Air cooler and method for enabling air cooler to drain no water

A cooling fan and fan technology, applied in the direction of preventing condensed water, heating methods, noise suppression, etc., can solve problems such as drainage troubles, and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

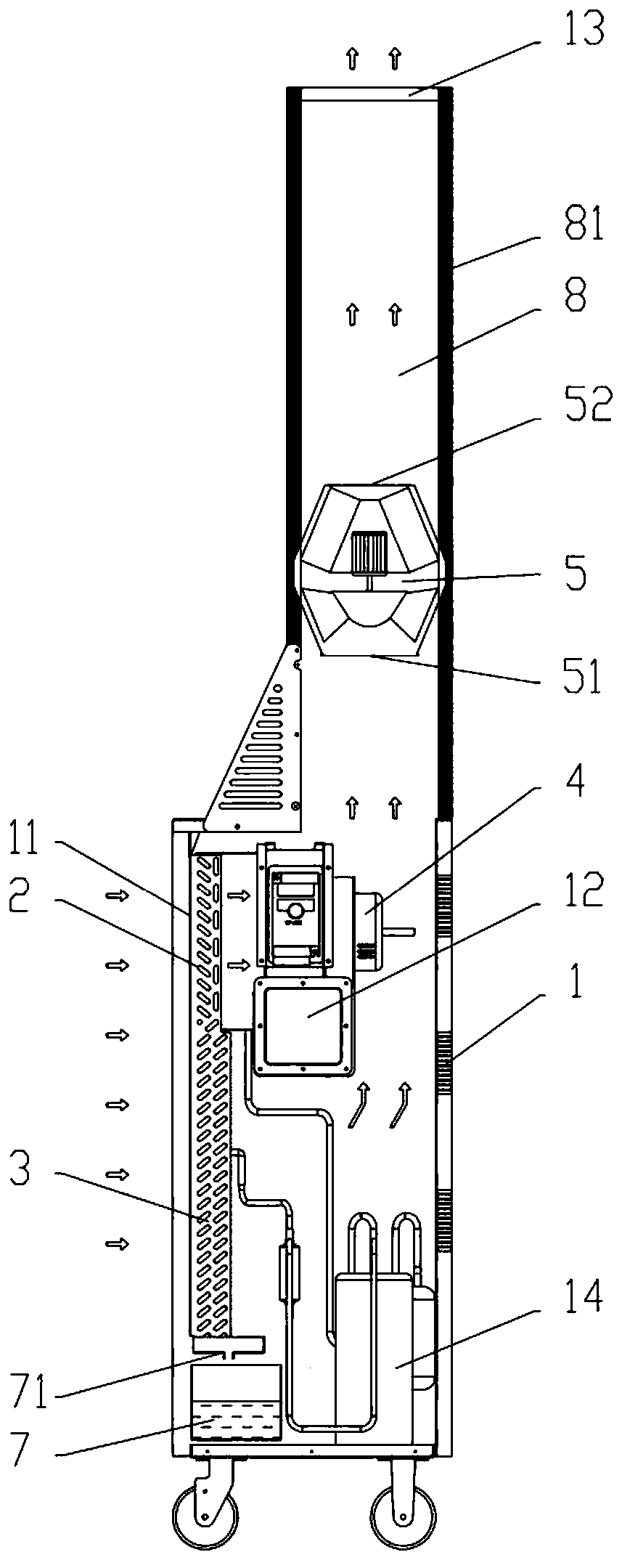

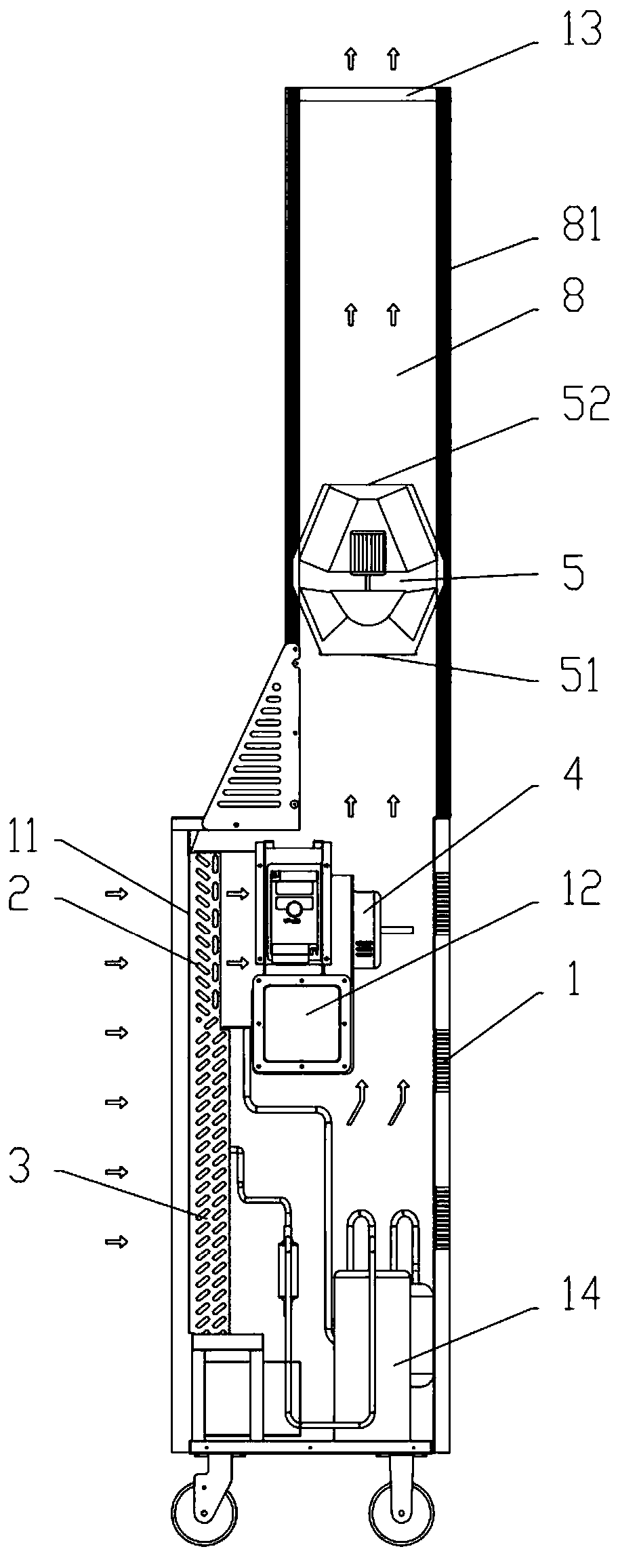

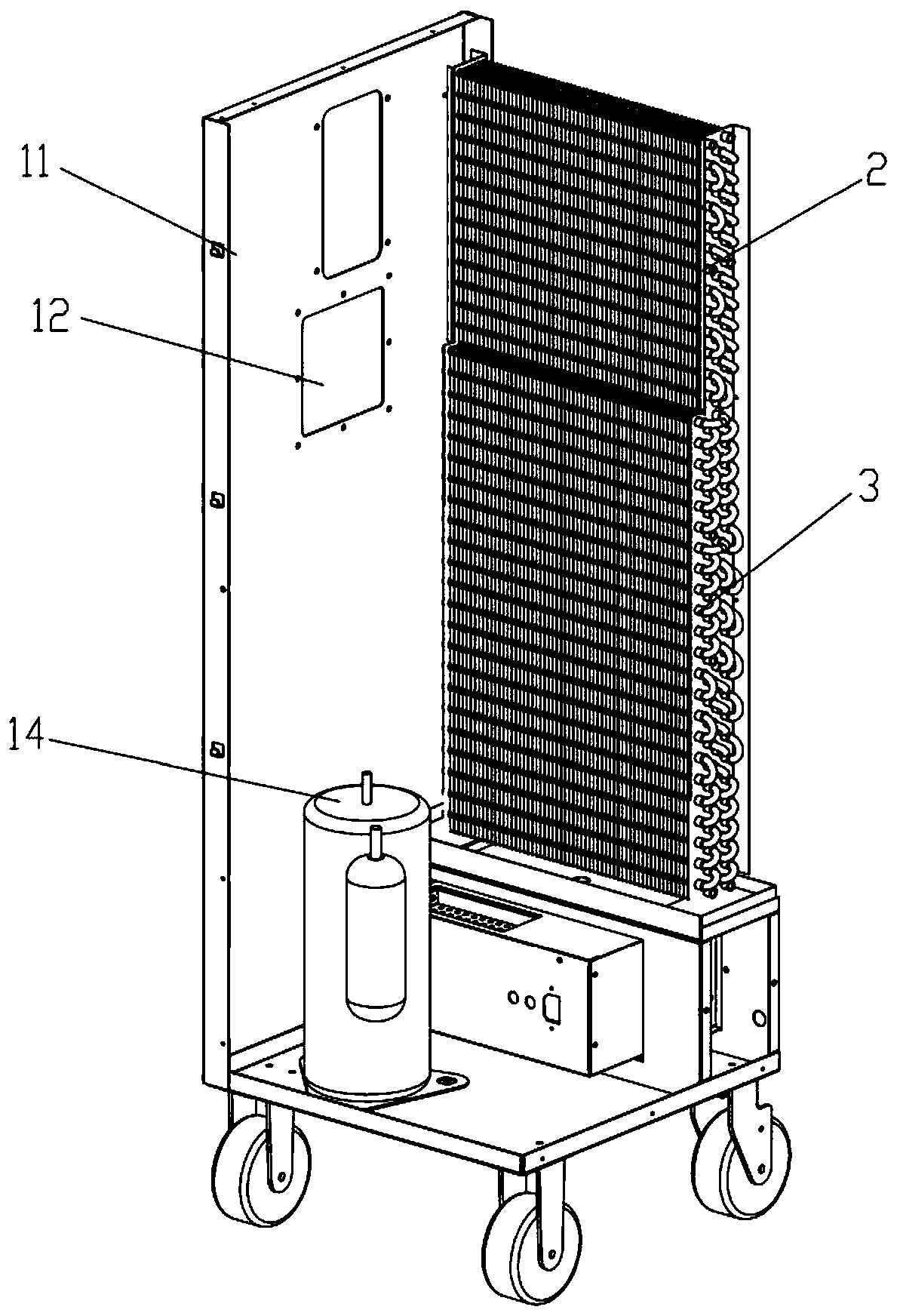

[0038] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a cold air blower 100, comprising a casing 1, the casing 1 is provided with an air inlet 11, a cold air outlet 12 and a hot air outlet 13, and the casing 1 includes a compressor 14, an evaporator 2, a condenser 3, a hot air Fan 5 and air-cooling fan 4, evaporator 2 includes evaporation straight pipes and cooling fins arranged vertically to each other, condenser 3 includes condensing straight pipes 31 and cooling fins arranged vertically to each other, and evaporator 2 is arranged above the condenser 3 , and the cooling fins and heat dissipation fins are arranged vertically, and are arranged at intervals up and down. The surface of the heat dissipation fins is provided with a hydrophilic layer. Located on the side wall of the casing 1, the hot air outlet 13 is arranged on the top of the casing 1, a hot air pipeline 8 is arranged below the hot air outlet 13, and a hot air blower 5 ...

specific Embodiment approach

[0070] 1. Increasing the number of rows of straight condensing pipes in the first direction is equivalent to extending the length of the condenser, that is, the distance between two adjacent straight condensing pipes along the first direction remains unchanged, and increasing the straight condensing pipes along the first The number of settings for the direction.

[0071] 2. Reduce the arrangement spacing of the straight tube array of the condenser and increase the distribution density of the straight tubes. That is, the distance between two adjacent straight condensation pipes along the first direction or the second direction is reduced.

[0072] 3. Increase the number of condensing straight pipe columns.

[0073] Therefore, in a specific implementation of the present embodiment, compared with the prior art, some parameters of the condenser are significantly different: the row spacing of the condensing straight pipes in the condenser is reduced from 21 mm to 18 mm, which is r...

Embodiment 2

[0083] See figure 1 , figure 2 , including the air cooler 100 of Embodiment 1 of the above-mentioned air cooler, the axis of the air inlet 11 and the axis of the hot air outlet 13 are vertically arranged, the air inlet 11 and the hot air outlet 13 are respectively located on both sides of the condenser 3, and the hot air outlet The tuyere 13 is located above the air inlet 11 .

[0084] The axis of the air inlet is set perpendicular to the axis of the hot air outlet. The air inlet and the hot air outlet are respectively located on both sides of the condenser, and the hot air outlet is located above the air inlet. The hot air fan will transport the gas absorbed from the air inlet to the When the hot air is out of the air, it needs to turn and rise.

[0085] See figure 1 , figure 2 The hot air fan 5 is provided with an air inlet 51 and an air outlet 52, the axis of the air inlet 51 is arranged coaxially with the axis of the air outlet 52, and the axis of the air outlet 52 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com