Axial swirl vane for rotational flow combustor and arrangement thereof

A swirl burner and swirl vane technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as high pollutant emissions, energy waste, and insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

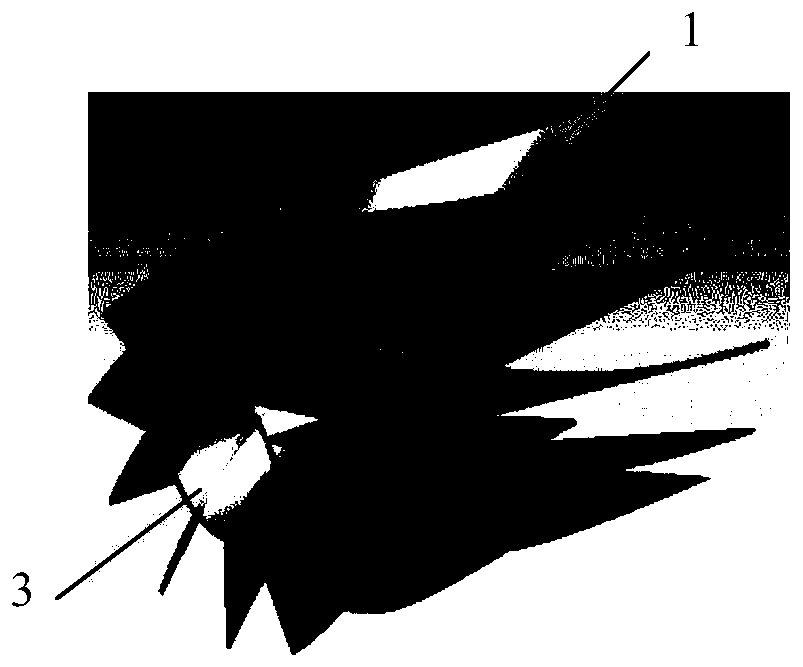

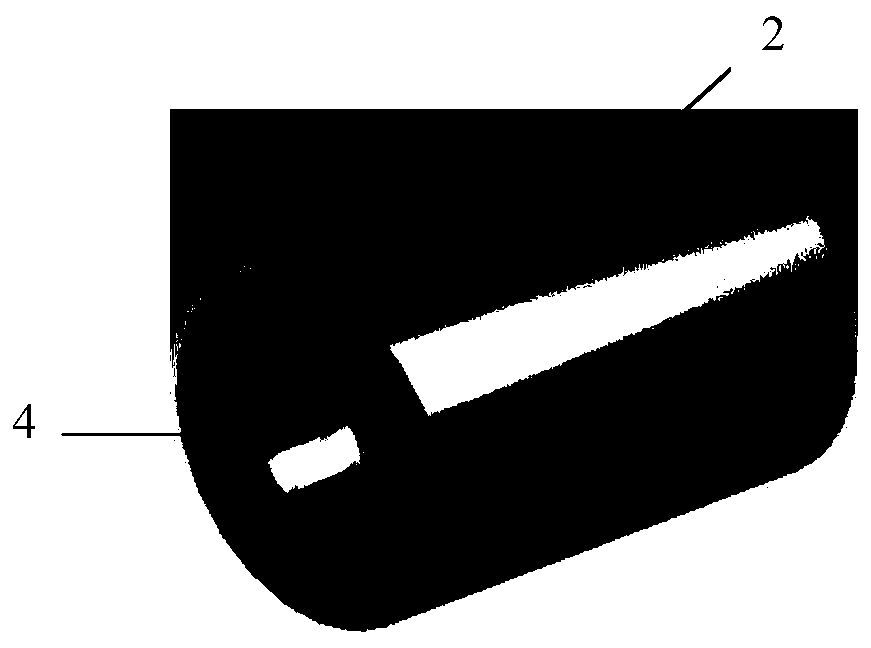

[0018] Please refer to Figure 1 to Figure 3 ,in, figure 1 It is the plane expansion diagram of the blade in the present invention; figure 2 is a schematic diagram of the connection of swirl blades on the inner side of the casing; image 3 It is a schematic diagram of the connection of swirl blades on the inner and outer sides of the casing.

[0019] The invention discloses an axial swirl vane for a swirl burner and its arrangement, comprising a sleeve 2 and a swirl vane 1 . The sleeve 2 is a hollow annular cylinder; the swirl vane 1 is embedded in the hollow annular cylinder; the outer edge of the swirl vane 1 is welded on the outer cylindrical surface of the hollow annular cylinder; The inner edge of the swirl vane 1 is welded on the inner cylindrical surface 3 of the hollow annular cylinder; there are multiple swirl vanes 1, and all the swirl vanes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com