Fabricated composite bridge surface system of U-shaped bolt connecting parts with adjustable screw pitch

A connector and assembly technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of large welding workload, low efficiency, complex process, etc., and achieve the effect of optimizing the overall mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

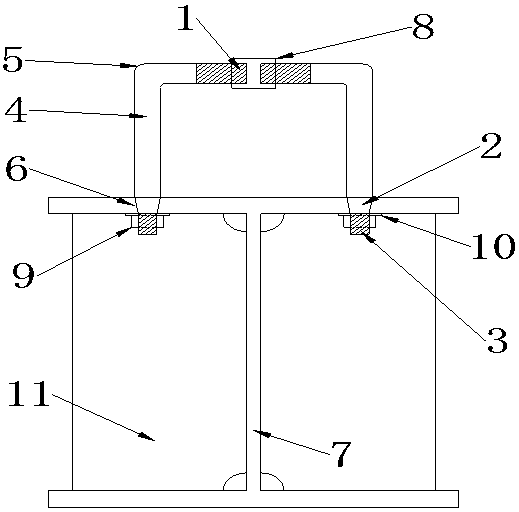

[0032] like Figure 9 As shown, a prefabricated composite bridge deck system with adjustable U-bolt connectors, including U-bolt shear connectors and I-shaped steel beams 7, along the length direction of the I-shaped steel beams 7 at intervals U-bolt shear connectors are arranged on the upper flange plate at a certain distance, and concrete is poured on the upper flange plate of the I-beam 7 to form a concrete bridge deck 12. In this embodiment, the concrete bridge deck 12 One side of the bridge deck is provided with a concrete bridge deck slab edge occlusal part 16, which can be used to connect other parts of the concrete bridge deck 12, and the concrete bridge deck 12 is hoisted on the cover beam 14 above the pier 13 to form a steel-concrete assembled bridge deck system.

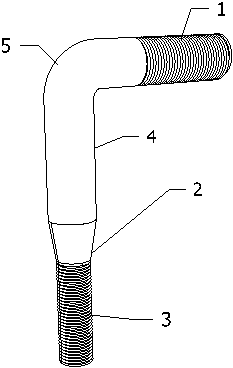

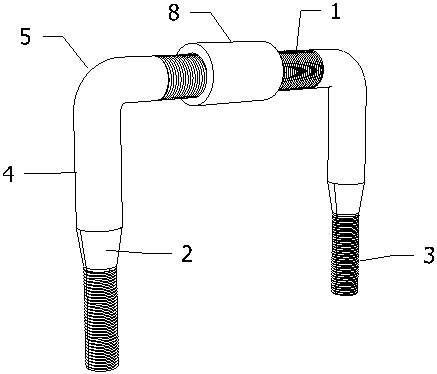

[0033] The U-shaped bolt shear connector is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com