Numerical simulation method for multi-pass rolling process of ultra-thick plate blank

A numerical simulation and multi-pass technology, applied in CAD numerical modeling, electrical digital data processing, special data processing applications, etc., can solve the problems of low simulation accuracy, long calculation time, complex deformation process, etc., and achieve high simulation accuracy , Eliminate casting defects and enhance the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

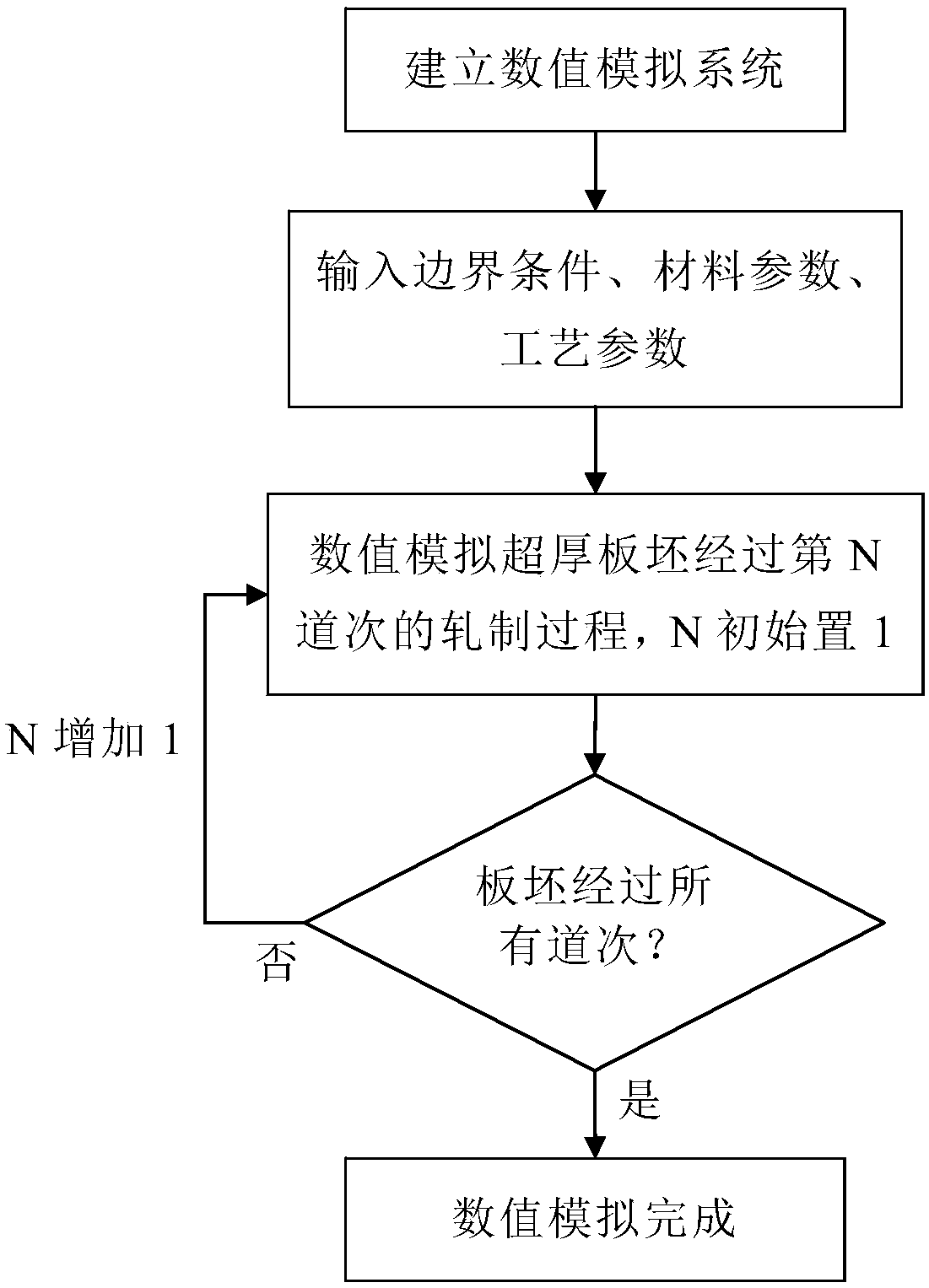

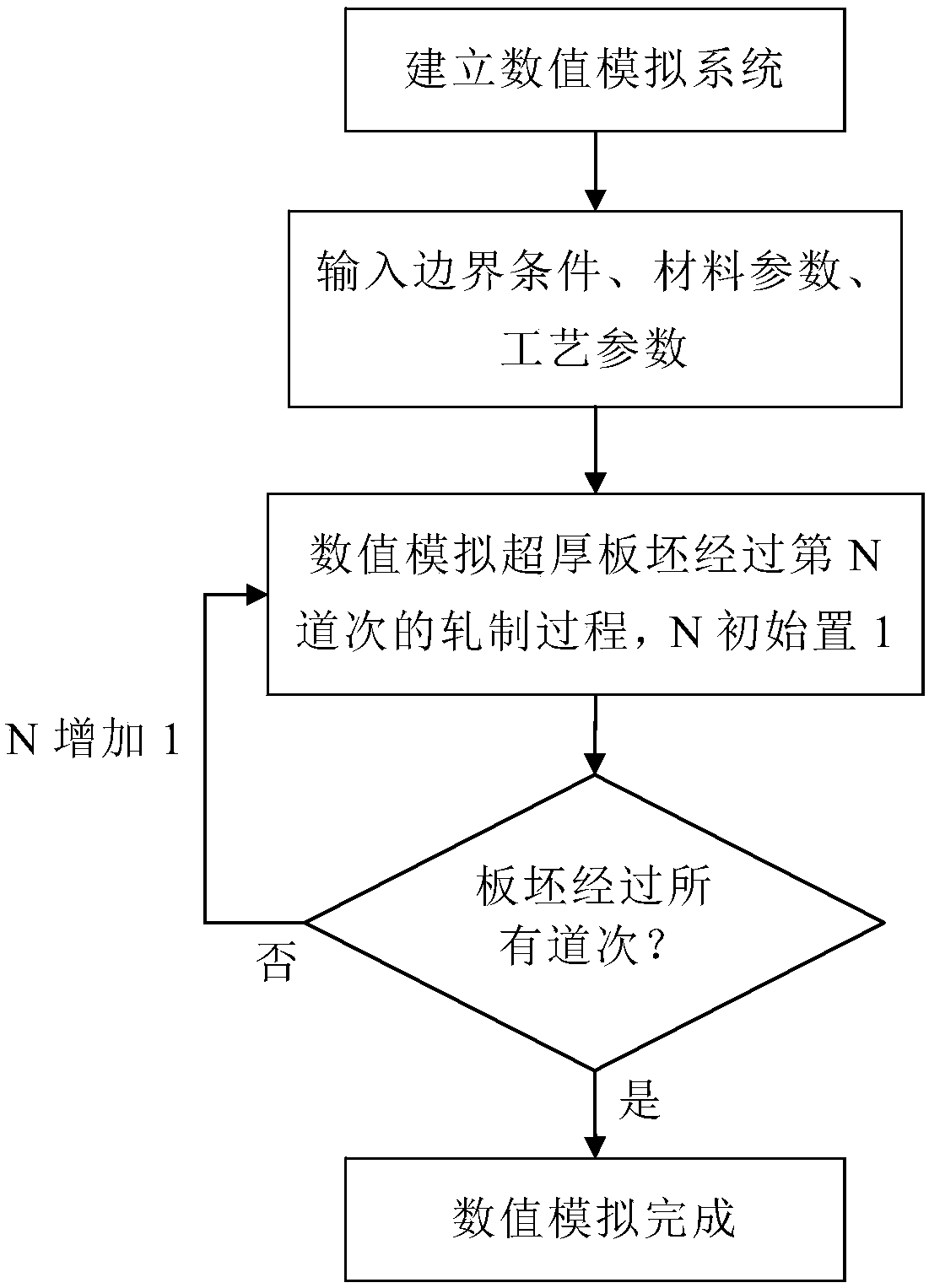

[0026] Such as figure 2 , The numerical simulation method of the multi-pass rolling process of ultra-thick slab of the present invention includes the steps:

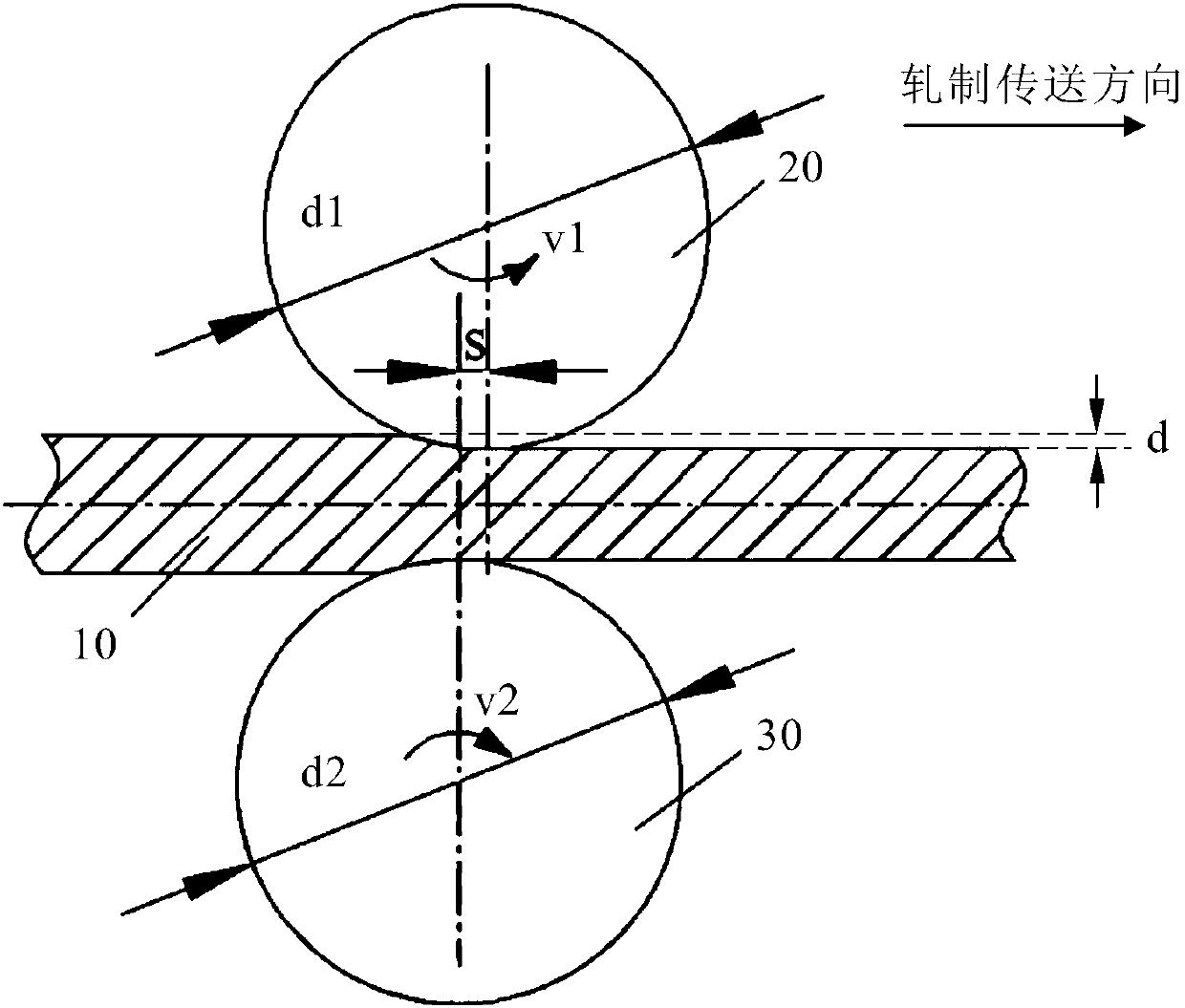

[0027] 1) Establish a numerical simulation system. The numerical simulation system includes heat transfer model, material model, friction model, constitutive equation, structure evolution model, and the geometry of upper and lower rolls 20, 30 and ultra-thick slab 10 established by CAD software model;

[0028] 2) Input boundary conditions, material parameters, and process parameters to the numerical simulation system;

[0029] 3) Numerical simulation of the rolling process of ultra-thick slab 10 through the Nth pass:

[0030] 3-1) Based on the numerical simulation system, the finite element method (a well-known algorithm) is used to numerically simulate step by step that the slab 10 contacts the upper and lower rolls 20, 30 and enters the unsteady deformation rolling stage;

[0031] 3-2) Realize the transfer of various physical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com