Segment structure for preventing upward floating of shield tunnel and construction method of segment structure

A technology for shield tunneling and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as the longitudinal axis of the tunnel does not meet the design requirements, partial or overall floating, and deviation from the design axis, etc., to achieve a simple and effective structure, The effect of avoiding pressure instability and reducing the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

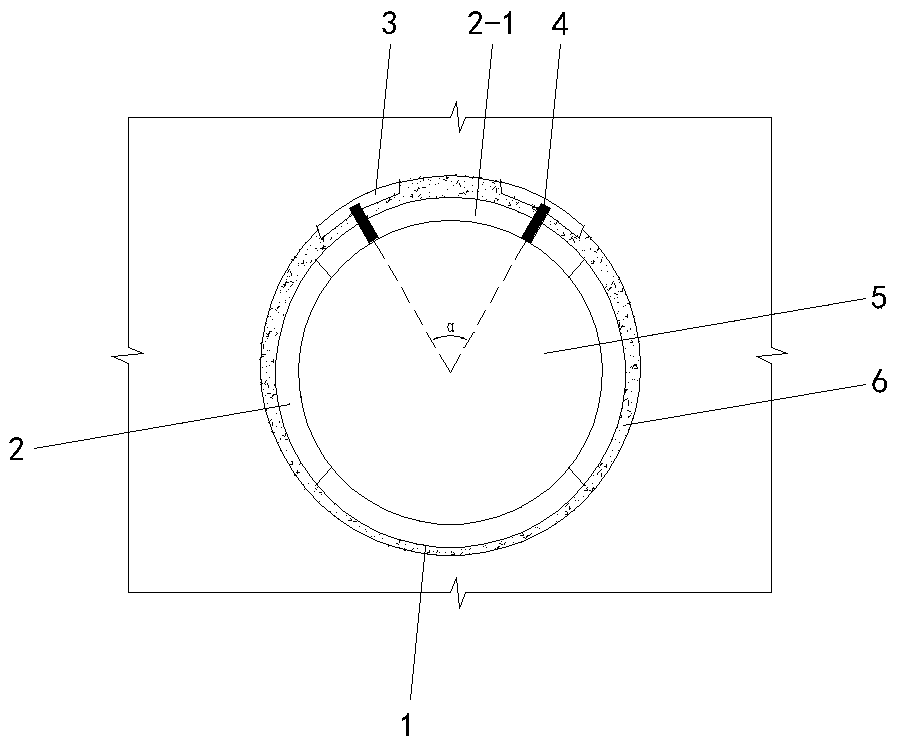

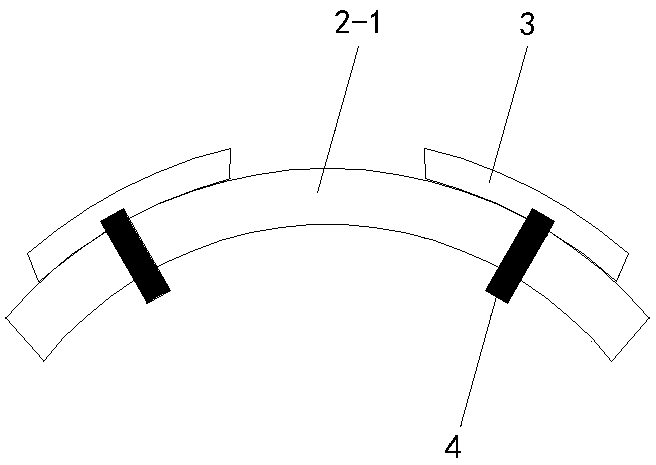

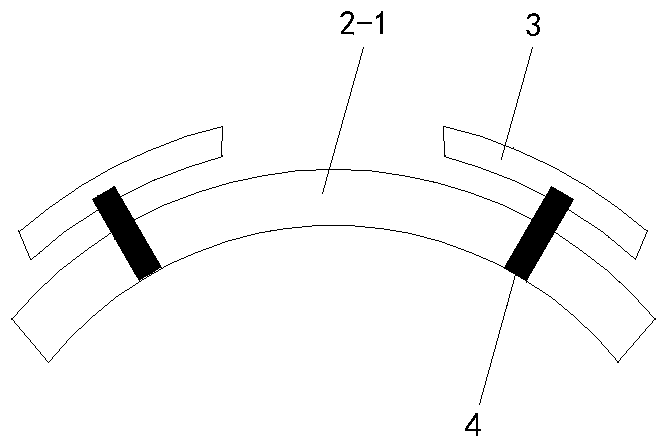

[0022] Specific implementation mode one: as Figure 1~Figure 4 As shown, the present invention discloses an anti-floating segment form of a shield tunnel, which includes a plurality of segment ring units 1, and the plurality of segment ring units 1 are arranged in sequence along the extending direction of the shield tunnel 5, each The segment ring unit 1 is assembled and enclosed by a plurality of segments 2, and one of the segments 2 is used as a capping segment 2-1, and the capping segment 2-1 is provided with a grouting hole , the segment 2 is made of steel skeleton and high-strength anti-seepage prestressed concrete to ensure reliable load-carrying and waterproof performance, and every other segment ring unit 1 capping segment 2-1 is installed with two anti-floating Sheet 3, the two anti-floating sheets 3 are arc-shaped sheets and are symmetrically arranged on the top of the capping segment 2-1 along the vertical central axis of the corresponding segment ring unit 1, the c...

specific Embodiment approach 2

[0023] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of specific embodiment 1. The support screw 4 is arranged radially along the corresponding segment ring unit 1, and the capping segment 2-1 corresponding to the support screw 4 is pre-embedded and fixed with threads The casing, the support screw 4 is screwed to the threaded casing, the threaded casing should be welded and fixed with the steel skeleton in the capping segment 2-1 as a whole, and the inner surface of the anti-floating sheet 3 corresponding to the outer end of the support screw 4 is recessed There is a top groove, and the outer end of the support screw 4 is supported in the top groove. It is advisable to set two support screws 4 for each anti-floating piece 3, and the corresponding capping segment 2-1 is evenly pre-embedded and fixed with four threaded sleeves .

specific Embodiment approach 3

[0024] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of the second specific embodiment. The support screws 4 of the two anti-floating sheets 3 are symmetrically arranged one by one along the vertical central axis of the corresponding segment ring unit 1, and each symmetrical The angle between the two supporting screw rods 4 is α, and α is 60°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com