Moist cross-linking organosilicone crease-resistant and easy-care finishing liquid and preparation method and application thereof

A non-iron finishing and organosilicon technology, applied in the field of textile printing and dyeing, can solve the problems of reduced hand comfort and strength, and achieve the effect of ensuring safety and environmental protection, ensuring whiteness, and achieving non-iron finishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

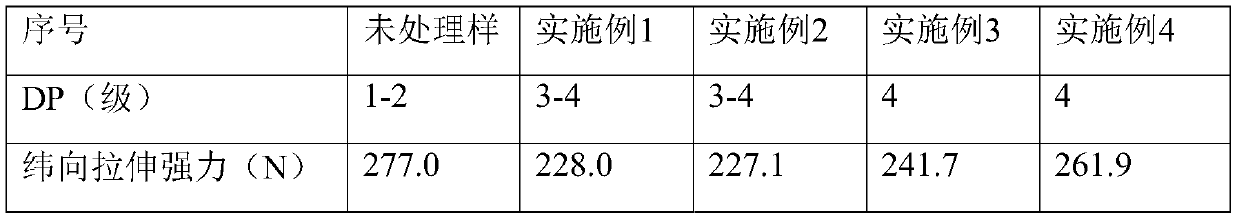

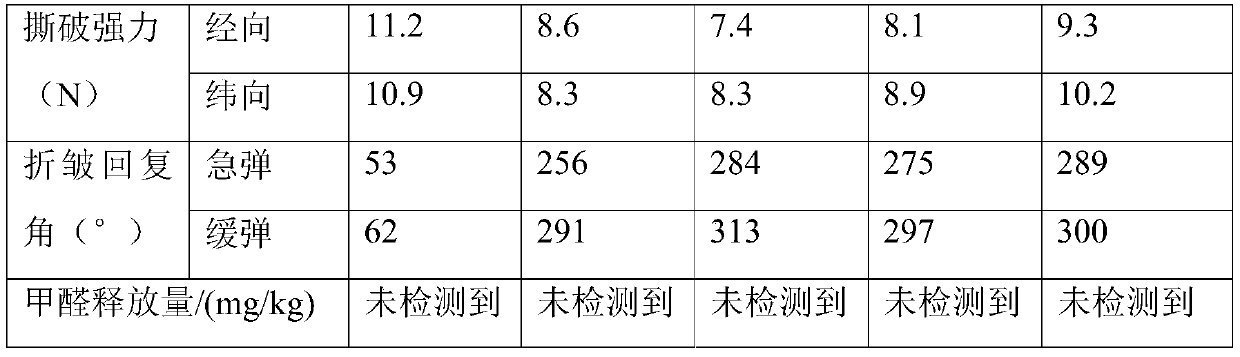

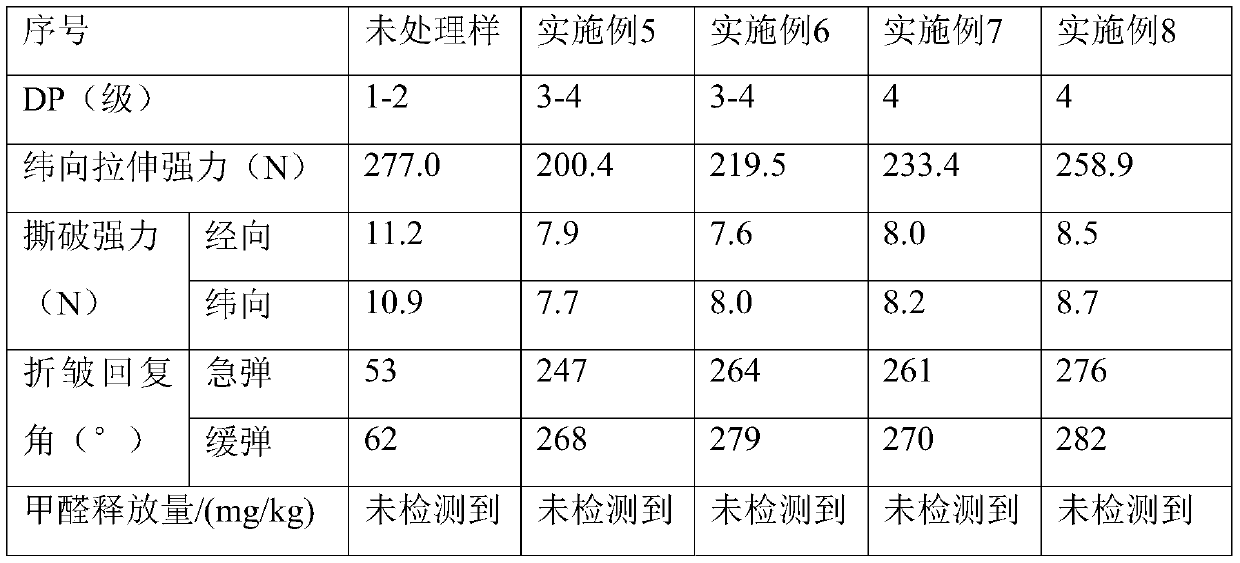

Examples

Embodiment 1

[0033] A moisture-crosslinked silicone anti-wrinkle and no-iron finishing liquid. Each liter of moisture-crosslinked silicone anti-wrinkle and no-iron finishing liquid is made of the following components:

[0034] Anti-shrink and anti-wrinkle resin NBD: 200g / L, catalyst CS-300: 100g / L, penetrant JFC: 2g / L, hydrophilic silicone softener SS 6179-1: 40g / L, self-crosslinking silicone finishing agent SS 6186: 30g / L, organic silicon crosslinking agent SS 6175: 10g / L, the rest is deionized water.

[0035] A preparation method of the moisture-crosslinked organosilicon anti-wrinkle and permanent-iron finishing liquid includes the following steps:

[0036] According to the stated ratio, under normal temperature conditions, it will be added to shrink-proof anti-wrinkle resin NBD, catalyst CS-300, penetrant JFC, hydrophilic silicone softener SS 6179-1, self-crosslinking silicone finishing agent SS 6186, organic The silicon crosslinking agent SS 6175 was added with deionized water and stirred to...

Embodiment 2

[0040] A moisture-crosslinked silicone anti-wrinkle and no-iron finishing liquid. Each liter of moisture-crosslinked silicone anti-wrinkle and no-iron finishing liquid is made of the following components:

[0041] Anti-shrink and anti-wrinkle resin NBD: 230g / L, catalyst CS-300: 105g / L, penetrant JFC: 2g / L, hydrophilic silicone softener SS 6179-1: 40g / L, self-crosslinking silicone finishing agent SS 6186: 30g / L, organic silicon crosslinking agent SS 6175: 10g / L, the rest is deionized water.

[0042] A preparation method of the moisture-crosslinked organosilicon anti-wrinkle and permanent-iron finishing liquid includes the following steps:

[0043] According to the stated ratio, under normal temperature conditions, it will be added to shrink-proof anti-wrinkle resin NBD, catalyst CS-300, penetrant JFC, hydrophilic silicone softener SS 6179-1, self-crosslinking silicone finishing agent SS 6186, organic The silicon crosslinking agent SS 6175 was added with deionized water and stirred to...

Embodiment 3

[0047] A moisture-crosslinked silicone anti-wrinkle and no-iron finishing liquid. Each liter of moisture-crosslinked silicone anti-wrinkle and no-iron finishing liquid is made of the following components:

[0048] Anti-shrink and anti-wrinkle resin NBD: 200g / L, catalyst CS-300: 100g / L, penetrant JFC: 2g / L, hydrophilic silicone softener SS 6179-1: 30g / L, self-crosslinking silicone finishing agent SS 6186: 45g / L, organic silicon crosslinking agent SS 6175: 15g / L, the rest is deionized water.

[0049] A preparation method of the moisture-crosslinked organosilicon anti-wrinkle and permanent-iron finishing liquid includes the following steps:

[0050] According to the stated ratio, under normal temperature conditions, it will be added to shrink-proof anti-wrinkle resin NBD, catalyst CS-300, penetrant JFC, hydrophilic silicone softener SS 6179-1, self-crosslinking silicone finishing agent SS 6186, organic The silicon crosslinking agent SS 6175 was added with deionized water and stirred to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com