Absorption type heat exchange system

A heat exchange system and absorption technology, which can be used in adsorption machines, absorbents/adsorbents, heat pumps, etc., and can solve problems such as widening the scope of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each figure, the same or similar reference numerals are assigned to mutually identical or corresponding components, and overlapping descriptions will be omitted.

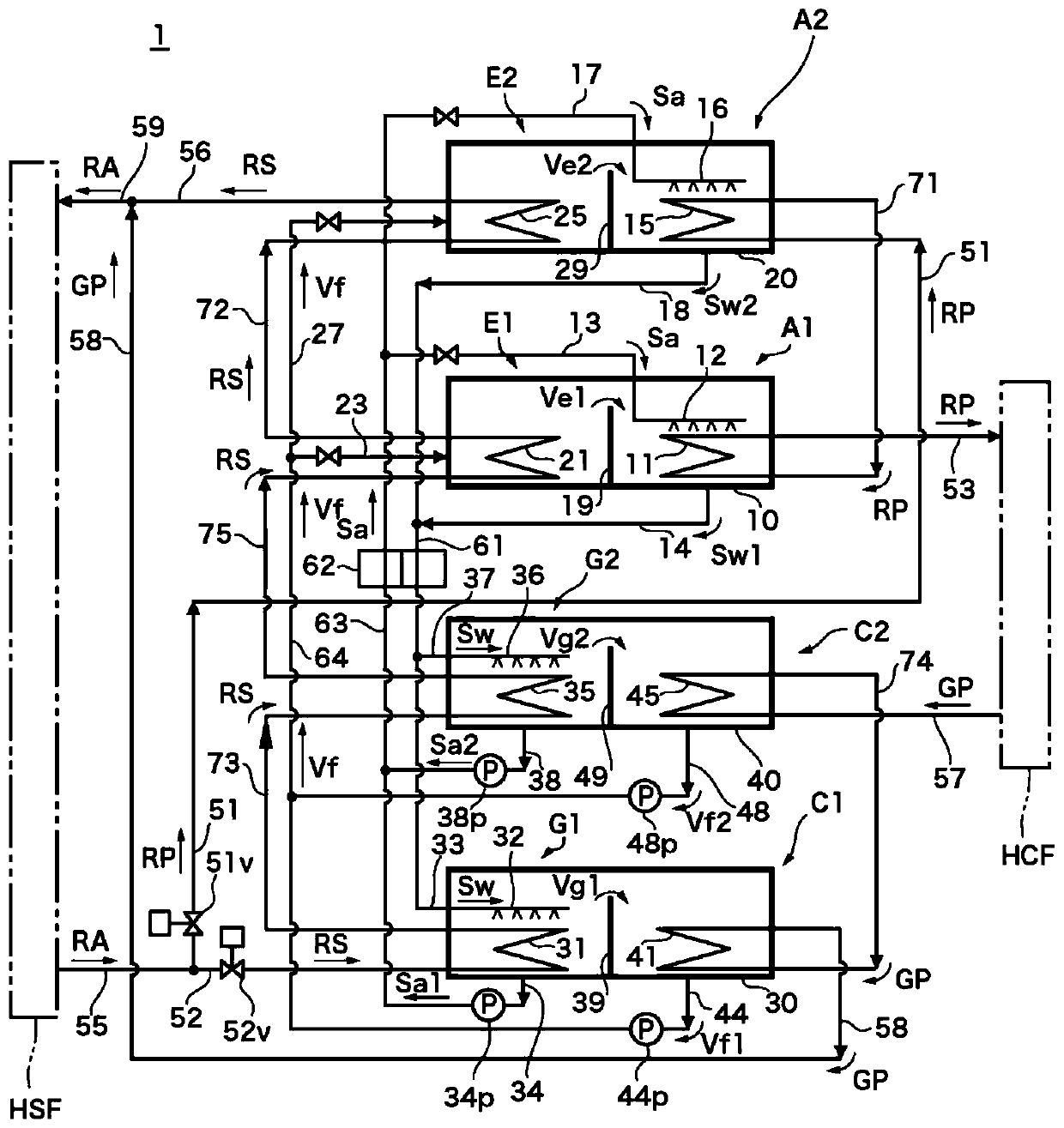

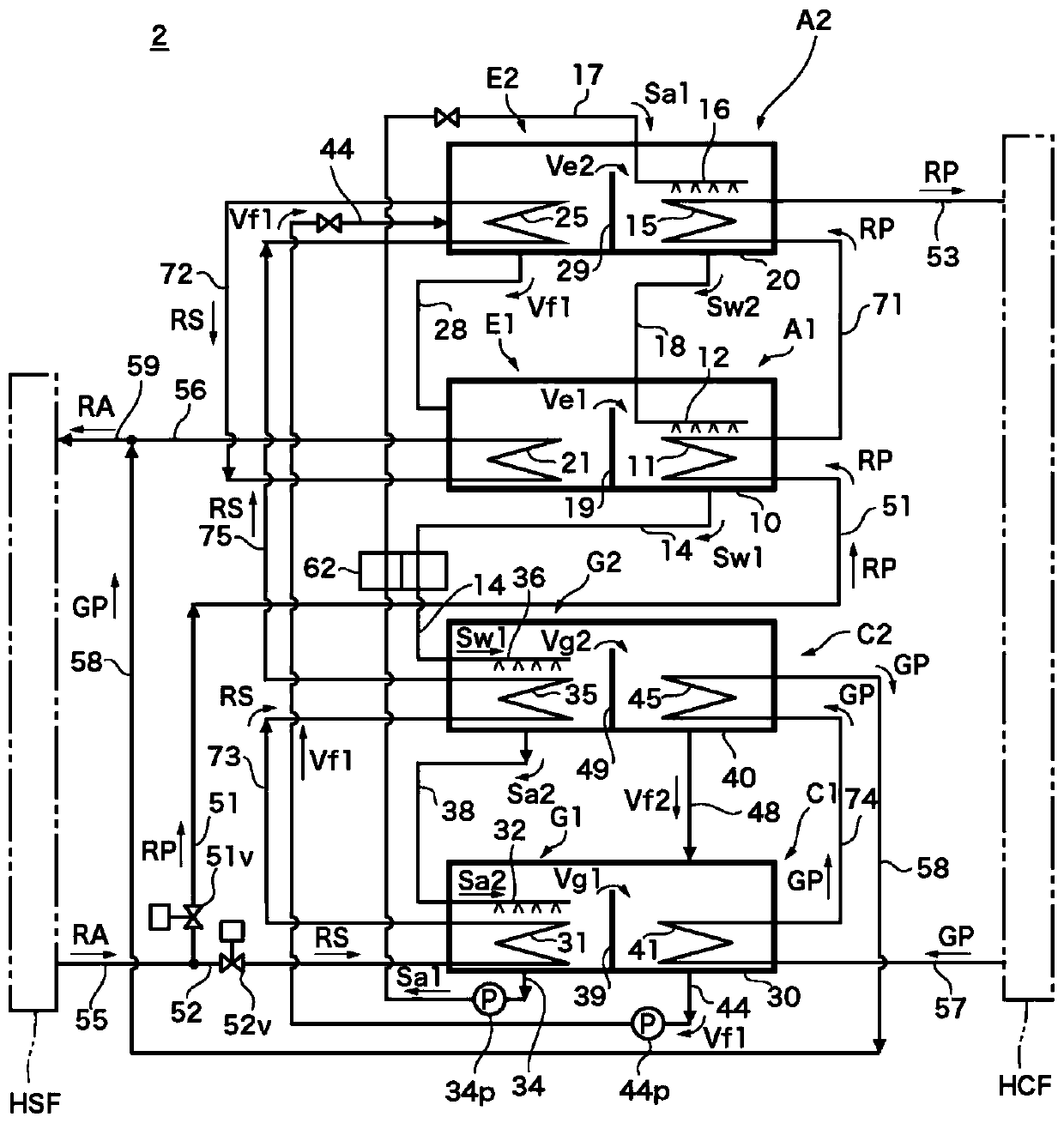

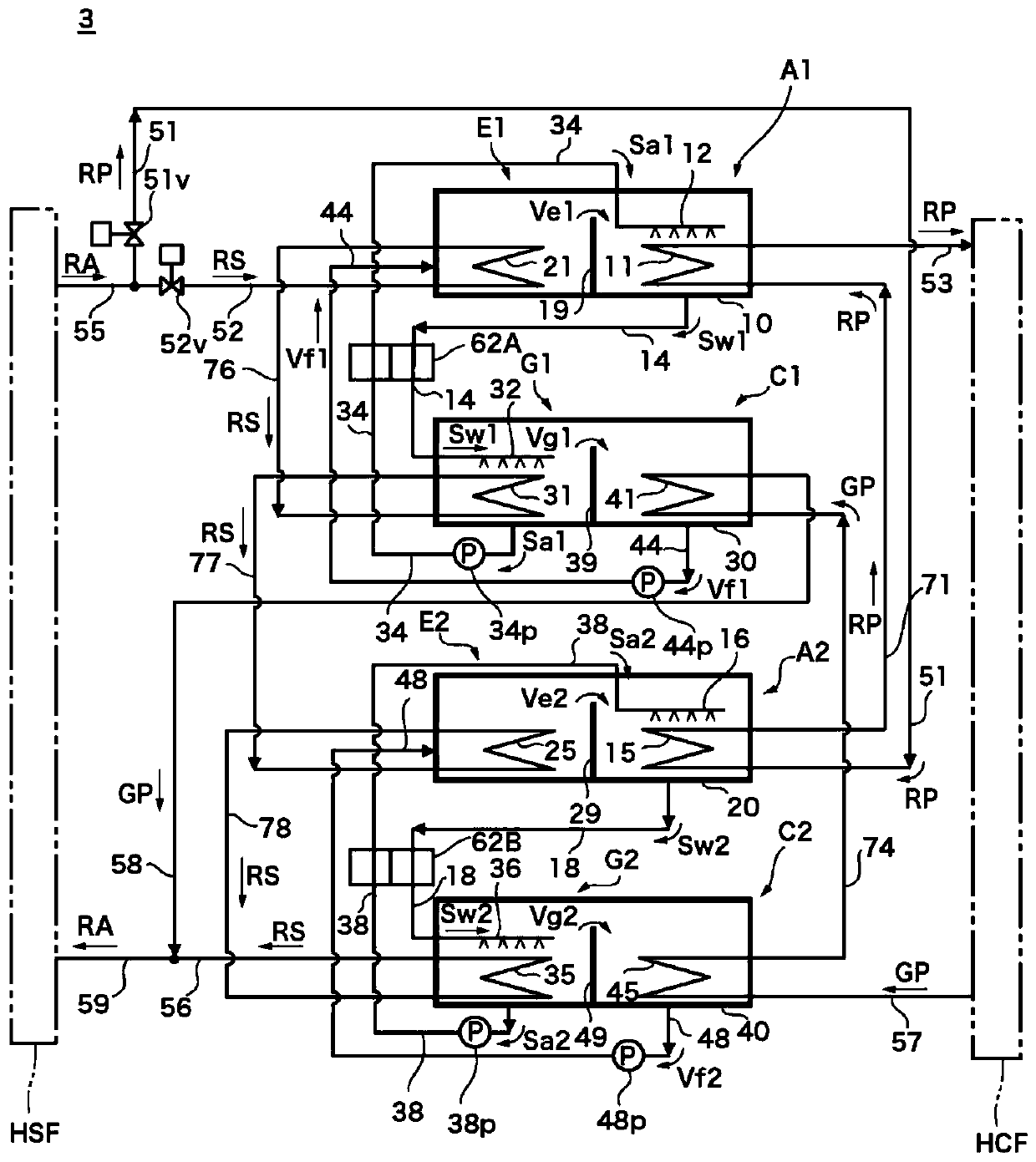

[0044] First, refer to figure 1 The absorption heat exchange system 1 according to the first embodiment of the present invention will be described. figure 1 is a schematic system diagram of the absorption heat exchange system 1 . The absorption heat exchange system 1 is an absorption heat pump cycle using the absorption liquid and the refrigerant, so that the temperature ratio of the temperature rise fluid RP flowing out from the absorption heat exchange system 1 toward the heat utilization equipment HCF is transferred to the absorption heat exchange system as the driving heat source. The exchange system 1 is a system that transfers heat so that the temperature of the driving heat source flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com