, and easy deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

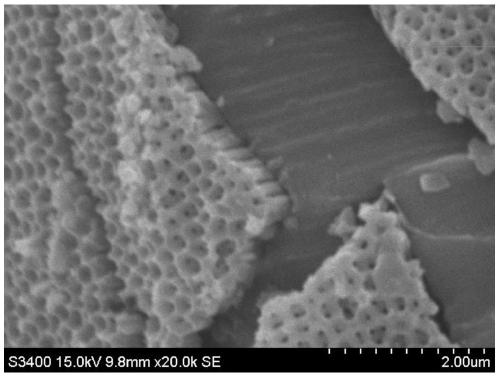

[0029] The preparation method of depositing cobalt on the anodized aluminum template of this embodiment is as follows:

[0030] (1) Pure aluminum surface pretreatment process: the pure aluminum material is cut, cleaned, degreased, and lye film removed in sequence;

[0031] (2) Put the pure aluminum pretreated in step (1) into the prepared malonic acid solution with a mass fraction of 1.0mol / L for anodic oxidation. The relevant parameters are time 4h, temperature 10°C, and voltage 140V;

[0032] (3) After anodized pure aluminum is depressurized to remove the barrier layer, it is rinsed with tap water, ultrasonically cleaned for 5 minutes, and then soaked in the film removal solution. The film removal solution is composed of phosphoric acid and chromium trioxide. Contains 10g of chromium trioxide, 10mL of phosphoric acid, the balance is water, soaking time 5h, temperature 60℃ for film removal treatment;

[0033] (4) After the aluminum sheet treated in step (3) is taken out, it ...

Embodiment 2

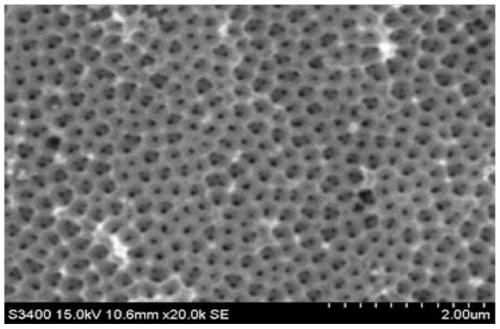

[0037] The preparation method of depositing cobalt on the anodized aluminum template of this embodiment is as follows:

[0038] (1) Pure aluminum surface pretreatment process: the pure aluminum material is cut, cleaned, degreased, and lye film removed in sequence;

[0039] (2) Put the pure aluminum pretreated in step (1) into the prepared malonic acid solution with a mass fraction of 1.0mol / L for anodic oxidation, and the relevant parameters are time 1h, temperature 20°C, and voltage 60V;

[0040] (3) After anodized pure aluminum is depressurized to remove the barrier layer, it is rinsed with tap water, ultrasonically cleaned for 5 minutes, and then soaked in the film removal solution. The film removal solution is composed of phosphoric acid and chromium trioxide. Contains 25g of chromium trioxide, 35mL of phosphoric acid, the balance is water, soaking time 6h, temperature 90℃ for film removal treatment;

[0041] (4) After the aluminum sheet treated in step (3) is taken out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com