Crease-resistant non-ironing finishing agent for shirt fabric, preparation method and crease-resistant non-ironing treatment method

A non-iron finishing and fabric technology, which is applied in fiber treatment, textiles and papermaking, and fibers that affect crease behavior, and can solve problems such as performance degradation, reduced shirt comfort, and poor durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

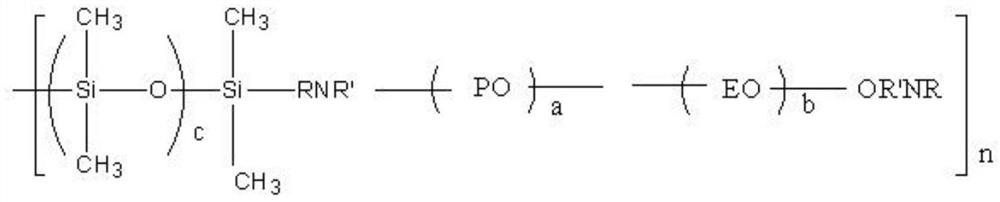

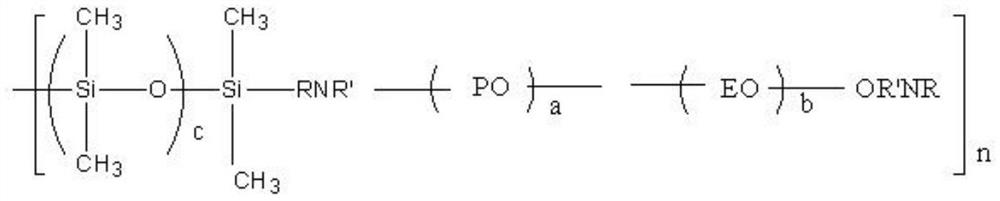

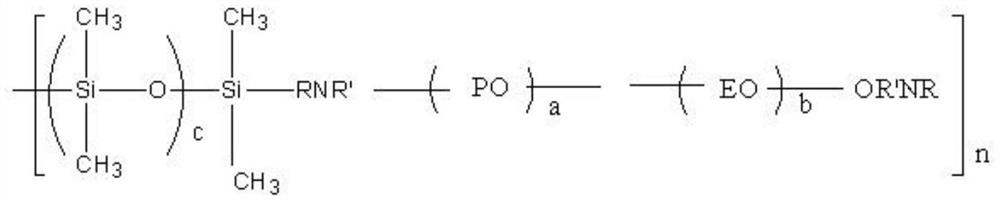

[0027] The anti-wrinkle and non-ironing finishing agent for shirt fabric in the present embodiment comprises the following components in weight percentage: 10% anti-shrinkage anti-wrinkle resin, 10% stiff finishing agent, 1% fiber protection agent, 1% hydrophilic Silicone finishing agent, 2% dispersant, 1% organic acid, 1% bacteriostatic agent, and the balance is deionized water.

[0028] The anti-shrinkage and anti-wrinkle resin includes 20% IF-12 resin, 5% fatty alcohol polyoxyethylene ether and 6% hydroxypropyl methylcellulose, and the balance is solvent, preferably alcohols such as ethanol and isopropanol , Glycerin, etc.

[0029] The stiff finishing agent includes 10% polyvinyl alcohol, 10% polyacrylate, 5% modified starch, and the solvent is deionized water. Polyvinyl alcohol is used to enhance the stiffness of fabrics, polyacrylate is used to enhance the washing fastness of fabrics, and modified starch is used as an auxiliary of polyvinyl alcohol to increase the stiffn...

Embodiment 2

[0044] The anti-wrinkle and non-ironing finishing agent for shirt fabric in the present embodiment comprises the following components in weight percentage: 20% anti-shrinkage anti-wrinkle resin, 15% stiff finishing agent, 4% fiber protection agent, 6% hydrophilic Silicone finishing agent, 5% dispersant, 3% organic acid, 2% bacteriostatic agent, and the balance is deionized water.

[0045] The anti-shrink and anti-wrinkle resin consists of 25% IF-12 resin, 8% fatty alcohol polyoxyethylene ether, 8% hydroxypropyl methylcellulose and solvent.

[0046] The stiffening agent included 22% polyvinyl alcohol, 15% polyacrylate, 8% modified starch and deionized water.

[0047] The fiber protection agent and the hydrophilic silicone finishing agent are the same as in Example 1, and the dispersant, organic acid, and bacteriostatic agent can be selected according to actual needs.

[0048] The preparation method of the anti-wrinkle and non-ironing finishing agent for shirt fabrics in this e...

Embodiment 3

[0054] The anti-wrinkle and non-ironing finishing agent for shirt fabric in the present embodiment comprises the following components in weight percentage: 30% anti-shrinkage anti-wrinkle resin, 20% stiff finishing agent, 6% fiber protection agent, 10% hydrophilic Silicone finishing agent, 8% dispersant, 5% organic acid, 3% bacteriostatic agent, and the balance is deionized water.

[0055] The anti-shrink and anti-wrinkle resin consists of 30% IF-12 resin, 12% fatty alcohol polyoxyethylene ether, 10% hydroxypropyl methylcellulose and solvent.

[0056] The stiffening agent includes 35% polyvinyl alcohol, 20% polyacrylate, 10% modified starch and deionized water.

[0057] The fiber protection agent and the hydrophilic silicone finishing agent are the same as in Example 1, and the dispersant, organic acid, and bacteriostatic agent can be selected according to actual needs.

[0058] The preparation method of the anti-wrinkle and non-ironing finishing agent for shirt fabrics in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com